UFC 3-280-03

23 JULY 2003

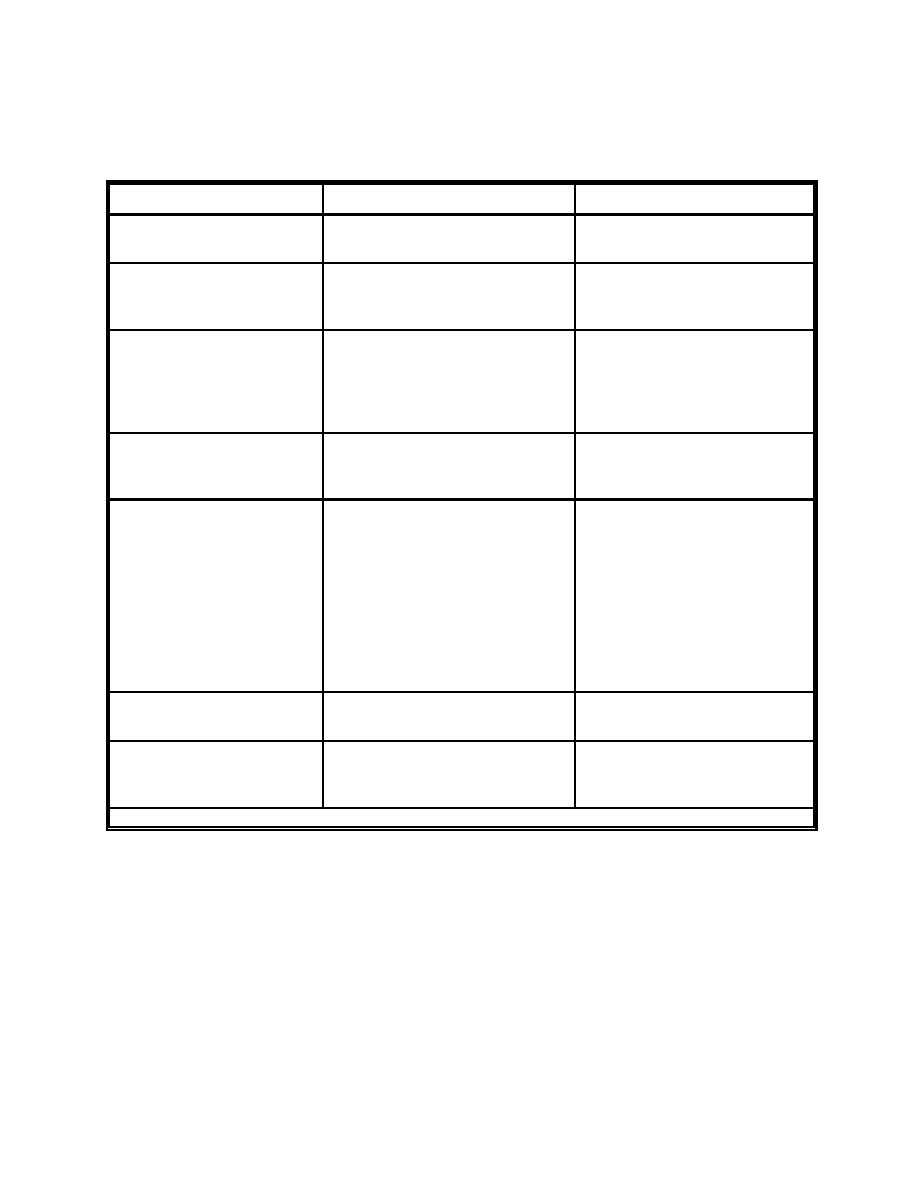

Table 2-9. Most common design and operational shortcomings

of filter press installations.

Shortcomings

Resultant Problems

Solution

Improper conditioning

Blinding of filter cloth and poor cake

Switch conditioning chemicals or

chemicals utilized.

release.

dosages.

Increase frequency of washing.

Insufficient filter cloth washing.

Blinding of filter cloth, poor cake

release, longer cycle time required,

wetter cake.

Inability to transport dewatered

Cake buildup and spillage onto the

Install cake breakers; redesign

cake from dewatering building.

floor.

angle of screw conveyors or belt

conveyors to 15 degrees maximum

angle. Alternatively, use a heavy-

duty flight conveyor.

Change media.

Improper filter cloth media

Poor cake discharge; Difficult to

specified.

clean.

Poor cake release.

(1) Try two-stage compression

Inadequate facilities when

"pumping" cycle with first stage at

dewatering a digested sludge

low pressure to build up dewatered

with a very fine floc.

sludge on the filter media before

increasing to the second-stage

higher operating pressure.

(2) If this fails, vary conditioning or

install precoat storage and feed

facilities.

Feed sludge is too dilute for

Long cycle time and reduced

Thicken sludge before feeding to

efficient filter press operation.

capacity.

filter press.

Sludge feed at only one end of

Unequal sludge distribution within the

Use equalizing tank or additional

large filter press.

press.

pump to feed at opposite end of

press.

Source:

EPA (1982)

Remedial measures for this problem include the use of reinforcement, such

as an extra layer of material, or use of a different type of material, or the use of stainless

steel covers that fit directly over the cloth media and stay boss. However, if the former

method is used, care should be taken to ensure that the additional layer of thickness is

equal to that around the perimeter of the plate to ensure proper sealing and to minimize

the potential for plate deflection.

2-9.1.1.3 Stay Boss Deterioration. Stay bosses deteriorate from excessive wear

caused by plate deflection. This wear increases the flexing of the plate and ultimately

breaks the plate. Therefore, stay bosses should be regularly inspected for deterioration

and repaired as required. Stay boss deterioration can also be minimized by following

the remedial measures listed for plate deflection in Subparagraph 2-9.1.1.1.

2-78

Previous Page

Previous Page