TM 5-814-7

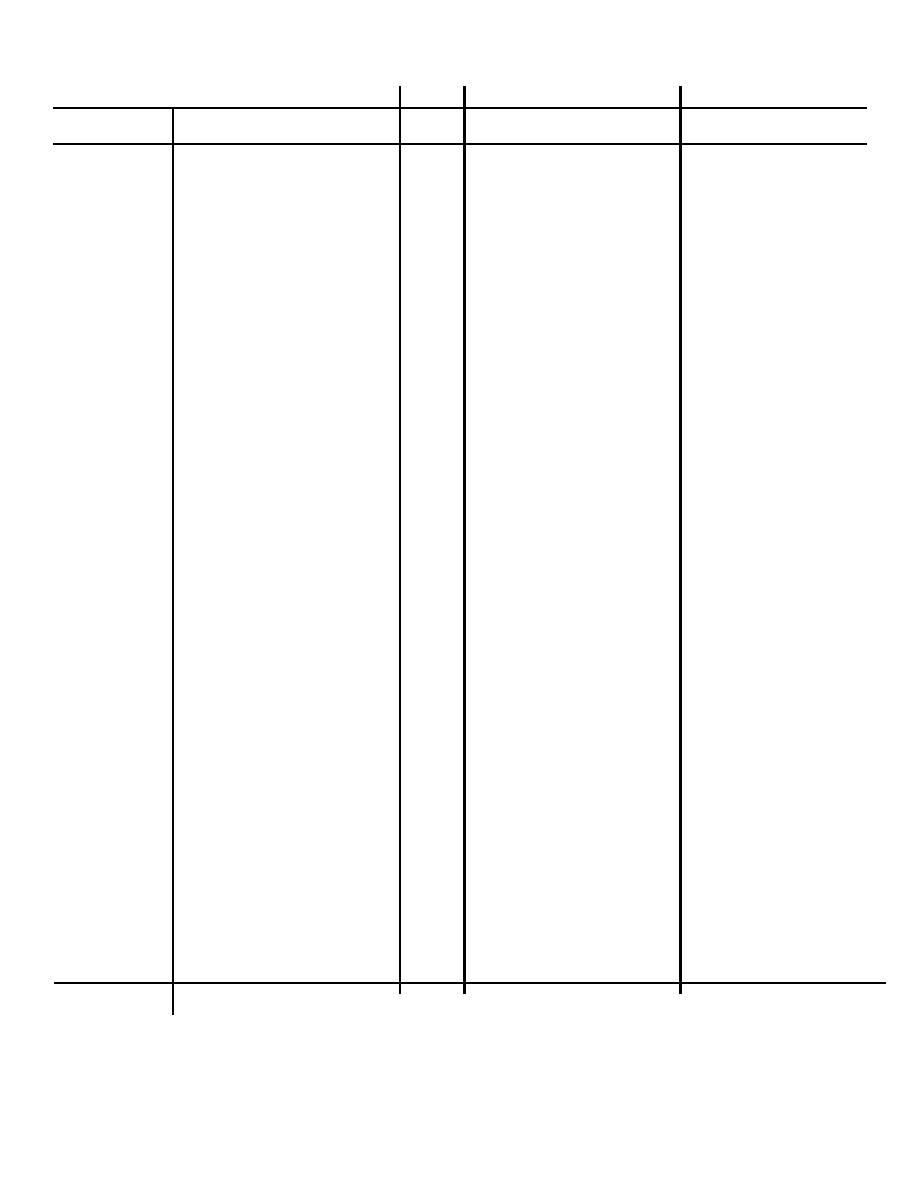

Table 6-2. Summary of Liner Types

Range of

Liner material

Characteristics

costs a

Advantages

Disadvantages

Soils:

Compacted clay

Compacted mixture of onsite

L

High cation exchange capacity; re-

Organic or inorganic acids or

soils to a permeability of 10-7

soils

sistant to many types of

bases may solubilize portions

cm/sec

leachate

of clay structure

Soil-bentonite

Compacted mixture of onsite

L

High cation exchange capacity;

Organic or inorganic acids or

soil, water and bentonite

resistant to many types of

bases may solubilize portions

leachate

of clay structure

Admixes:

Asphalt-concrete

Mixtures of asphalt cement and

M

Resistant to water and effects of

Not resistant to organic solvents;

high quality mineral aggregate

weather extremes; stable on

partially or wholly soluble in

side slopes; resistant to acids,

hydrocarbons; does not have

bases, and inorganic salts

good resistance to inorganic

chemicals; high gas perme-

ability

Asphalt-

Core layer of blown asphalt

M

Flexible enough to conform to ir-

Ages rapidly in hot climates; not

membrane

blended with mineral fillers

regularities in subgrade; resist-

resistant to organic solvents,

and reinforcing fibers

ant to acids, bases, and inor-

particularly hydrocarbons

Soil asphalt

Compacted mixture of asphalt,

L

Resistant to acids, bases, and

Not resistant to organic solvents,

water, and selected in-place

salts

particularly hydrocarbons

soils

Soil cement

Compacted mixture of Portland

L

Good weathering in wet-dry/

Degraded by highly acidic envi-

cement, water, and selected in-

freeze-thaw cycles; can re-

ronments

place soils

sist moderate amount of alkali,

rganics and inorganic salts

Polymeric membranes:

Butyl rubber

Copolymer of isobutylene with

M

Low gas and water vapor perme-

Highly swollen by hydrocarbon

small amounts of isoprene

ability; thermal stability; only

solvents and petroleum oils;

slightly affected by oxygen-

difficult to seam and repair

ated solvents and other polar

liquids

Chlorinated

Produced by chemical reaction

M

Good tensile strength and

Will swell in presence of aro-

polyethylene

between chlorine and high den-

elongation strength; resistant

matic hydrocarbons and oils

sity polyethylene

to many inorganics

Chlorosulfonate

Family of polmers prepared by

H

Good resistance to ozone, heat,

Tends to harden on aging; low

polyethylene

reacting polyethylene with

acids, and alkalis

tensile strength; tendency to

chlorine and sulfur dioxide

shrink from exposure to sun-

light; poor resistance to oil

Elasticized

Blend of rubbery and crystalline

L

Low density; highly resistant to

Difficulties with low temper-

polyolefins

polyolefins

weathering, alkalis, and acids

atures and oils

Epichlorohydrin

Saturated high molecular weight,

M

Good tensile and test strength;

None reported

rubbers

aliphatic polethers with chloro-

thermal stability; low rate of

methyl side chains

gas and vapor permeability; re

sistant to ozone and weather-

ing; resistant to hydrocarbons,

solvents, fuels, and oils

Ethylene

Family of terpolymers of

M

Resistant to dilute concentra-

Not recommended for petroleum

propylene

ethylene, propylene, and non

tions of acids, alkalis, silicates,

solvents or halogenated sol-

rubber

conjugated hydrocarbon

phosphates and brine; tolerates

vents

extreme temperatures; flexible

at low temperatures; excellent

resistance to weather and ul-

traviolet exposure

Neoprene

Synthetic rubber based on chlor-

H

Resistant to oils, weathering,

None reported

oprene

ozone and ultraviolet radi-

ation; resistant to puncture,

abrasion, and mechanical dam-

age

Polyethylene

Thermoplastic polymer based on

L

Superior resistance to oils, sol-

Not recommended for exposure

ethylene

vents, and permeation by wa-

to weathering and ultraviolet

ter vapor and gases

light conditions

See footnote at end of table.

6-7

Previous Page

Previous Page