TM 5-814-7

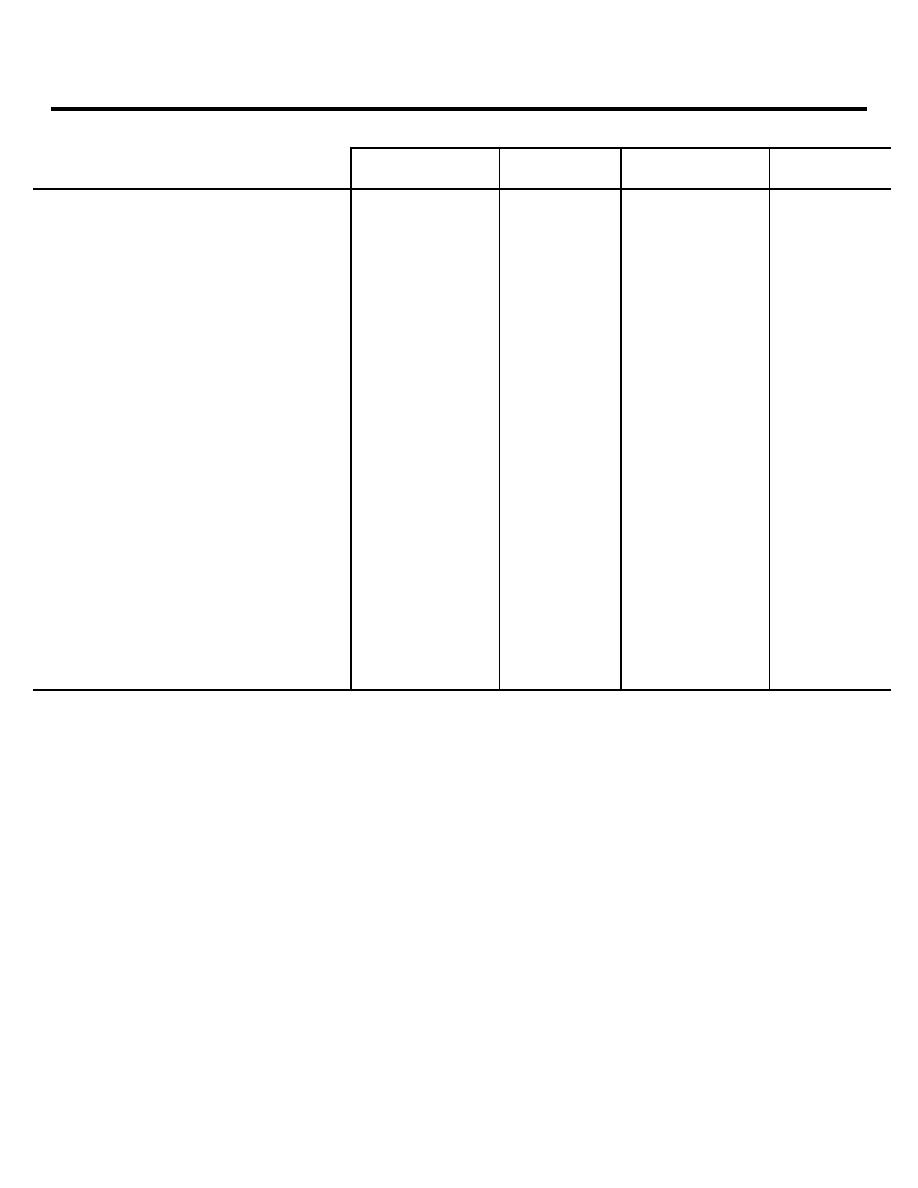

Table 6-1. Requirements for Liner Systems

Section of 40 CFR 264 Describing Requirements

K

L

M

N

Design Requirements

Surface

Waste Pile

Land Treatment

Landfill

Impoundments

Except for an existing portion, a unit must have a

264.221(a)

264.251(a)(1)

NA

264.301(a)(1)'

liner that is designed, constructed, and installed

to prevent any migration of wastes out of the unit

to the adjacent subsurface soil or ground water or

surface water at any time during the active life

(including the closure period).

Constructed of materials that have appropriate

264.221(a)

264.251(a)(1)

NA

264.301(a)(1)

chemical properties and sufficient strength and

thickness to prevent failure due to pressure

gradients (including static head and external

hydrogeologic forces), physical contact with the

waste or leachate to which they are exposed,

climatic conditions, the stress of installation, and

the stress of daily operation. Installed to cover all

surrounding earth likely to be in contact with the

waste or leachate.

Placed upon a foundation or base capable of

264.221(a)

264.251(a)(1)

NA

264.301(a)(1)

providing support to the liner and resistance to

pressure gradients above and below the liner to

prevent failure of the liner due to settlement,

compression, or uplift.

264.221(a)

264.251(a)(1)

NA

264.301(a)(1)

Liner systems must be monitored and inspected 264.226(a)

264.254(a)

NA

264.303(a)

during construction and installation, (except in the

case of existing portions of units exempted from

liners, as noted above).

Cover systems (e.g., membranes, sheets, or 264.226(a)

264.254(a)

NA

264.303(a)

coatings) must be inspected for uniformity,

damage, and imperfections (e.g., holes, cracks,

thin spots, or foreign materials) Immediately after

construction or installation

Soil-based and admixed liners and covers must 264.226(a)

264.254(a)

NA

264.303(a)

be inspected for imperfections including lenses,

cracks, channels, root holes, or other structural

non-infirmities that may cause an increase in the

permeability of the liner or cover

Adapted from 40 CFR 264

For landfills, (and surface impoundments and waste piles operated for more than 30 years), regulations include an additional

requirement that wastes not migrate into the liner during the active life of the site.

all facilities must be (1) constructed in unsaturated soil above

of a single liner of soil (clay), synthetic material, or ad- mixed

the seasonal high water table, (2) placed on a foundation

material, and a leachate collection and removal system. If

which will provide adequate support to the liner, and (3)

closure is not scheduled for 10 years or more, a synthetic liner

installed to cover all earth likely to come into contact with

is to be used, and the base liner system should consist of-

waste or leachate. Required elements of the liner system

Leachate collection and removal system above

depend on the type of facility and the anticipated period of time

primary liner

from first placement of waste to site closure.

Primary liner of synthetic material

(1) Surface impoundment liner systems depend on

Secondary liner of clay soil or synthetic material

whether the impoundment is permitted for storage (requiring

Leak detection system between liners

removal of all wastes, waste residues and liners at closure) or

(a) Alternatively, admixed materials such as

for disposal (requiring removal of free liquids, stabilization of

concrete and asphalt may be used for long-term storage if

wastes and capping at closure). The following elements are

physical and chemical analyses of their characteristics indicate

required for DA impoundments:

they will not deteriorate during the life of the waste pile.

Primary synthetic liner

Admixed liners are preferred for waste piles where repeated

Secondary (clay soil or synthetic) liner

removal and replacement of wastes may occur, since synthetic

Leak detection system

membrane liners could be easily damaged by the required

Monitoring wells

waste-handling equipment, and exposed areas of clay liners

(2) Waste piles, which can be permitted only as

could dry out and crack. Reinforced concrete with appro-

storage facilities, require base liner systems consisting

6-3

Previous Page

Previous Page