UFC 3-260-02

30 June 2001

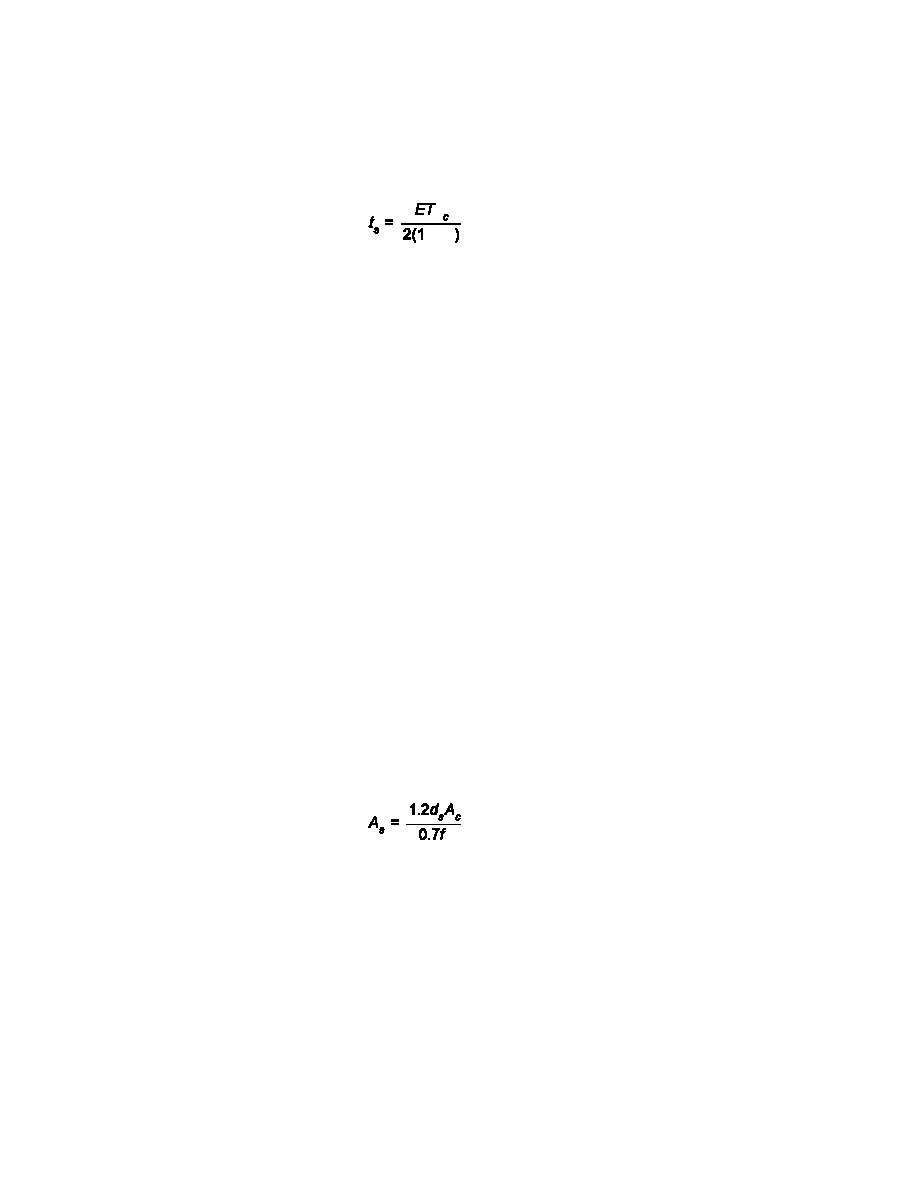

d. Temperature Warping Stress. The temperature warping stress results from the development of a

temperature gradient through the prestressed concrete pavement thickness and can be determined by:

,

(16-4)

&<

where

ts = temperature warping stress, psi

T = difference in temperature in degrees Fahrenheit between the top and bottom of the

prestressed concrete pavement

,c = coefficient of thermal expansion, inches/inch

Values of T should be determined by a test on a pavement in the vicinity of the proposed prestressed

concrete pavement; however, without other data, a value of 1 to 3 degrees per inch of pavement has

been found to be fairly representative of the maximum temperature gradient.

7. PRESTRESSING TENDON DESIGN.

a. General. The size and spacing of prestressing tendons required will be a function of the required

prestress level and the various losses that will occur in the steel tendons during and following

construction.

b. Size and Spacing on Tendons. The tendon stress losses occur as a result of elastic shortening

and creep of the concrete, concrete shrinkage, tendon relaxation, and slippage in the anchorage system.

The determination of these tendon losses is complex because of the many variables, some of which are

unknown without extensive field testing. From the experience gained in the few test and demonstration

sections and actual pavement sections, the tendon losses can be approximated as 20 percent of the

tendon stress needed to achieve the design prestress level in the concrete. With this approximation, the

total area of tendon steel required to accomplish the prestress level in the concrete after allowance for

tendon losses can be determined by

(16-5)

F

where

Ac = cross-sectional area of concrete being prestressed, square inches

fF = ultimate strength of the tendon steel, psi

The equation above is applicable to the determination of As based upon a recommended maximum

anchorage stress equal to seven-tenths of the ultimate strength of the tendon steel. If the steel is

anchored at a stress other than seven-tenths of the ultimate strength, the equation above must be

modified accordingly. With the total required As determined, the number and size of prestressing

16-4

Previous Page

Previous Page