UFC 3-260-02

30 June 2001

CHAPTER 14

FIBROUS CONCRETE PAVEMENT DESIGN

1. BASIS OF DESIGN. The design of fibrous concrete pavement is based upon limiting the ratio of

the concrete flexural strength and the maximum tensile stress at the joint, with the load either parallel or

normal to the edge of the slab, to a value found to give satisfactory performance in full-scale accelerated

test tracks. Because of the increased flexural strength of the fibrous concrete and the bridging of fibers

across cracks that develop in the concrete, the thickness can be significantly reduced; however, this

results in a more flexible structure, which causes an increase in vertical deflections and potential for

densification and/or shear failures in the foundation, pumping of the subgrade material, and joint

deterioration. To protect against these latter factors, a limiting vertical deflection criterion has been

applied to the thickness developed from the tensile stress criteria.

2. USES FOR FIBROUS CONCRETE. Although several types of fiber have been studied for concrete

reinforcement, most of the experience has been with steel fibers, and the design criteria presented

herein are limited to steel fibrous concrete. Fibrous concrete is a relatively new material for pavement

construction and lacks a long-time performance history. Experience indicates that with time and number

of passes logged on a fibrous concrete pavement, the fiber becomes exposed at the wearing surface

and becomes an FOD problem. Because of this, its use will require approval of the Headquarters,

U.S. Army Corps of Engineers (HQUSACE) (CEMP), HQ Air Force Command, or the Naval Facilities

Engineering Command. The major uses to date have been for thin resurfacing or strengthening overlays

where grade problems restrict the thickness of overlay that can be used. The use of fibrous concrete

pavement should be based upon the economics involved. Fibrous concrete will not be used in Navy

pavements.

3.

MIX PROPORTIONING CONSIDERATIONS.

a. The design mix proportioning of fibrous concrete will be determined by a laboratory study.

Typical mix proportions are shown on Table 14-1. The following are offered as guides and to establish

limits where necessary for the use of the design criteria included herein. Additional details may be found

in TM 5-822-7/AFM 88-6, Chapter 8.

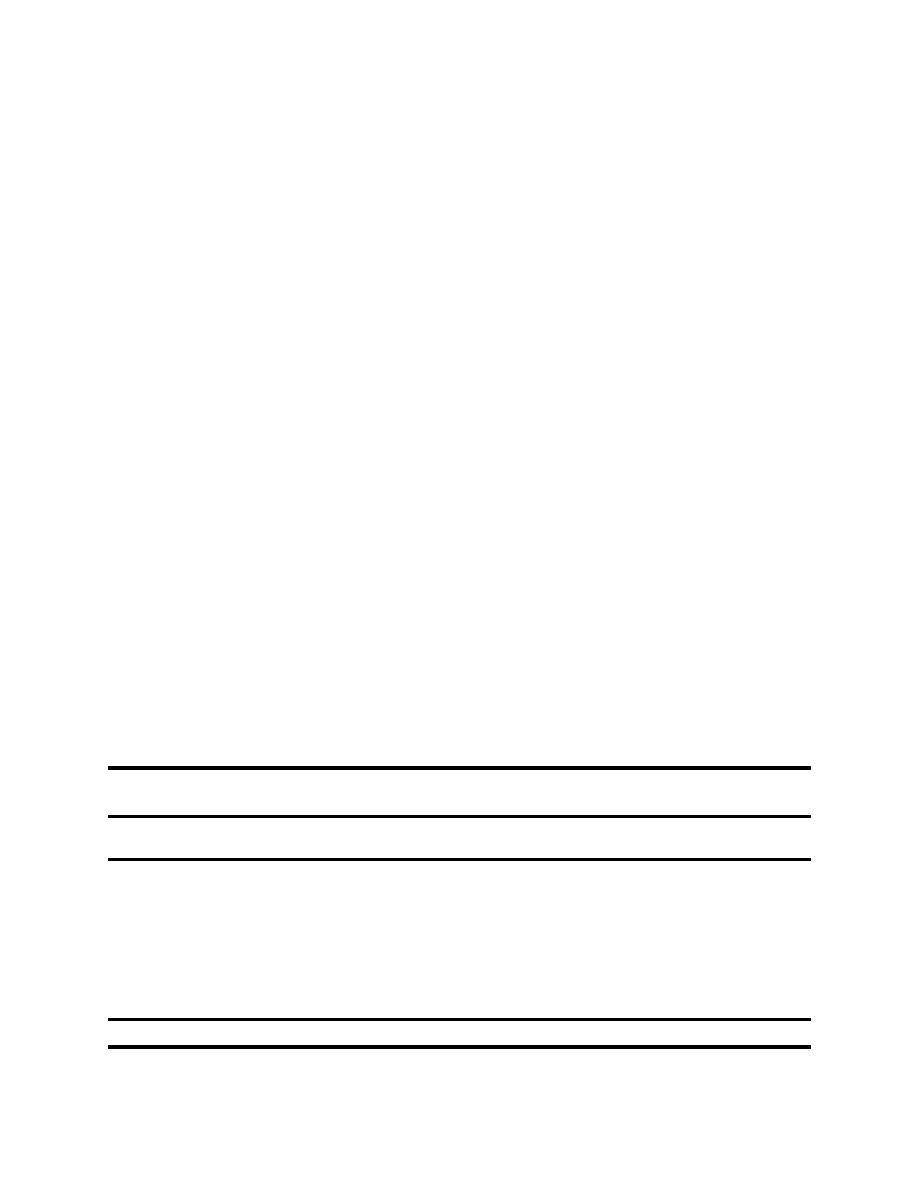

Table 14-1

Range of Proportions for Normal-Weight Fibrous Concrete1

9.5-mm (3/8-in.) Maximum

19-mm (3/4-in.) Maximum

Sized Aggregate

Sized Aggregate

Cement kg/m3 (lb/yd3)

355-590 (600-1,000)

295-535 (500-900)

Water-cement ratio

0.35-0.45

0.40-0.50

Percent of fine to coarse aggregate

45-60

45-55

Entrained air content (percent)

4-7

4-6

Fiber content (volume percent)

Deformed steel fiber

0.4-0.9

0.3-0.8

Smooth steel fiber

0.9-1.8

0.8-1.6

1

From ACI 544.1R-82, used with permission of the American Concrete Institute.

14-1

Previous Page

Previous Page