UFC 3-260-02

30 June 2001

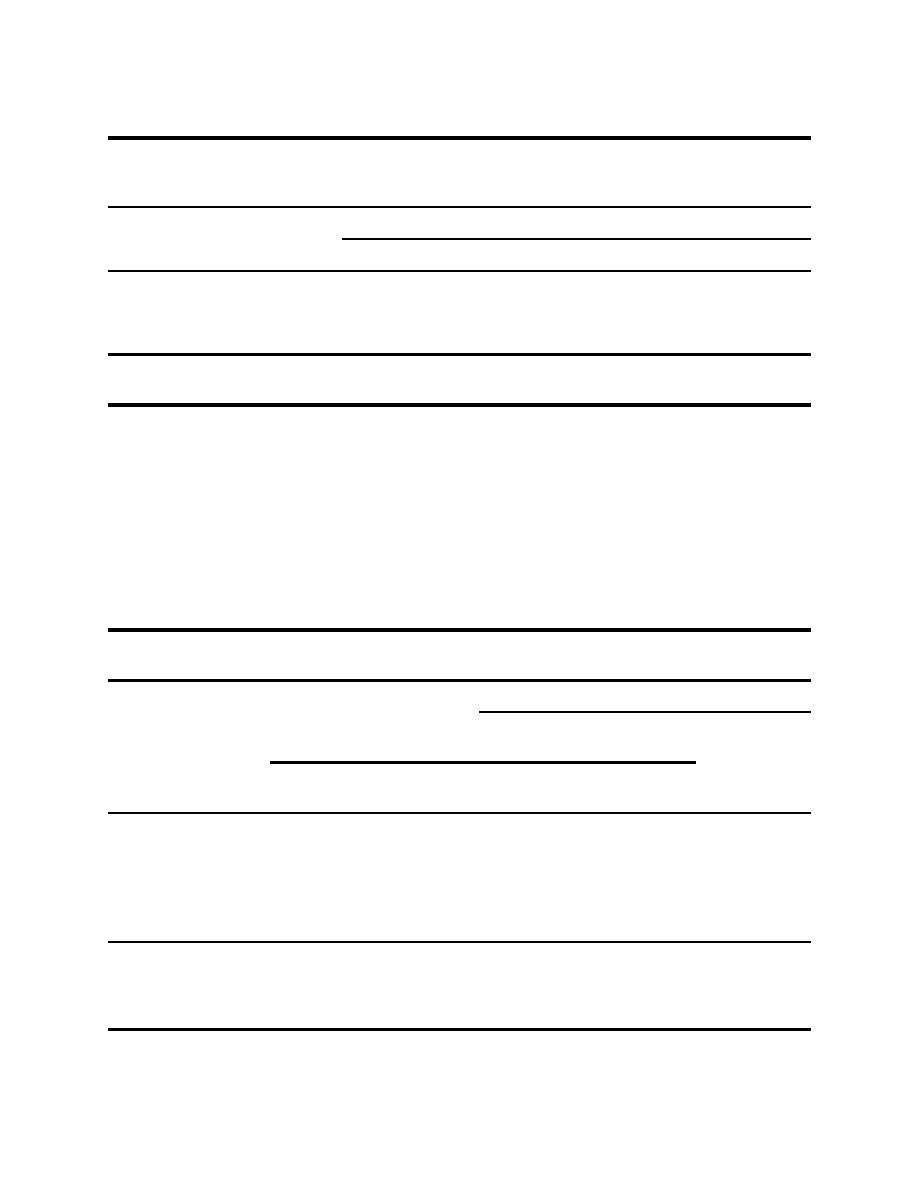

Table 7-1

Minimum Unconfined Compressive Strength for Cement, Lime, Lime-Cement, and Lime-

Cement-Fly Ash Stabilized Soils

Minimum Unconfined Compressive Strength, psi1

Flexible Pavement

Rigid Pavement

Stabilized Soil Layer

Base course

750

500

Subbase course, select material

250

200

or subgrade

1

Unconfined compressive strength determined at 7 days for cement stabilization and 28 days for lime,

lime fly ash, or lime-cement-fly ash stabilization.

are usually made on soaked remolded samples; however, where existing similar construction is

available, CBR tests should be made in-place on material when it has attained its maximum expected

water content or on undisturbed soaked samples. The procedures for selecting test values described for

subgrades apply to select materials and subbases. Experience has shown that CBR tests on gravelly

materials in the laboratory have tended to give CBR values higher than those obtained in tests in the

field. The difference is attributed to the processing necessary to test the sample in the 152-millimeter

(6-inch) mold, and to the confining effect of the mold. Therefore, the CBR test is supplemented by

gradation and Atterberg limits requirements for subbases, as shown in Table 7-2. Suggested limits for

select materials are also indicated. In addition to these requirements, the laboratory CBR must be equal

to or higher than the CBR assigned to the material for design purposes.

Table 7-2

Gradation and Atterberg Limit Requirements for Subbases and Select Materials

Maximum Permissible Value1

Gradation Requirements

Maximum1

Percent Passing

Design

2.0 mm

.075 mm

Material

CBR

Size, mm (in.)

(No. 10)

(No. 200)

LL

PI

Subbase

50

75 (3)

50

15

25

5

Subbase

40

75 (3)

80

15

25

5

Subbase

30

75 (3)

100

15

25

5

75 (3)2

252

352

122

Select material

20

--

Note:

LL signifies liquid limit; PI signifies plasticity index.

1

EI 02C202/AFJMAN 32-1016 contains maximum values for open graded and rapid draining

materials.

2

Suggested limits.

7-2

Previous Page

Previous Page