UFC 3-260-02

30 June 2001

subgrade in frost areas will not be considered part of the layered system of the airfield, which should be

comprised of only the wearing, base, and subbase courses.

(g) Base Course and Filter Layer. Relative thicknesses of the base course and filter

layer vary, and should be based on the required cover and economic considerations.

(h) Alternate Design. The reduced subgrade strength design provides a soil thickness

above a frost-susceptible subgrade which minimizes frost heave. For a more economical design, a frost-

susceptible select material or subbase may be used as a part of the total thickness above the frost-

susceptible subgrade. However, thickness above the select material or subbase must be determined by

using the FASSI of the select or subbase material. Frost-susceptible soils used as select materials or

subbases must meet current specifications; the restriction on the allowable percent finer than 0.02 mm is

waived.

(4) Surface Course. Materials requirements for construction of aggregate surfaced airfields

depend upon whether frost is a factor in the design.

(a) Nonfrost Areas. Material used for airfields should be sufficiently cohesive to resist

abrasive action. It should have a liquid limit no greater than 35 and a plasticity index between 4 and 9. It

also should be graded for maximum density and minimum volume of voids to enhance optimum moisture

retention while resisting excessive water intrusion. Gradation should consist of an optimal combination

of coarse and fine aggregates to ensure minimum void ratios and maximum density. This material will

exhibit cohesive strength as well as intergranular shear strength. Recommended gradations are shown

in Table 3-6. If the fines fraction of the material does not meet plasticity characteristics, the material may

be modified by adding chemicals. Chloride products can, in some cases, enhance moisture retention,

and lime can be used to reduce excessive plasticity.

(b) Frost Areas. Where frost is a consideration, a layered system should be used. The

percentage of fines should be restricted in all the layers to facilitate drainage and reduce the loss of

stability and strength during thaw periods. Use gradation numbers 3 and 4 shown in Table 3-6 with

caution, since they may be unstable in a freeze-thaw environment.

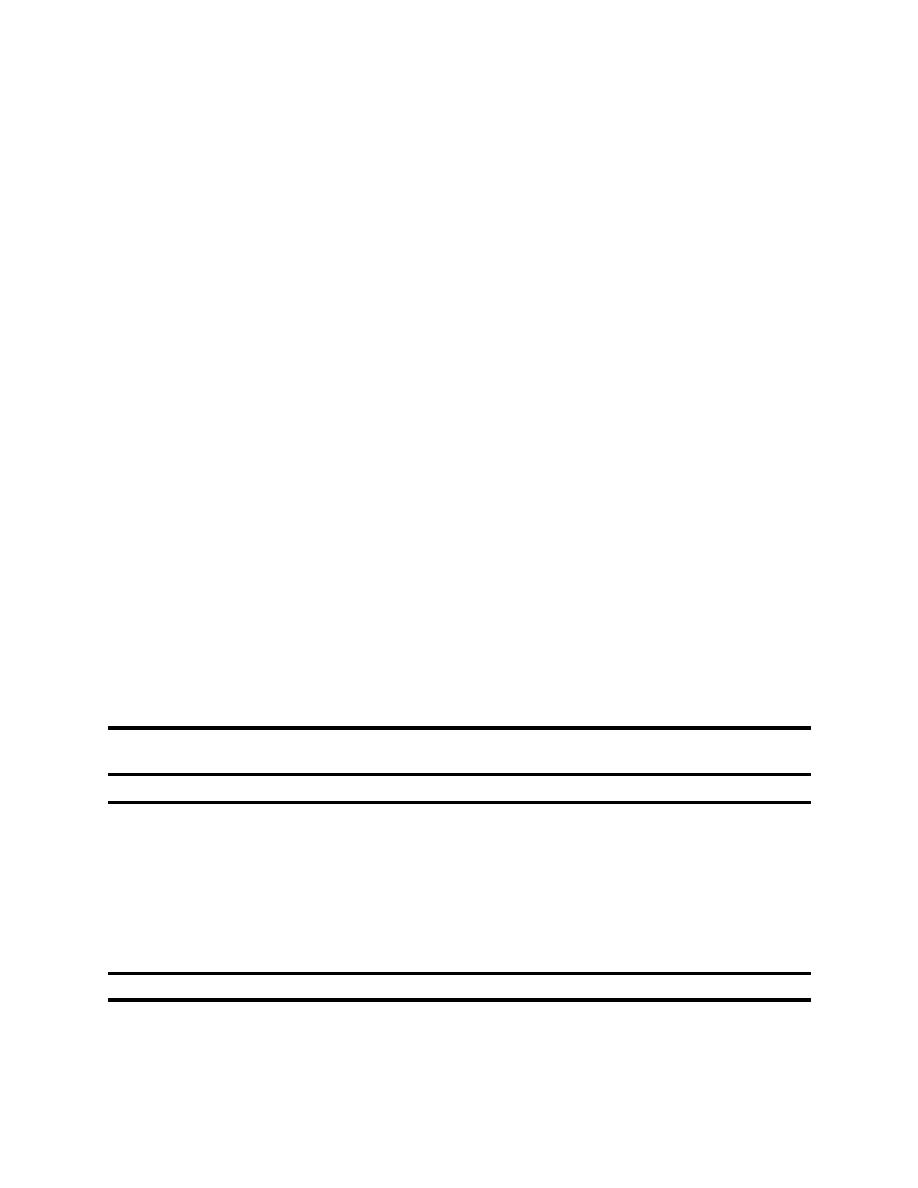

Table 3-6

Gradation for Aggregate Surface Courses (Percent Passing)

Sieve Designation

No. 1

No. 2

No. 3

No.4

25.0 mm (1")

100

100

100

100

9.5 mm (3/8")

50-85

60-100

--

--

No. 4

35-65

50-85

55-100

70-100

No. 10

25.50

40.70

40-100

55-100

No. 40

15.30

24-45

20-50

30-70

No. 200

8-15

8-15

8-15

8-15

Note: The percent by weight finer than 0.02 mm (0.04 in.) shall not exceed 3 percent.

3-10

Previous Page

Previous Page