2. STRESSES IN FLEXIBLE PAVEMENTS.

a. Single Wheels. Distribution of vertical stresses under a surface load

has a bell-shaped pattern. Stresses are at a minimum directly beneath the

wheel, and decrease with increasing depth. See NAVFAC DM-7 and NAVFAC DM-21

for stress distribution in soils.

b. Dual Wheels. When dual wheels support the same total load as a single

wheel, pavement stresses are reduced. At shallow depth, stresses are caused

principally by individual wheels acting singly, and are at a maximum beneath

the center of each wheel. At greater depths, stresses are at a maximum midway

between wheels, and approximate the stress caused by a single wheel supporting

the total load. Thus stresses in pavement are determined principally by

individual wheel loads, and especially by tire pressure, whereas required

total thickness of pavement, base, and subbase are determined principally by

total load.

c. Stress Repetition. The effects of stress repetition arc considered in

the design procedures by the concepts of equivalent 18 kip axle loads and the

DI. Although flexible pavements may sustain limited applications of a heavy

load, they may distort or fail under a high number of repetitions of the same

load.

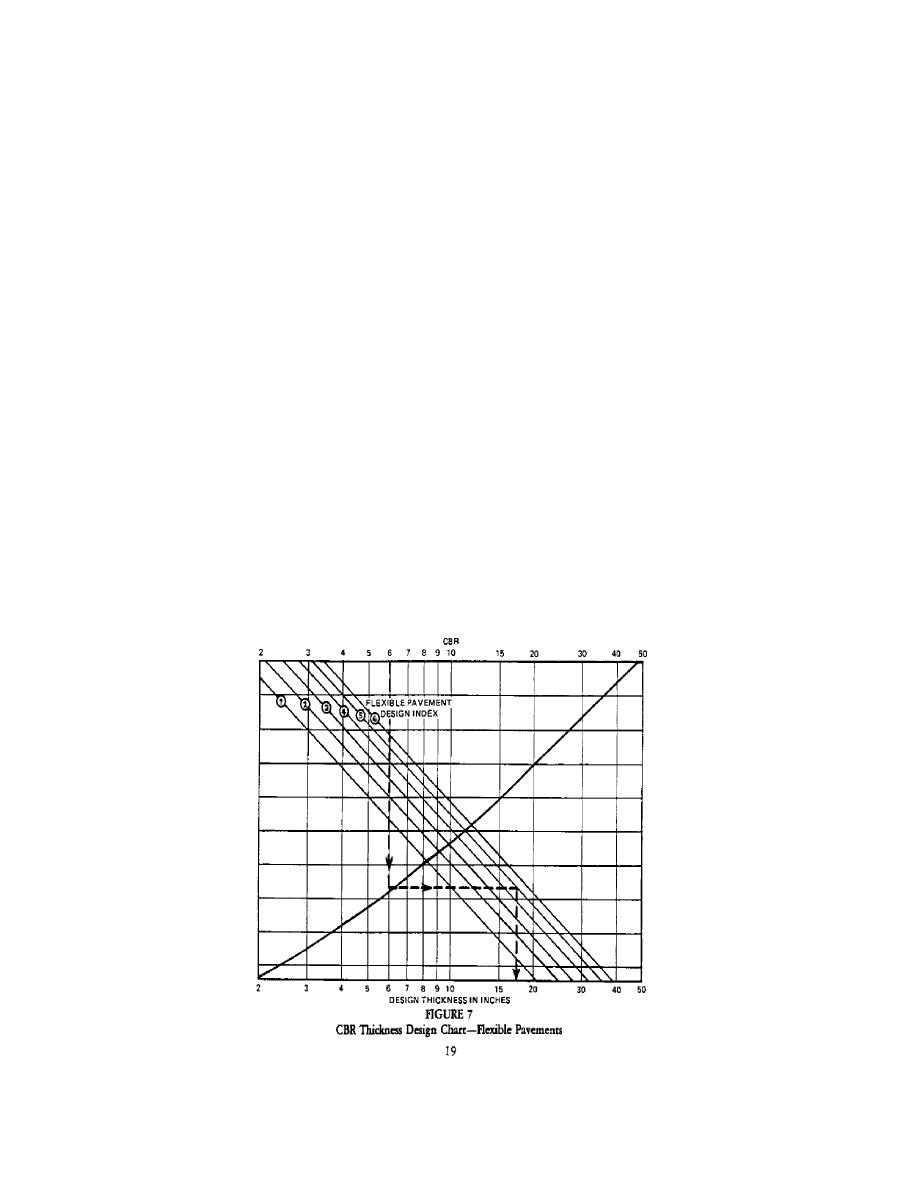

3. THICKNESS DESIGN PROCEDURES. Use the following procedures for the design of

flexible pavements:

a. Design Index. Determine the DI using the procedures of Section 3.

b. Subgrade CBR. From Section 4, determine the design subgrade CBR.

c. Total Thickness. Determine the total thickness of pavement required from

the design curve, Figure 7. Enter the design curve with the subgrade CBR,

proceed vertically to the ''break line," then horizontally to the DI, and

vertically to the design thickness.

Previous Page

Previous Page