TM 5-822-14/AFJMAN 32-1019

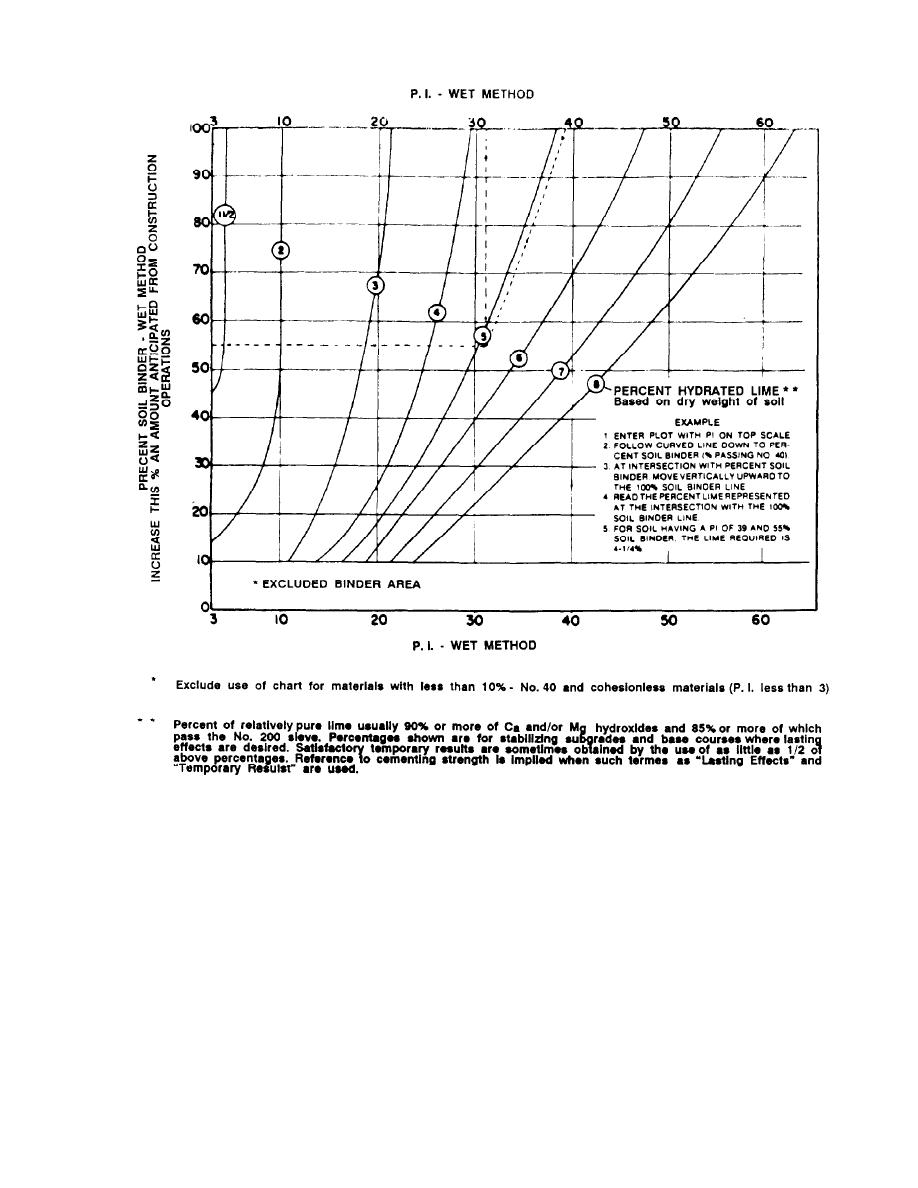

Figure 3-1. Chart for the initial determination of lime content.

curing at 120 degrees F for 48 hours has also been

(5) Step 5. Compare the results of the uncon-

found to give satisfactory results; however, check

fined compressive strength and durability tests

tests at 73 degrees for 28 days should also be

with the requirements shown in tables 2-2 and

conducted. Research has indicated that if acceler-

2-3. The lowest lime content which meets the

ated curing temperatures are too high, the pozzola-

unconfined compressive strength requirement and

nic compounds formed during laboratory curing

demonstrates the required durability is the design

could differ substantially from those that would

lime content. The treated material also must meet

develop in the field.

frost susceptibility requirements as indicated in

(4) Step 4. Test three specimens using the

the appropriate pavement design manuals. If the

unconfined compression test. If frost design is a

mixture should meet the durability requirements

consideration, test three specimens to 12 cycles of

but not the strength requirements, it is considered

freeze-thaw durability tests (ASTM D 560) except

to be a modified soil. If results of the specimens

wire brushing is omitted. The frost susceptibility

tested do not meet both the strength and durabil-

of the treated material should be determined as

ity requirements, a higher lime content may be

indicated in appropriate design manuals.

selected and steps 1 through 5 repeated.

3-4

Previous Page

Previous Page