TM

5-822-14/AFJMAN

32-1019

PERCENT BY WEIGHT, FINES

(MATERAIL PASSING NO. 200 SIEVE)

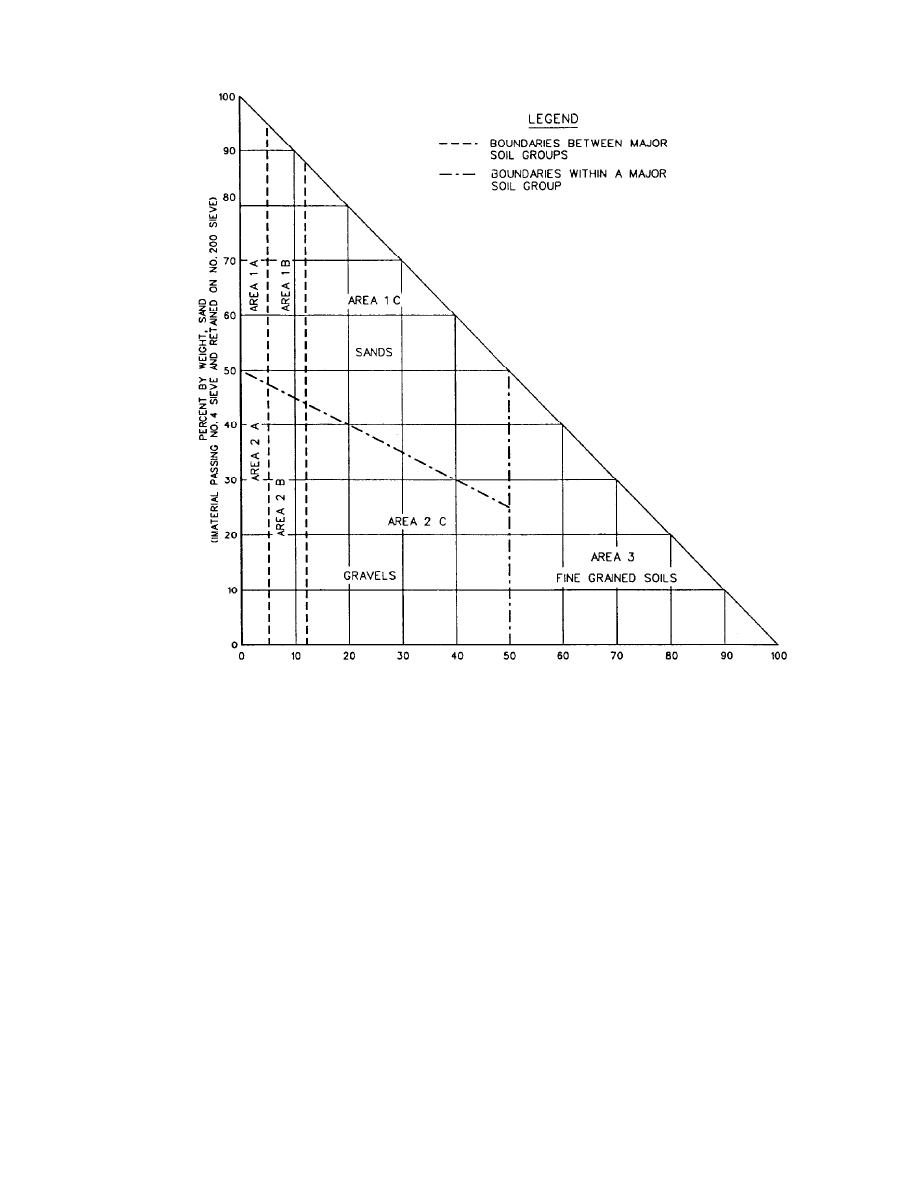

Figure 2-1.

Gradation triangle for aid in selecting a commercial stabilizing agent.

b. Limitations. In frost areas, stabilized soil is

lization indicate that the PI must not exceed 25,

only used in one of the upper elements of a

thus LCF is also a candidate stabilizing material.

pavement system if cost is justified by the reduced

At this point, the designer must make the final

pavement thickness. Treatment with a lower de-

selection based on other factors such as availabil-

gree of additive than that indicated for stabiliza-

ity of material, economics, etc. Once the type of

tion (i.e., soil modification) should be used in frost

stabilizing agent to be used is determined, samples

areas only with caution and after intensive tests,

must be prepared and tested in the laboratory to

because weakly cemented material usually has

develop a design mix meeting minimum engineer-

less capacity to endure repeated freezing and

ing criteria for field stabilization.

thawing than has firmly cemented material. A

2-2. Use of stabilized soils in Frost Areas.

possible exception is modification of a soil that will

a. Frost considerations. While bituminous, port-

be encapsulated within an impervious envelope as

land cement, lime, and LCF stabilization are the

part of a membrane-encapsulated-soil-layer pave-

most common additives other stabilizers may be

ment system. A soil that is unsuitable for encapsu-

used for pavement construction in areas of frost

lation due to excessive moisture migration and

design but only with approval obtained from the

thaw weakening may be made suitable for such

use by moderate amounts of a stabilizing additive.

HQUSACE (CEMP-ET), Washington, DC 20314-

Materials that are modified should also be tested

1000 or the appropriate Air Force Major Com-

to ascertain that the desired improvement is dura-

mand.

2-2

Previous Page

Previous Page