TM 5-822-10/AFM 88-6, Chap. 6

APPENDIX B

EXAMPLES OF COLD-MIX AND HOT-MIX RECYCLING PROGRAMS

B-1. Cold-mix recycling problem.

The middle 50 feet of an airfield taxiway is to be removed to a full depth (3 to 5 inches), replaced with a recycled cold

mix, and overlaid with 3 inches of new hot mix. The design mix must be developed for the recycled cold mix.

a. Step 1. Obtain samples of the in-place pavement (use jackhammer or other acceptable means).

b. Step 2. Run an extraction on the old asphaltic pavement to determine the following:

(1) Asphalt content. Use the determination of the existing asphalt content as a guide to calculate how much, if

any, additional asphalt binder will be needed.

(2) Asphalt penetration. Perform a penetration test to determine if the existing asphalt has become so brittle that

it needs rejuvenating. If possible, avoid using a rejuvenator with recycled cold mixes. Until the rejuvenator penetrates the

old asphalt, the mix is unstable and could remain unstable for as long as 2 months. Generally, a slow-set asphalt emulsion

is preferred for cold-mix recycling.

c. Step 3. Prepare a set of samples varying the amounts of asphalt emulsion added, and compact at 75-blow

compaction effort at a temperature of 250 degrees F. Vary the amount of asphalt emulsion added from 0 to 2.5 percent

in 0.5 percent increments. This range will generally be large enough to bracket the optimum amount of emulsion to be

added.

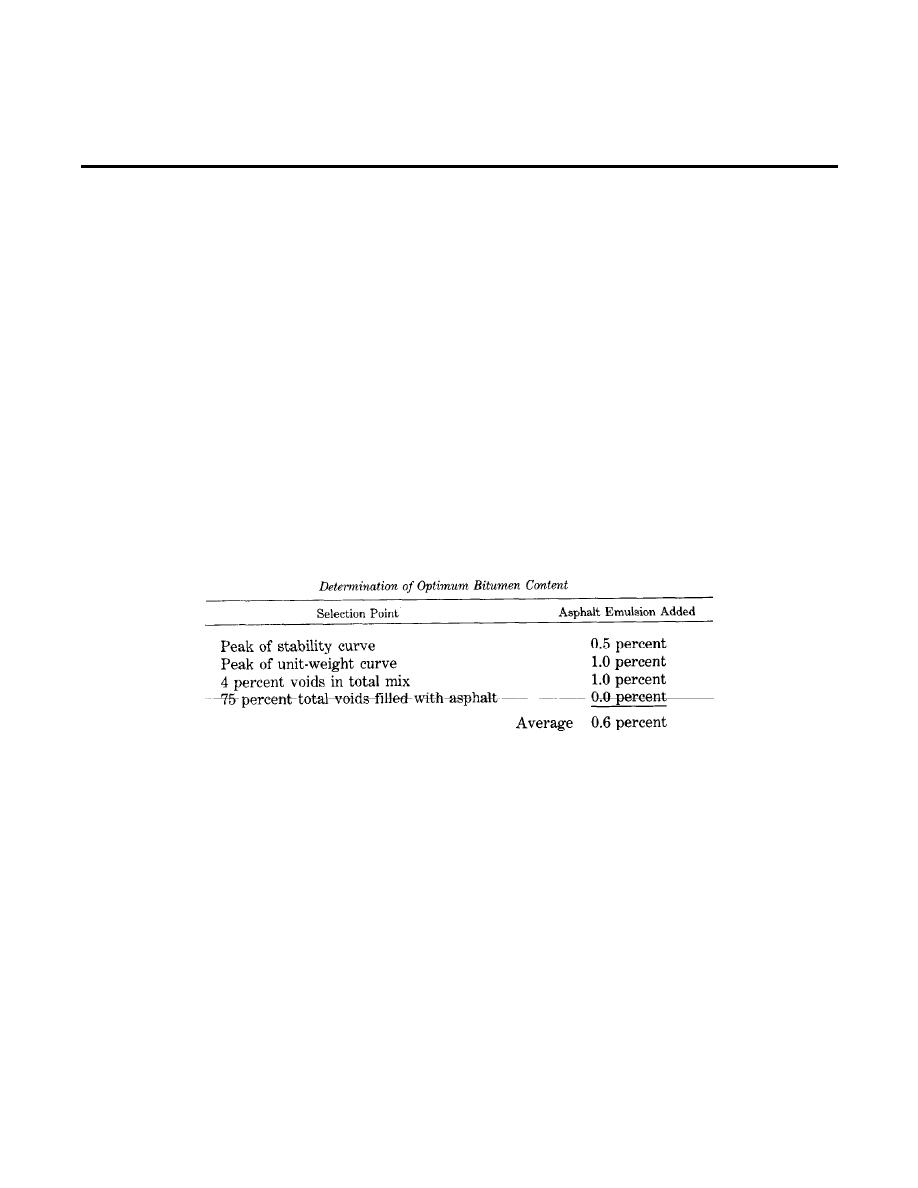

d. Step 4. Test the samples obtained in step 3 for stability, flow, unit weight, percent voids total mix, and percent

voids filled with asphalt. Record the test results in plots similar to those shown in figure B-1. The plots in figure B-1 are

used to determine the optimum asphalt emulsion to be added.

e. Step 5. Using figure B-1 and the procedure outlined in TM 5-822-8/AFM 88-6, chap 9, and TM 5-825-2/AFM

88-6, chap 2, select the preliminary optimum asphalt emulsion to be added as follows:

f. Step 6. Determine the optimum water content by preparing a set of samples of various water contents (0.6 percent

added asphalt emulsion held constant) using the 75-blow compaction effort at the approximate temperature at which the

reclaimed asphalt concrete will be during construction.

g. Step 7. Using the data obtained in step 6, plot the dry density versus the water content, as shown in figure B-2.

Pick the peak of the curve to obtain the optimum water content. For the example, the optimum water content is 2 percent.

h. Step 8. Adjust mix during laydown operations as needed.

B-1

Previous Page

Previous Page