TM 5-822-10/AFM 88-6, Chap. 6

CHAPTER 5

RECYCLING OF PORTLAND CEMENT CONCRETE

5-1.

General.

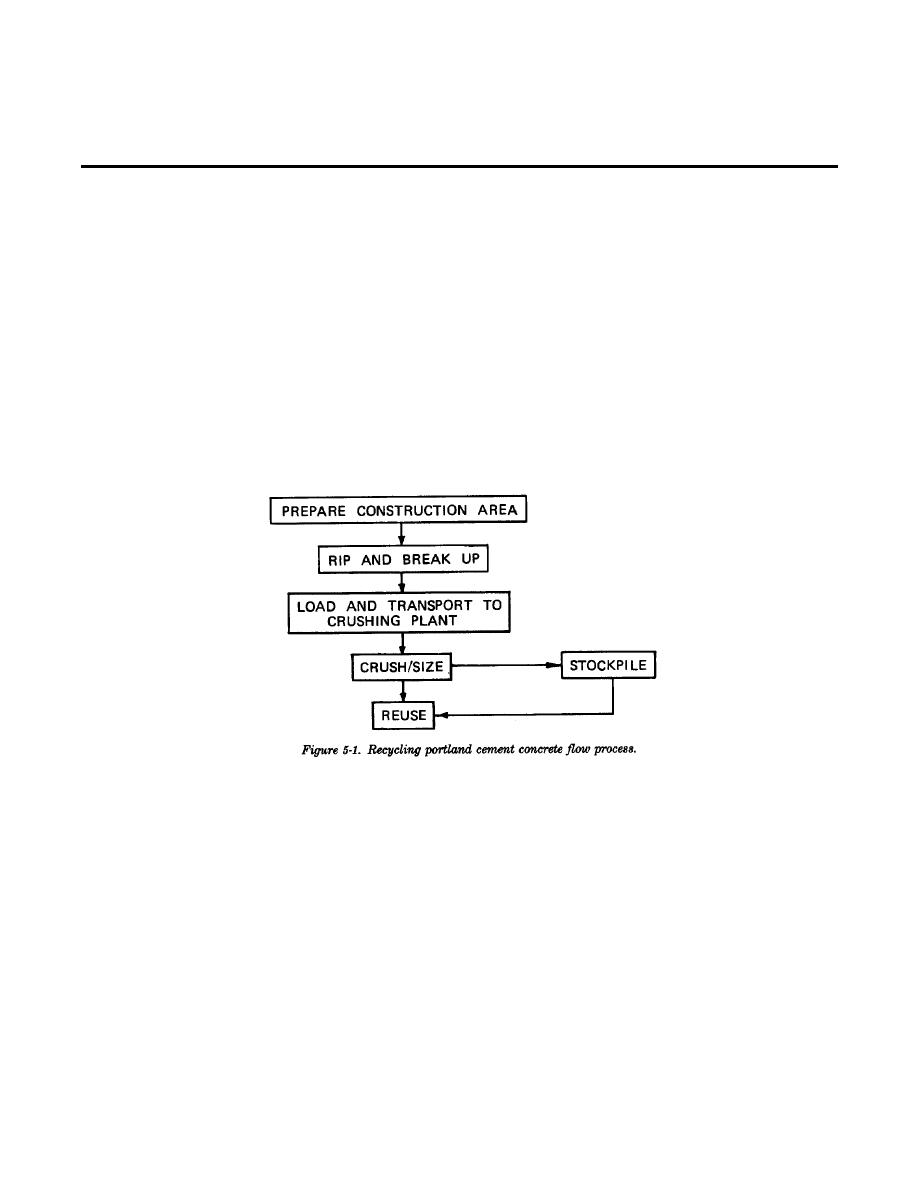

This chapter provides information and instruction for the preparation of contract specifications and construction

operations involving the recycling of portland cement concrete as aggregates in road and airfield pavements. As shown

in figure 1-2, portland cement concrete recycling or other methods may correct many types of pavement distress.

5-2.

Recycling portland cement concrete procedure.

Existing portland cement concrete when removed as unwanted pavements and structural elements is usually wasted

and disposed of outside the project limits. However, the contractor may be given the option of recycling these materials

as construction aggregates for portland cement concrete pavement (PCCP), Econocrete, cement- treated base (CTB), and

aggregate base (AB). The basic process is shown in the flow chart of figure 5-1. The first step involves preparing the

existing pavement or other structural elements for fracturing into pieces of manageable size for the available equipment.

The pavement is broken by fracturing with a pavement breaker, scarifying, ripping, or jackhammering. The broken

concrete is then hauled to the crushing plant where it is crushed and sized according to specification requirements. The

aggregates are then reused directly from the crushing plant or stockpiled for future use. Some of the advantages and

disadvantages of recycling portland cement concrete are given in table 1-1.

5-3.

Sources for recycled aggregates.

Aggregates can be produced from the breakup and crushing of existing portland cement concrete pavement and struc-

tural elements.

a. Pavement. where an asphalt concrete surface is present on an existing rigid pavement, the asphalt concrete must

be removed before the old portland cement concrete pavement is broken up. It is intended that all of the asphalt concrete

be removed; however, isolated areas of asphalt concrete up to 1 inch in thickness and small asphalt concrete patches will

be considered acceptable. The old portland cement concrete pavement should be removed in a manner that excludes

subbase and subgrade material to the maximum extent practicable.

b. Structures. It is the intention of this operation to produce the maximum amount of salvage portland cement

concrete that can be crushed, stockpiled, and accepted as aggregate in new portland cement concrete. All reinforcing steel

should be removed from the salvaged concrete either prior to or during the crushing operation.

5-4.

Excess recycled aggregates.

All excess recycled aggregate should be stockpiled for use on other Government projects. If the ownership of the

excess recycled aggregate is transferred to the contractor, credit should be given to the Government for its value.

5-1

Previous Page

Previous Page