UFC 3-250-03

15 May 2001

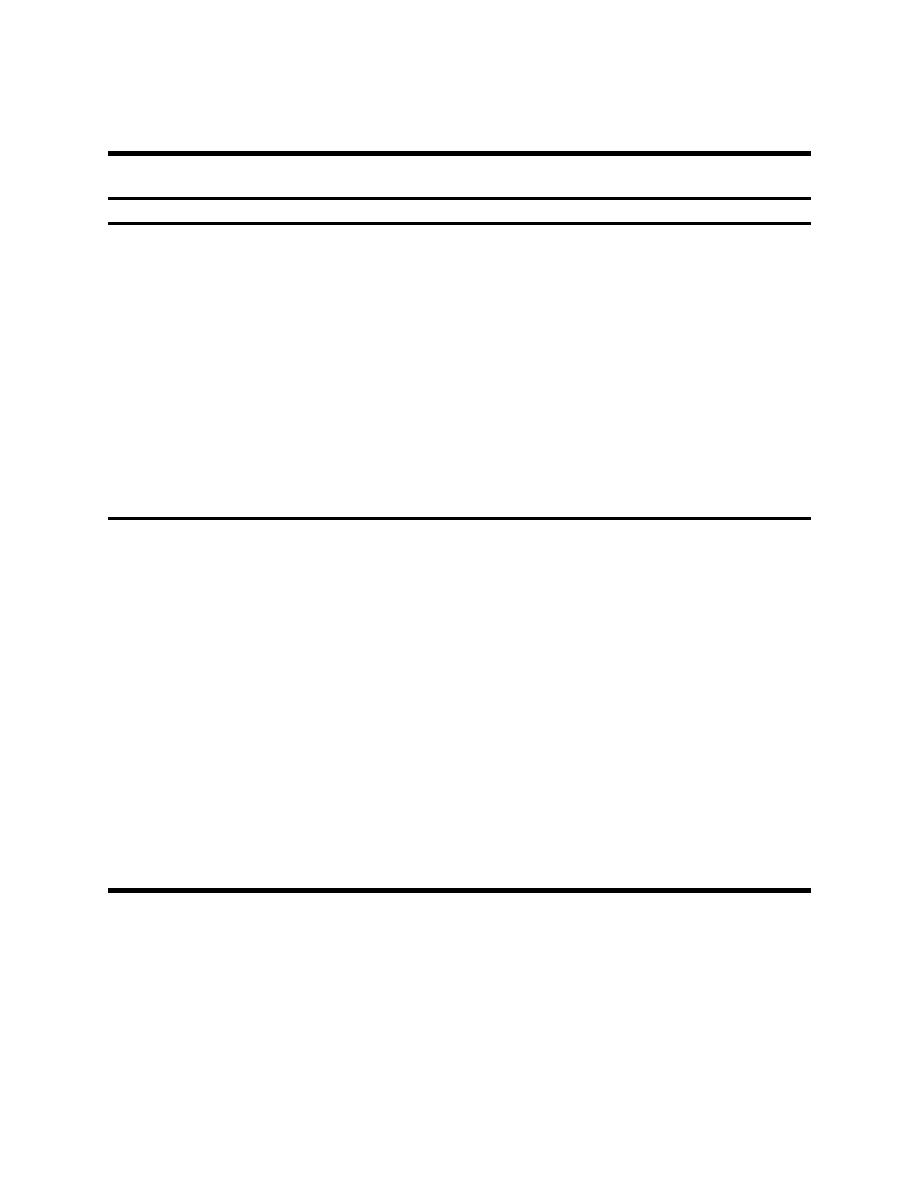

Table 2-14

Properties of Cellulose Fibers (After NAPA 1994)

Properties

Requirement

Sieve Analysis

Method A

Alpine Sieve1 Analysis

Fiber length

6 mm (0.25 in.) (max.)

Passing 150 Fm (No. 100) sieve

70% ( 10%)

Method B

Mesh Screen2 Analysis

Fiber length

6 mm (0.25 in.) (max.)

Passing 850 Fm (No. 20) sieve

85% ( 10%)

425 Fm (No. 40) sieve

65% ( 10%)

106 Fm (No. 140) sieve

30% ( 10%)

Ash Content3

18% ( 5%) non-volatiles

pH4

7.5 ( 1.0)

Oil Absorption5

5.0 ( 1.0) (times fiber weight)

Moisture Content6

< 5% (by weight)

1

Method A, Alpine Sieve Analysis. This test is performed using an Alpine air jet sieve (Type 200 LS). A

representative 5 gram sample of fiber is sieved for 14 minutes at a controlled vacuum of 75 kPa (11 psi).

The portion remaining on the screen is weighed.

2

Method B, Mesh Screen Analysis. This test is performed using standard 850, 425, 250, 180, 150, 106

Fm (No. 20, 40, 60, 80, 100, 140) sieves, nylon brushes, and a shaker. A representative 10 gram

sample of fiber is sieved using a shaker and two nylon brushes on each screen. The amount retained

on each sieve is weighed and the percentage passing calculated. Repeatability of this method is

suspect and needs to be verified.

3

Ash Content. A representative 2-3 gram sample of fiber is placed in a tared crucible and heated

between 595E and 650EC (1100E and 1200EF) for not less than 2 hours. The crucible and ash are

cooled in a desiccator and reweighed.

4

pH Test. Five grams of fiber is added to 100 ml of distilled water, stirred, and let sit for 30 minutes.

The pH is determined with a probe calibrated with pH 7.0 buffer.

5

Oil Absorption Test. Five grams of fiber is accurately weighed and suspended in an excess of mineral

spirits for not less than 5 minutes to ensure total saturation. It is then placed in a screen mesh strainer

(approximately 0.5 square millimeter hole size) and shaken on a wrist action shaker for 10 minutes

(approximately 1 1/4 inch motion at 240 shakes/minute). The shaken mass is then transferred without

touching, to a tared container and weighed. Results are reported as the amount (number of times its

own weight) the fibers are able to absorb.

Moisture Content. Ten grams of fiber is weighed and placed in a 121EC (250EF) forced air oven for

6

2 hours. The sample is then reweighed immediately upon removal from the oven.

2-35

Previous Page

Previous Page