UFC 3-250-03

15 May 2001

fiber) which forms a mastic portion of the SMA mixture. This mastic stabilizes the coarse aggregate and

reduces the final air voids in the SMA to about 3 to 4 percent. SMA is comparable to hot-mix asphalt in

regards to structural design, mix design, and construction. SMA originated in Europe and has recently

been placed by state and federal agencies on projects throughout the country. The design and

construction of SMA pavements are described in this appendix.

b. MATERIALS.

(1) Aggregates. The gradation used for SMA is gap-graded for the coarse aggregate retained

on the 4.75 millimeter (No. 4) sieve. This coarse aggregate will make up from 72 to 80 percent of the

aggregate in the mix. The coarse aggregate should be 100 percent passing the 19 millimeter (3/4-inch)

sieve. The amount of the fine material passing the 75 Fm (No. 200) sieve will be from 8 to 10 percent.

Table 2-12 lists the gradation as recommended by the FHWA. This gradation is based on the

recommendations of a technical working group that reviewed the performance of SMA mixtures in place.

Table 2-13 lists the recommended coarse and fine aggregate properties for SMA.

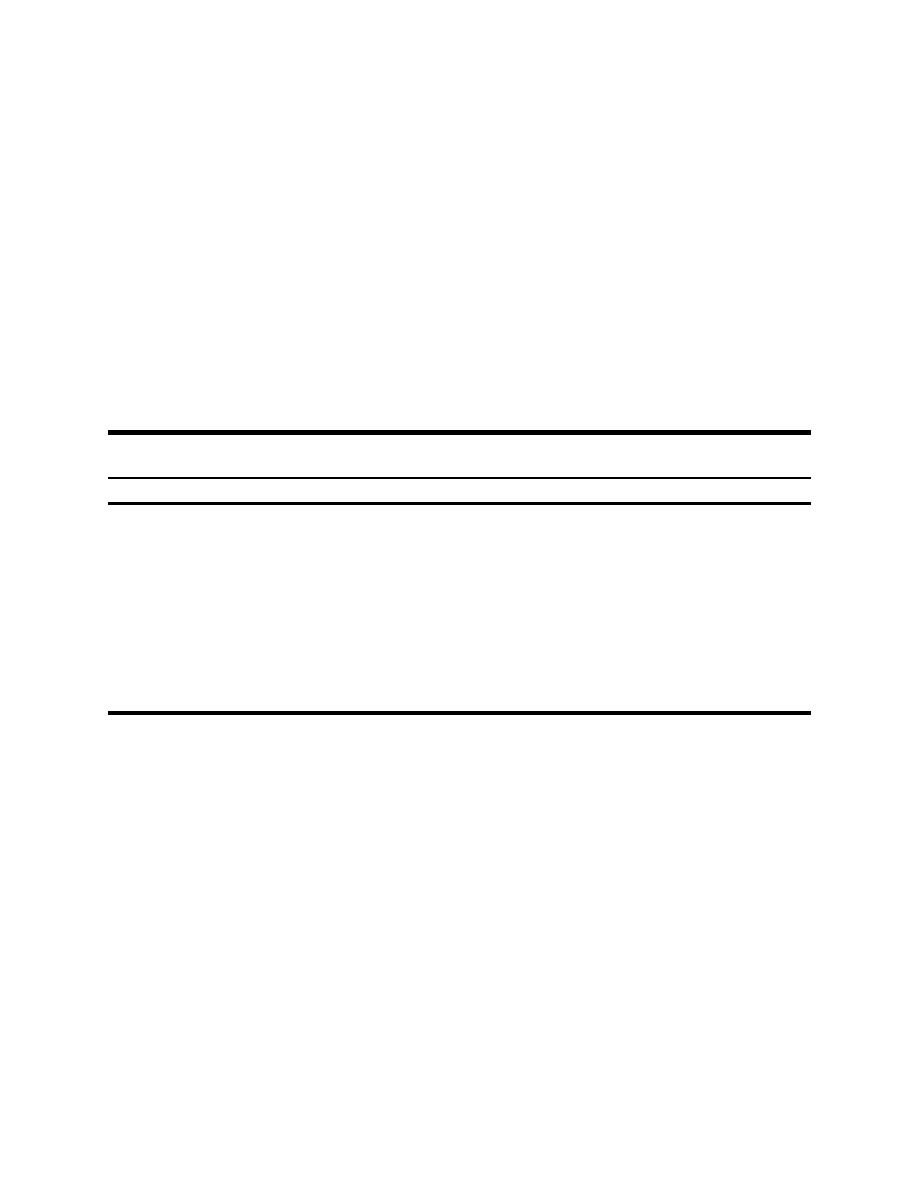

Table 2-12

SMA Gradation Guideline (After NAPA 1994)

Sieve Size

Percent Passing

19 mm (3/4 inch)

100

12.7 mm (1/2 inch)

85-95

9.5 mm (3/8 inch)

75 maximum

4.75 mm (No. 4)

20-28

2.36 mm (No. 8)

16-24

600 Fm (No. 30)

12-16

300 Fm (No. 50)

12-15

75 Fm (No. 200)

8-10

(2) Filler. As presented in table D1 for SMA mixtures, the recommended amount of aggregate

filler (dust) passing the 75 Fm (No. 200) sieve is 8 to 10 percent. This amount of filler in the SMA is

higher than that usually found in dense graded hot mix asphalt (HMA). The amount of filler is important

in terms of obtaining the desired mixture air voids and in affecting the optimum asphalt content. The

SMA asphalt content is sensitive to the aggregate fines and filler content. In Europe, SMA mixtures

commonly employ a filler-to-asphalt ratio of approximately 1.5. In contrast, conventional dense graded

hot mix in the United States typically recommend a filler-to-asphalt ratio of less than 1.2. A well-graded

filler with no more than 20 percent of the total filler smaller than 20 microns is required. Commercial

fillers are added by mineral filler feeder systems. Fly ash, limestone dust, and other types of rock dust

have been used successfully as fillers for SMA applications.

(3) Stabilizer.

(a) General. There is a tendency for the asphalt binder to drain from the aggregate during

storage, transportation, or placement because of the high asphalt content in the mix, the thick asphalt

coating on the coarse aggregate, and the high voids in the aggregate skeleton. In order to reduce this

drainage potential, stabilizers are used to stiffen the mastic or to increase the asphalt binder viscosity.

These stabilizers can be categorized into two groups: either (cellulose fibers or mineral fiber) or

2-33

Previous Page

Previous Page