UFC 3-240-13FN

25 May 2005

also serves to protect feedwater piping from corrosion. A sufficient amount of the

oxygen scavenger must be fed to meet the demand for the oxygen initially present and

provide an excess residual (reserve amount) for occasions when the oxygen level may

increase unexpectedly, so that water testing will always indicate that an excess amount

is present. (See Table 3-3 for typical sulfite levels in the boiler water.)

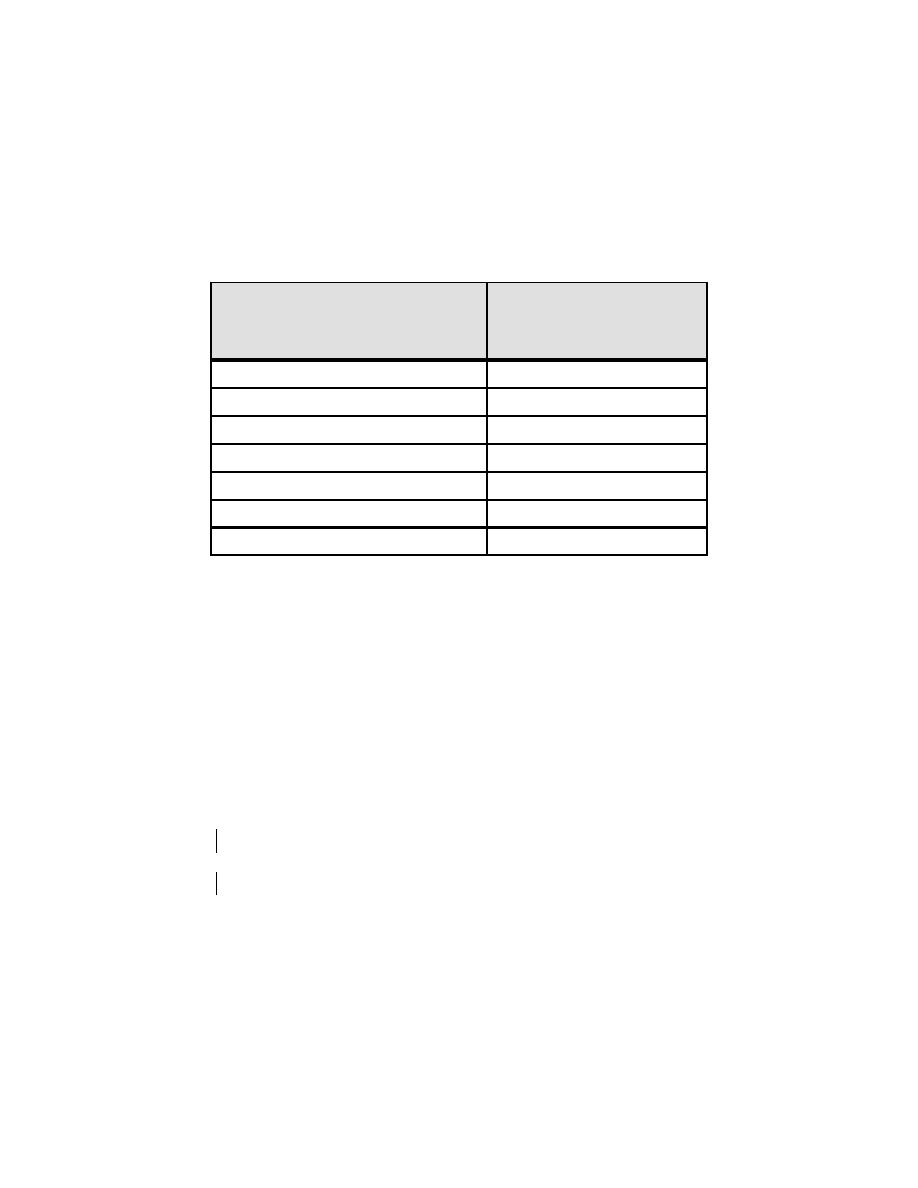

Table 3-3. Levels of Sulfite to be Carried in Boiler Water

Sulfite

Boiler Pressure

Residual

KPa (psig)

(as ppm SO3)

0-103 (0-15)

20-40

110-1020 (16-149)

20-40

1030-2060 (150-299)

20-40

2070-3100 (300-449)

20-40

3100-4130 (450-599)

20-40

4140-5160 (600-749)

15-30

> 5170 (> 750)

15-30

3-2.6.2.2

over 6205 kilopascals (900 pounds per square inch gauge), the list of oxygen

scavengers includes specialty volatile treatments such as hydroxylamine, hydroquinone,

carbohydrazide, hydrazine sulfate, and erythorbic acid. Hydrazine can no longer be

used because it is a suspected carcinogen. Like hydrazine, these specialty volatile

treatments not only scavenge oxygen but also passivate metal surfaces. These

chemicals are normally maintained in the boiler water in the parts-per-billion (ppb)

range. Sulfite-type oxygen scavengers are not used in boilers over 6205 kilopascals

(900 pounds per square inch gauge) because of the potential for thermal decomposition

producing sulfur dioxide and hydrogen sulfide, both of which can cause corrosion. The

thermal decomposition reactions are:

Na2SO3 + H20 + Heat → 2NaOH + SO2↑

EQUATION

(16)

4Na2SO3 + 2H2O + Heat → 3Na2SO4 + 2NaOH + H2S↑

EQUATION

(17)

These reactions have been shown to occur at boiler pressures as low as 4140

kilopascals (600 pounds per square inch gauge), although they do not usually create a

serious problem until pressures exceed 6205 kilopascals (900 pounds per square inch

gauge).

58

Previous Page

Previous Page