UFC 3-240-13FN

25 May 2005

3-1.3

Measuring Equipment. To develop an appropriate water treatment

program for a steam boiler system, as well as to monitor the effectiveness of the on-

going program, measure the quantities of steam, feedwater, blowdown, makeup, and

condensate into and from the system. As a minimum, install a flow meter in the makeup

water line. Installing flow meters on the feedwater line and in the steam header is also

advisable, but due to cost considerations this practice is usually limited to large steam

boilers. The rates and volumes for production of condensate and blowdown water can

be calculated using the method described in paragraphs 3-1.5 and 3-1.6.

3-1.4

Common Boiler Problems. Common water-related problems inside the

entire boiler system are corrosion, deposition, and carryover.

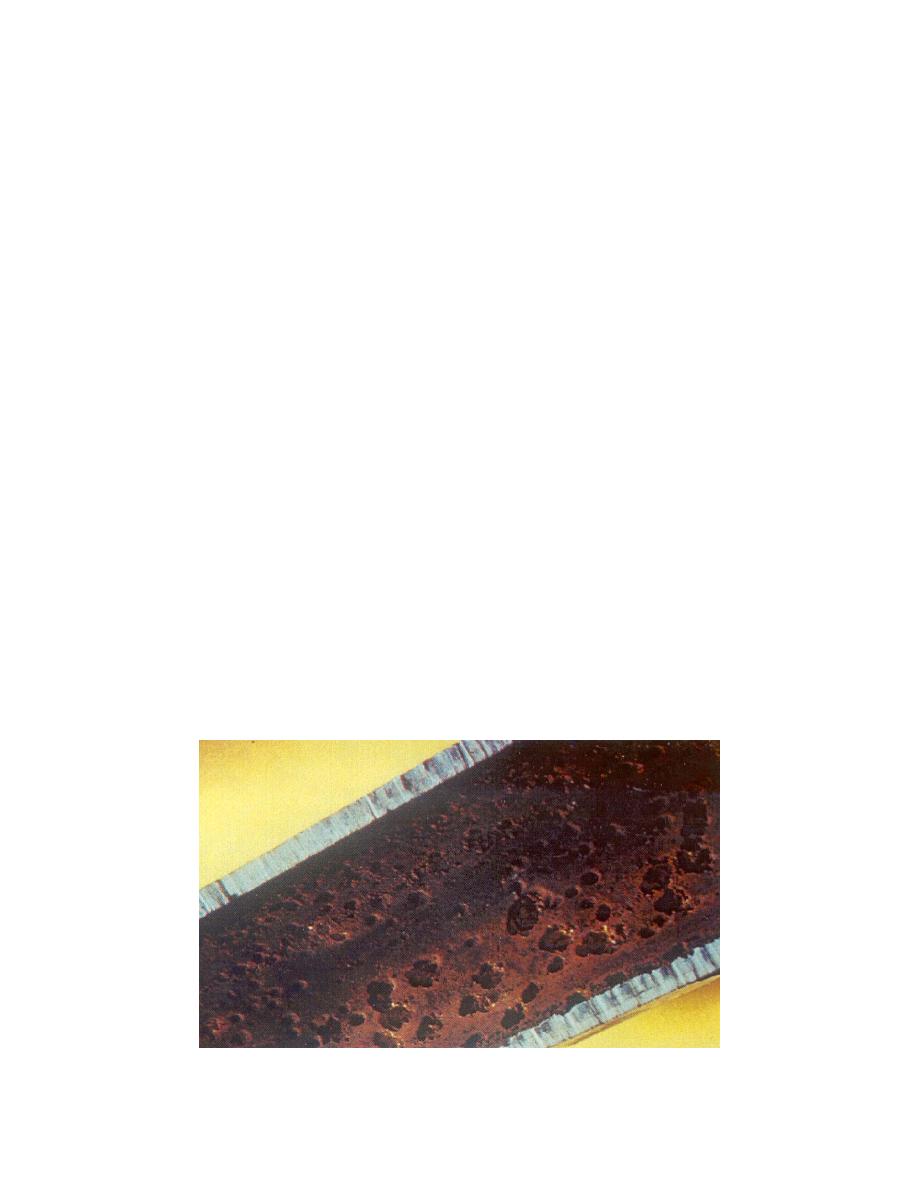

3-1.4.1

Corrosion Problems. Corrosion problems are the result of the action of

oxygen and the effect of low or high pH on metal components, including the boiler tubes

and drum, which are constructed of carbon steel. Corrosion can also occur from

excessive alkalinity of excessive pH of the boiler water. This caustic attack is most

likely to occur under scale or deposits, where very high local concentrations of

hydroxide can build or in zones where insufficient cooling flows fails to sufficiently

remove the heat input, leading to boiling, and thus steam blanketing occurs." Corrosion

can occur in the boiler, as well as in the pre-boiler and after-boiler sections, which can

also be constructed of carbon steel. Corrosion can result in loss of metal volume or in a

reduction of the integrity of the metal, situations that can lead to structural failure,

particularly when metal loss is localized (see Figure 3-4). Corrosion is therefore also a

safety concern. Corrosion in the steam lines, condensate lines located in the after-boiler

section, and in the carbon steel piping can result in the production of system leaks

leading to the loss of condensate, a situation which increases demands for energy,

water, and chemicals.

Figure 3-4. Boiler Tube Oxygen Pitting

38

Previous Page

Previous Page