UFC 3-240-13FN

25 May 2005

→

Hardness

Sodium

Sodium

Hardness

Zeolite

Chloride

Zeolite

Chloride

The completeness of the regeneration is dependent upon the strength of the

salt solution (brine) used and the length of time the solution is in contact with the resin.

After the resin is regenerated, it can be used again and again (after regeneration) to

continue to remove hardness from water. The following procedure is typical for an ion

exchange resin regeneration process.

2-2.5.1.2.1 Backwash. Before the exhausted resin bed is regenerated, it must be

backwashed by flowing water from bottom to top. The flow rate must be adequate to

remove any solids that have been caught on top of the bed. The resin bed volume will

also be expanded by about 50% due to the backwash flow; the volume of expansion will

be dependent upon the flow rate. The backwash flow rate should be controlled so that it

will not sweep ion exchange resin out of the softener to the waste collection area. A

backwash rate of 2.72 to 4.07 liters per second per square meter (4 to 6 gallons per

minute per square foot) of bed surface for about 10 minutes is normal, but the

manufacturer's recommendations should be followed.

2-2.5.1.2.2 Brining. Next comes the addition of salt, a process known as "brining." A

10% (by saturation) solution of sodium chloride salt brine is slowly added with a down-

flow rate of 1.11 to 2.22 liters per second per cubic meter (0.5 to 1 gallon per minute per

cubic foot) of bed volume for about 30 minutes. Rock salt is preferred to granulated salt

as a brining salt because it is equally as effective, less expensive, and less prone to

cake. Some installations may start with a solution of concentrated or saturated brine,

which must be diluted before use in the brining step. The salt required and the capacity

regenerated is shown for a typical resin in Table 2-3; however, the manufacturer's

instructions should be followed, if available.

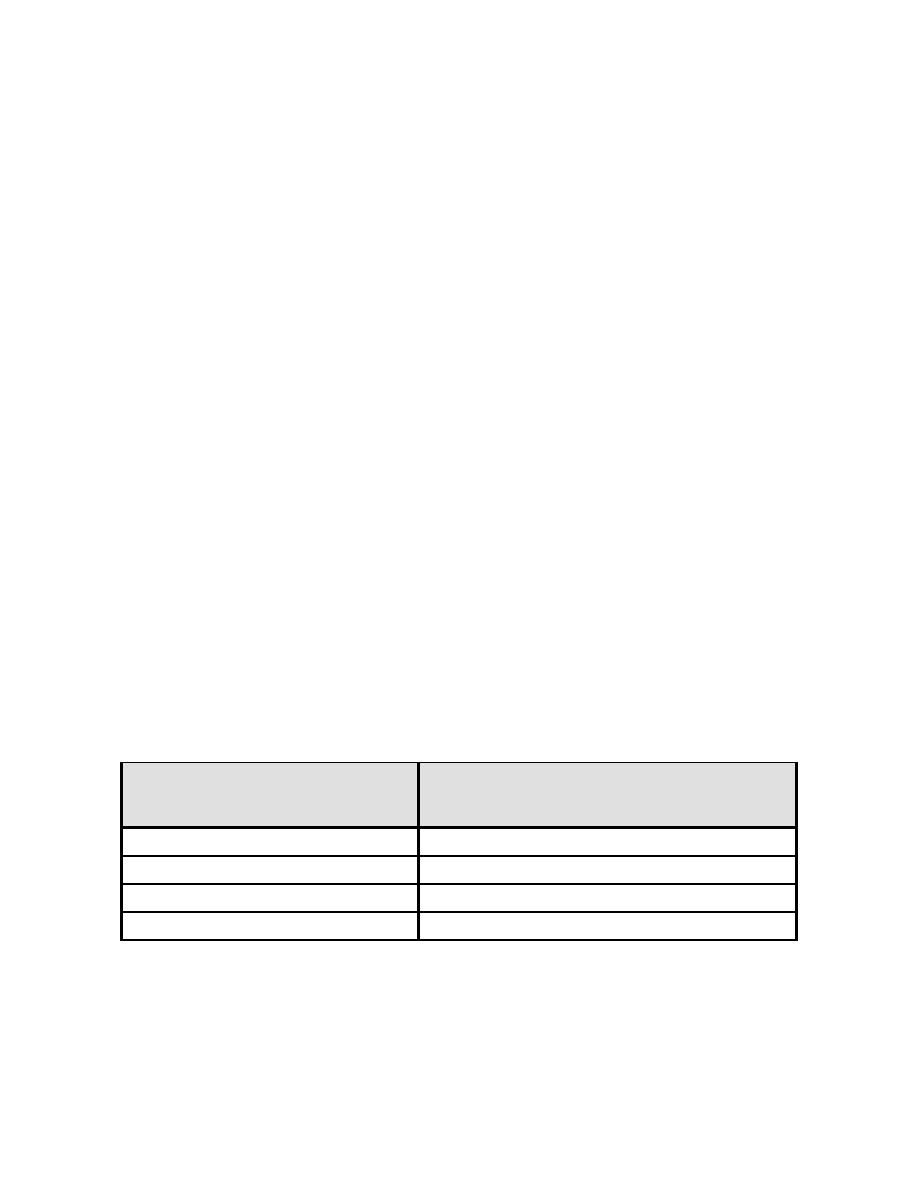

Table 2-3. Salt Required for Regeneration of a Commonly Used Cation Resin

Salt Use per liter of Ion Exchange

Capacity of Ion Exchange Material

Material

kg/m3 (lb/ft3)

80 (5.0)

43,450 (19,000)

120 (7.5)

55,130 (24,000)

160 (10.0)

61,615 (27,000)

240 (15.0)*

73,290 (32,000)*

* Practical upper limit for exchange capacity. This upper limit and the actual dose per capacity

relationship may vary with the resin; the manufacturer's instructions should be followed.

2-2.5.1.2.3 Slow Rinse. A slow rinse follows the brining step and is performed at the

same rate as the brining step. The rinse is performed with downflow through the

softener. One to 3 bed volumes of fresh water are used to remove most of the excess

20

Previous Page

Previous Page