UFC 3-240-13FN

25 May 2005

that is formed is allowed to settle for subsequent removal as a watery sludge. The

treated water is filtered prior to use as makeup.

2-2.4.2

Cold and Hot Processes. Adding lime and soda ash at ambient

temperature is referred to as the "cold lime-soda process." When lime and soda ash are

reacted with the water at temperatures greater than 100 oC (212 oF), the process is

called the "hot lime-soda process". The hot process removes a greater amount of the

hardness, alkalinity, and silica from the water than the cold process.

2-2.5

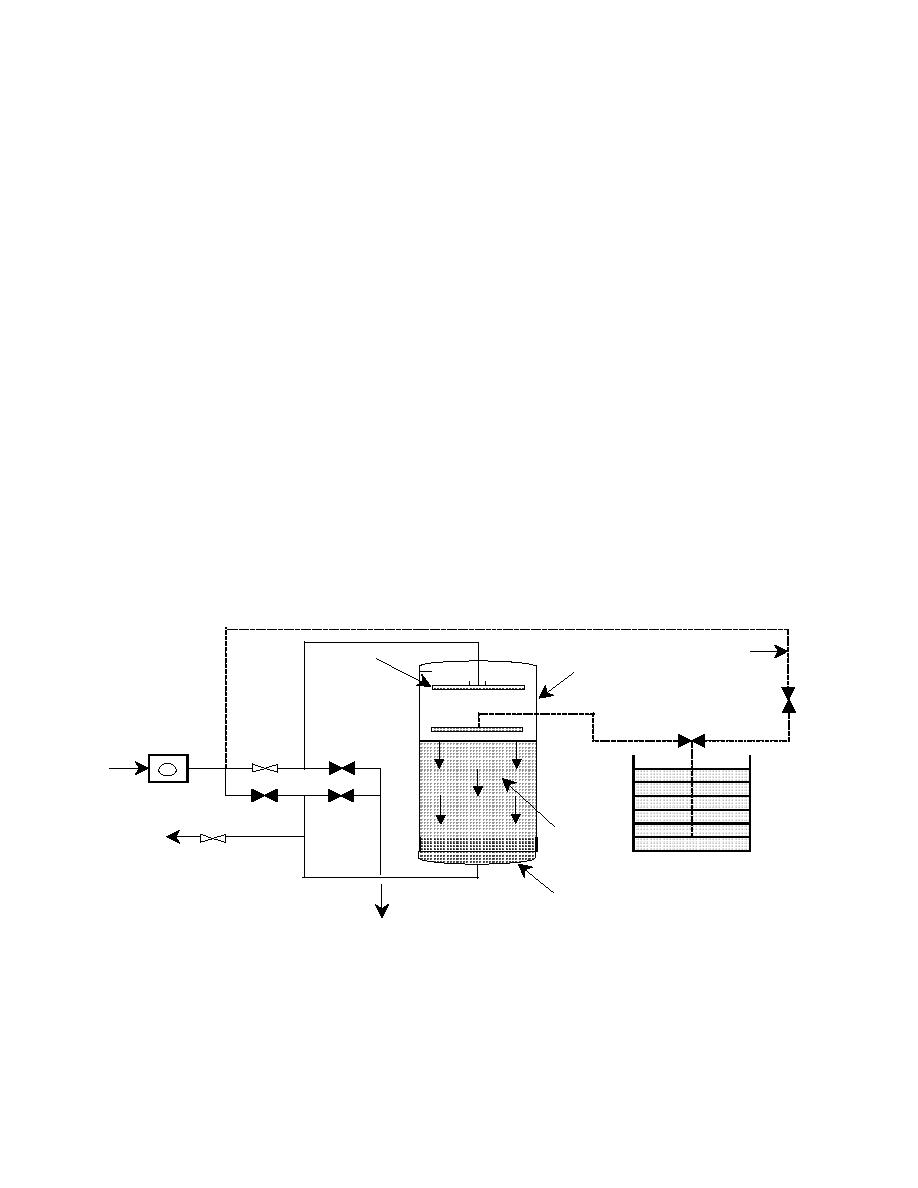

Ion Exchange Process. Several types of ion exchange units are used at

military installations. An ion exchange unit is an open or closed vessel containing an ion

exchange material, also known as resin, which has been deposited on a gravel support

bed. Most ion exchange units operate under pressure, but gravity flow units are also

available. Flow rates vary with the type of equipment but are in the range of 4 to 5.4

liters per second per square meter (6 to 8 gallons per minute per square foot of ion

exchange material surface). A backup ion exchange unit and a storage tank are

typically included to permit an uninterrupted supply of treated water. The manufacturer's

recommendations for proper equipment operation should be posted near the softening

unit. A typical ion exchange hardness softener unit is illustrated in Figure 2-2. Figure 2-3

shows a typical duplex softener.

Figure 2-2. Typical Ion Exchange Unit

Inlet Diffuser/Backwash Collector

Pressure Water

ION EXCHANGE

UNIT

Ejector

Service Inlet

Inlet

Meter

Backwash Inlet Rinse Outlet

Ion

Exchange

Material

Outlet

Regenerant Tank

Supporting

Bed

Waste

17

Previous Page

Previous Page