TM 5-814-3/AFM 88-11, Volume III

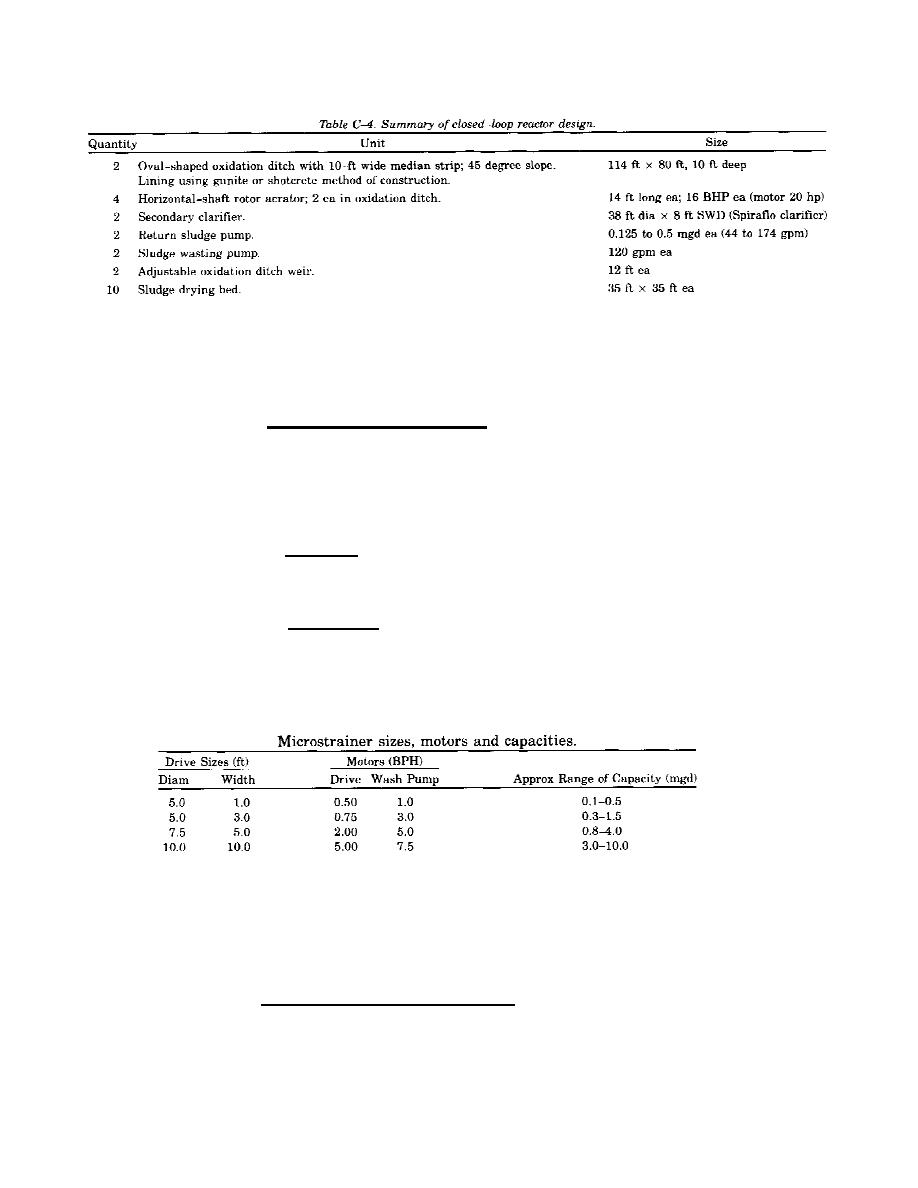

Table C-4 summarizes the design criteria for the horizontal-shaft aerators and multiple-ditch units.

C-9. Microstrainer. (Refer to para 15--4.)

a. Design requirements. Determine the solids loaidng on a microstrainer, treating a secondary effluent

containing 15 mg/L suspended solids, at a flow rate of 0.8 mgd.

b. Calculations and results.

(1) Determine screen surface area, using a hydraulic loading of 600 gal/sq ft/hr.

800,000 gal/day day/24 hr

Surface area '

' 55.6 sq ft, use 60 sq ft;

600 gal/sq ft/hr

Assumingb of the drum surface area is submerged: a drum, 5 ft dia 3 ft wide, would provide 32 sq ft of

submerged screen area.

(2) The solids loading is determined as follows:

Solids loading in lb/mil gal = SS concentration in mg/L8.34;

lb/mil gal

' 125 lb/mil gal;

15 mg/L 8.34

mg/L

125 lb/mil gal 0.8 mgd = 100 lb/day;

c100 lb/day

Solids loading =

' 3.1 lb/sq ft/day.

32.0 sq ft

This loading is high and might require solids removal pretreatment if screen clogging occurs.

The required horsepower is taken from the following tabulation (Source: EPA Design Manual for

Suspended Solids Removal):

C-10. Multi-media filtration. (Refer to para 15--5.)

a. Design requirements. Determine the size of a multi-media gravity filter used in treating a secondary

effluent, assuming a hydraulic loading of 5 gpm/sq ft and a flow rate of 0.7 mgd.

b. Calculations and results.

(1) Surface area:

Surface area = 700,000 gal/day day/1,440 min ' 97.2 sq ft, use 100 sq ft;

5 gal/min/sq ft

Provide two 50 sq ft filter units.

C-32

Previous Page

Previous Page