TM 5-814-3/AFM 88-11, Volume III

b. Anaerobic sludge digestion.

(1) Process description. Anaerobic sludge digestion is the destruction of biological solids using bacteria

which function in the absence of oxygen. This process produces methane gas which can be used as an energy

source and can make anaerobic digestion more economically attractive than aerobic digestion. The larger the

treatment plant, the greater the economic incentive to use anaerobic digestion. However; anaerobic digestion

is considerably more difficult to operate than aerobic digestion. The methane produced could be of great

benefit in cold regions as a supplemental source of heat. Appendix E presents detailed information concerning

insulation of reactors and piping in cold climates. Therefore, the decision to use anaerobic digestion must

carefully evaluate the operational capability of the installation.

(2) Objectives. The objectives of anaerobic digestion are the stabilization of organic solids, sludge

volume reduction, odor reduction, destruction of pathogenic organisms, useful gas production, and the

improvement of sludge dewaterability. Volatile solids typically are reduced by 60 to 75 percent, with final

volatile matter contents of 40 to 50 percent.

(3) Conventional (standard-rate) digestion systems. This type of system will consist of a single or

two-stage process for which tanks will provide for digestion, supernatant separation, and concentration under

the following loadings. Two-stage processes are more applicable for plants having capacities of more than

1 million gallons per day. The retention period in the first stage tank will be 8 days and 22 days in the second

stage tank. The minimum total retention time will be 30 days if the tank is heated to 95 degrees Fahrenheit.

Unit capacities required for separate unheated tanks will be increased in accordance with local climatic condi-

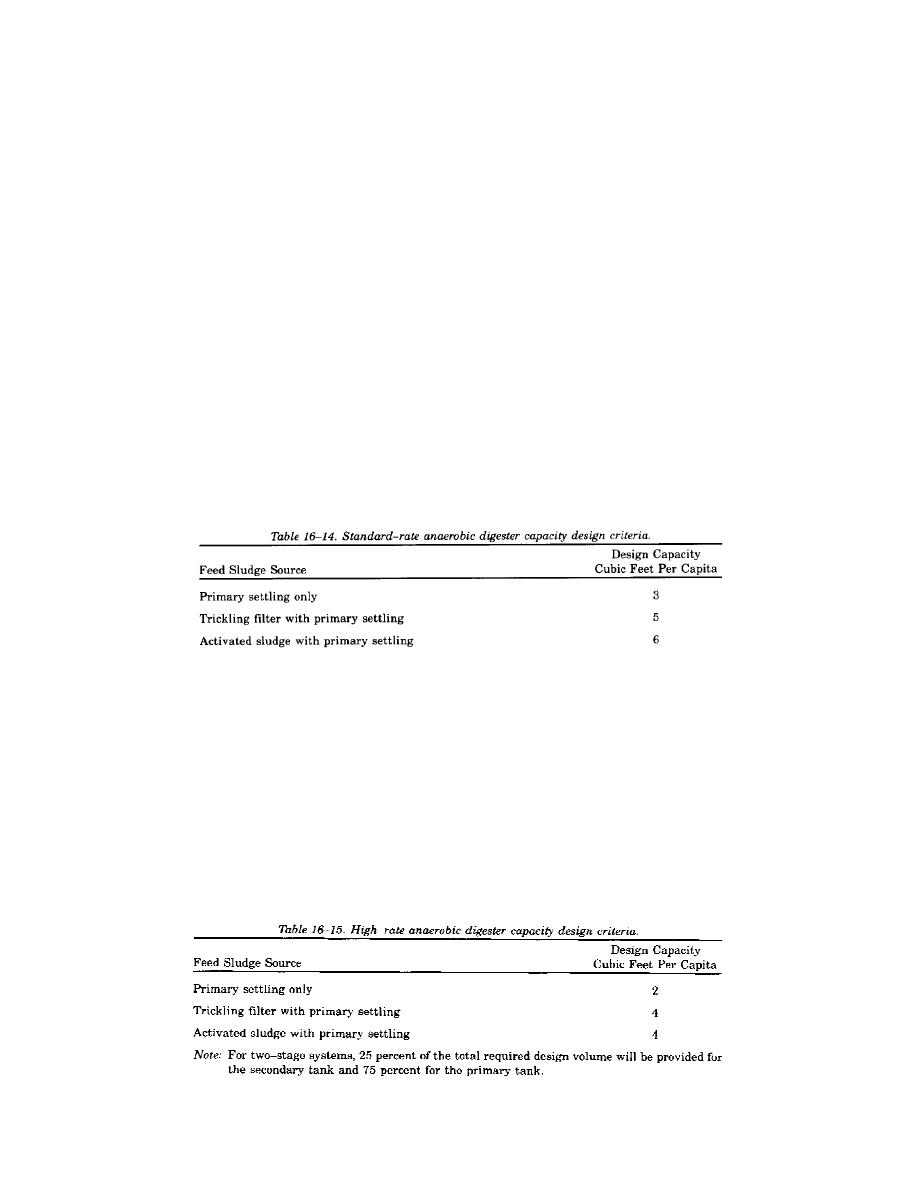

tions but not less than twice the value indicated for each of the three sludge sources in table 16-14.

(4) High-rate digestion. The high-rate digestion process differs from the standard-rate process in that

the solids loading rate is much greater (up to 4 times). The retention period is lower (one-half), mixing

capacity is greater and improved, and the sludge is always heated. High-rate tanks will be those where the

digestion process (accomplished separately from supernatant separation, and sludge concentration and

storage) includes rapid and intimate mixing of raw and digesting sludge in the entire tank contents with an

operating temperature of 95 degress Fahrenheit. The process will be a two-stage system applicable for

treatment plants with capacities greater than 1 million gallons per day and with the primary digestion tank

considered the high-rate tank. If sludge drying beds or ponds are to be used for dewatering of the digested

sludge, the retention time of the solids in the primary digester will be 15 days. If mechanical sludge

dewatering processes are employed, the retention time in the primary digester may be reduced to 10 days.

The secondary digester must be of sufficient capacity to provide for supernatant separation and storage of

digested sludge. The primary digestion tanks will be sized to provide 75 percent of the total design tank

volume (table 16-15).

16-24

Previous Page

Previous Page