TM 5-814-2/AFM 88-11, Vol. 2

t = minimum time in minutes of one pumping

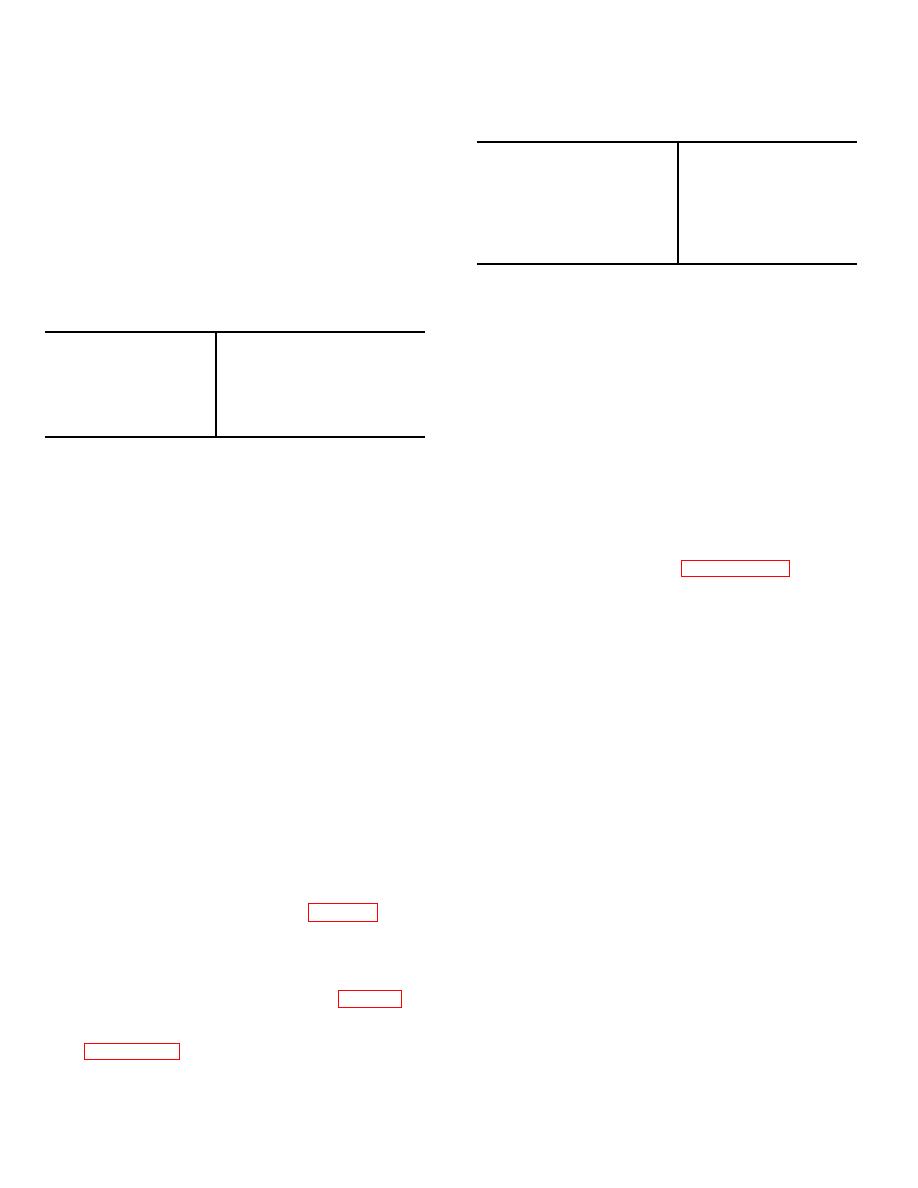

Table 5-2. Required submergence depth to prevent

cycle (time between successive pump

vortexing.

starts), or time required for a speed or

Velocity at diameter D, fps

S, feet

capacity change, and

2

1.0

q = pumping capacity, or increment in capacity

4

2.6

where one or more pumps are operating

5

3.4

and an additional pump is started, or where

6

4.5

pump speed is increased, in gallons per

7

5.7

minute

8

7.1

Constant or adjustable speed pumps driven by squirrel-

Larger, conventional type pump stations will normally be

cage induction motors will be designed for minimum

constructed with wet wells divided into two or more

cycle times as shown in the following table.

sections, or compartments, so that a portion of the

Table 5-1. Minimum pump cycle times.

station can be taken out of service for inspection or

More size, bhp

t, minutes

maintenance. Each compartment will have individual

Less than 20

10 to 15

suction pipes, and will be interconnected with slide or

20 to 100

15 to 20

sluice gates. The floor of the wet well will be level from

100 to 250

20 to 30

the wall to a point 12 to 18 inches beyond the outer

Over 250

as recommended by

edge of the suction bell, and then will be sloped upward

manufacturer

at a minimum 1:1 slope.

The storage volume calculated for small stations

(capacities less than 700 gpm) which utilize two identical

5-4.

Pump controls and instrumentation

constant speed pumps, may be reduced one half by

providing a control circuit to automatically alternate the

includes automatic and manual controls used to

pumps. The storage volume required for variable speed

sequence the operation of pumps, and alarms for

pumps will be based on providing sufficient time for a

indicating malfunctions in the pumping system.

change in capacity when a pump is started or stopped.

Automatic control of pumps will usually be based on the

When a pump is started, the motor must be ramped to

liquid level in the wet well. Paragraph 4-4 contains a

the desired speed, and the pumps already in operation

discussion of the various modes of pump operation,

must be reduced in speed. The time required for this is

pump control systems, and a description of level

usually less than 1 minute. A considerable amount of

detection devices. Manual control of pumps is always

storage is normally available in large sewers which

required in order to operate the pumps during

serve stations utilizing variable speed pumps. This

emergencies, for maintenance purposes, or when

volume may be considered in design by calculating

automatic systems fail. Manual override will be set to

backwater curves for the various operating levels. The

bypass the low level cut-off, but not the low level alarm.

maximum retention time in the wet well will not exceed

b. Selection of control points. A control range of at

30 minutes to prevent septicity.

least 3.0 feet is required between maximum and

c. Suction pipe connections. Pump suction piping

minimum liquid levels in the wet well. A minimum of 6

will be selected to provide a velocity of 4 to 6 feet per

inches will be required between pump control points

second. Pipe should be one or two sizes larger than the

used to start and stop successive pumps, or to change

pump suction nozzle. Vertical pumps installed in a dry

pump speeds. For small stations, the control range may

well which is adjacent to the wet well, will be fitted with a

be less, however control points will not be set closer

90 degree suction elbow, followed by an eccentric

than 3 inches.

reducer and a gate valve. The suction line will be

(1) Constant or adjustable speed pumps

extended through the wall into the wet well, and

require simple on-off switches to start or stop pumps, or

terminated with either a 90 or 45 degree flared elbow, or

to change from one speed step to the next.

an elbow with a flared fitting. The most commonly used

(2) Variable speed pumps require a more

piping arrangements are illustrated in figure 5-3, where D

complex control arrangement. The two basic types of

is the diameter of the flared inlet, and S is the

level control for variable speed operation are (a)

submergence depth.

variable level, and (b) constant level. For variable level

Adequate submergence of the suction inlet is critical to

control, a narrow band of control points is established in

prevent air from being drawn in by vortexing. Minimum

the wet well. Pump speed is then adjusted in steps by

required submergence depths are given in table 5-2 as a

the level detection system (usually a bubbler tube) as

function of velocity. The net positive suction head

the level varies. Pumps operate at maximum

(NPSH) will also be considered when determining S.

See paragraph 5-2c (2).

5-6

Previous Page

Previous Page