*TM 5-813-1/AFM-88-10, Vol. 1

B-2. Site selection

topographic map. Contours, drainage and land use have

been shown but vegetation has been omitted for clarity.

The well must be located within the site boundary for

security and to minimize the length of pipelines. Since

Note that the pumping water level will be above the top

the existing towns use the river plains area as a source

of the screen. Check screen entrance velocity:

of ground water, the flatland in the northeast has been

chosen as a site for test drilling. It has good potential for

recharge from the surface drainage and from the river.

Available records indicate the 100 year flood level to be

approximately at elevation 675 feet; therefore, the site is

not subject to flooding. Three test wells were driven in

B-4. Location

the locations shown on figure B-1 and indicated by PW

The well should be installed near the test pumping well

(pumping well), W1 and W2 (observation wells). A cross

(PW) and observation well (W1) as shown on figure B-1.

section of these three wells is represented by figure 5-3.

The exact location may be influenced by location of

The depth to the bottom of the aquifer is found to be 150

access roads, fences and other details. This leaves

feet. Depth to static water level is 100 ft. A pumping test

room for construction of an additional well for future

gives the following data.

expansion of the facility, north of the observation well

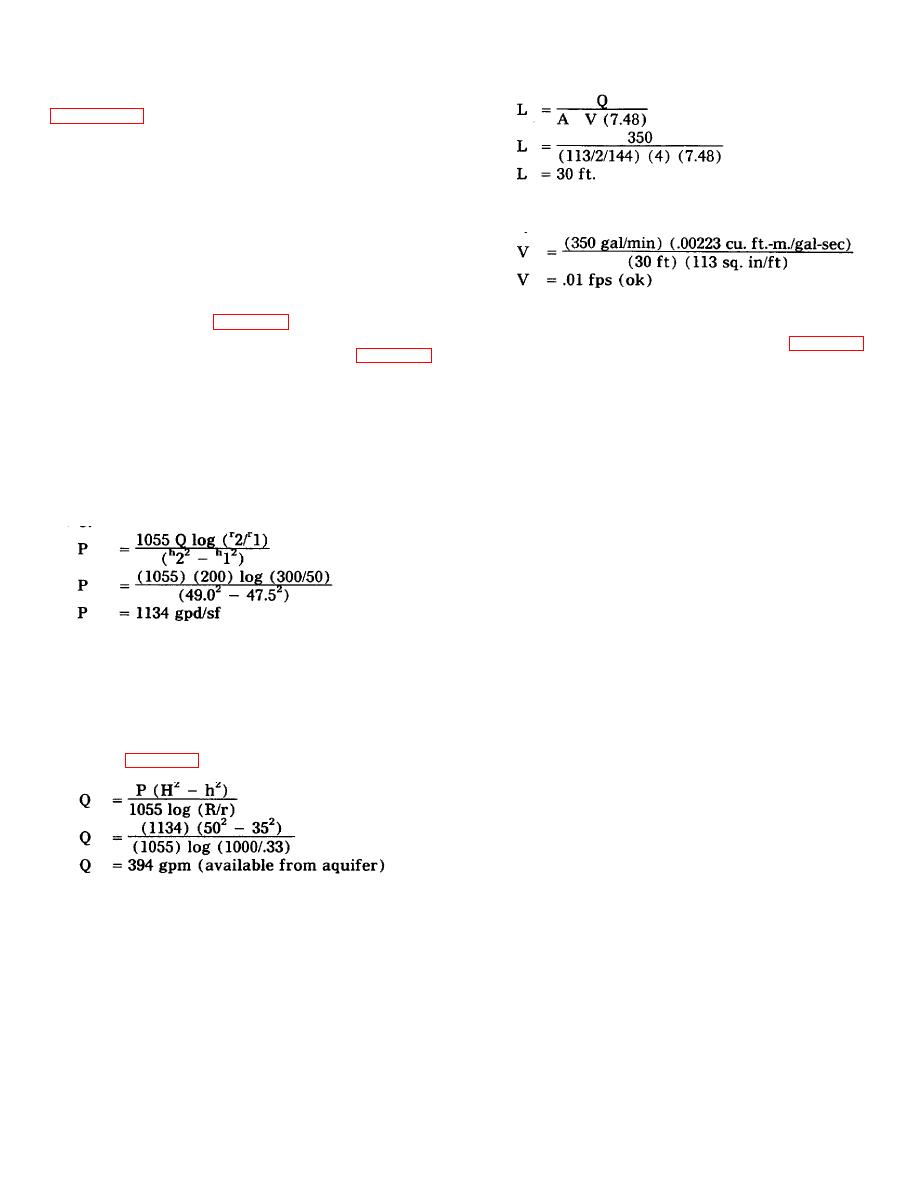

Q = 200 gpm

(W2) which would be beyond the 250 ft. minimum

r

1 = 50.0 ft

spacing required.

h

l = 47.5 ft

r

2 = 300.0 ft

B-5. Water quality

h

2 = 49.0 ft

Samples are taken and analyzed in accordance with

Calculate aquifer permeability using equation 5-3:

Standard Methods. Although the water quality is such

that no treatment is required, chlorine will be added as a

disinfectant in accordance with standard practice.

B-6. Pump selection

An elevated storage tank will be installed in the area of

the facility to maintain a 40 psi minimum distribution

system pressure at the maximum ground elevation of

B-3. Size the well

820 ft. Approximately 1500 lin. ft. of 6" pipe will be

A yield of 350 gpm is required. Table 53 indicates that a

required from the well to the tank. Calculate the TDH

pump of 6" diameter will be required and the smallest

using equation 5-6.

well casing (and screen size) should be 8". (Current

a.

Suction head is the distance from the ground

pump manufacturers and screen manufacturers

(pump level) to the lowest elevation of water in the well.

literature should be reviewed to confirm this.) Assuming

Assume this would be at the top of the screen. Add the

R = 1000 ft. and a maximum drawdown of 15 ft. as

distance to the water table plus depth of top of screen.

depicted in figure 5-4, calculate the available yield:

HS = 100 + 20 = 120 ft.

b.

Discharge head is the difference in elevation

from the pump to the water level in the storage tank.

Calculate the difference in ground elevation and add the

required pressure. Assume the well is at El. 695.

HD = (820 - 695) + (40) (2.31) = 217 ft.

c.

Friction head is calculated by methods

The well should be designed to be drilled to the bottom of

presented in TM 5-813-5. Add head loss in pipe plus

the aquifer. Screen manufacturer's literature shows that

loss in fittings.

an 8" diameter telescoping screen has an intake area of

HF = (18 ft/1000) (1.5) + 10 = 37 ft.

113 sq. in. per ft. of length; calculate length of screen

d.

Velocity loss is calculated from the equation.

required using equation 5-5:

B-2

Previous Page

Previous Page