TM 5-818-8/AFJMAN 32-1030

Table 6-1. Recommended Geotextile Mininmum Strength Re-

in case of UV protected and low UV susceptible

quirements.

polymer geotextiles. The geotextile should be

loosely laid, free of tension, folds, and wrinkles.

1

2

Type Strength Test Method

Class A

Class B

When used for streambank protection, where cur-

Grab Tensile

ASTM D

4632

90

200

rents acting parallel to the bank are the principal

Elongation (%)

ASTM D

4632

15

15

erosion forces, the geotextile should be placed with

Puncture

ASTM D

4833

80

40

the longer dimension (machine direction) in the

ASTM D

4533

Tear

50

30

ASTM D

3884

Abrasion

55

25

direction of anticipated water flow. The upper

ASTM D

4632

Seam

80

180

strips of the geotextile should overlap the lower

Burst

ASTM D

3786

320

140

strips (fig 6-3). When used for wave attack or cut

1

Fabrics are used under conditions more severe than Class B

and fill slope protection, the geotextile should be

such as drop height less than 3 feet and stone weights should

placed vertically down the slope (fig 6-3), and the

not exceed 250 pounds.

upslope strips should cover the downslope strips.

`

Fabric is protected by a sand cushion or by zero drop height.

Stagger the overlaps at the ends of the strips at

b. Construction Considerations.

least 5 feet. The geotextile should be anchored at

(1) Site preparation. The surface should be

its terminal ends to prevent uplift or undermining.

cleared of vegetation, large stones, limbs, stumps,

For this purpose, key trenches and aprons are used

trees, brush, roots, and other debris and then

at the crest and toe of the slope.

graded to a relatively smooth plane free of obstruc-

tions, depressions, and soft pockets of materials.

(3) Overlaps, seams, securing pins. Adjacent

(2) Placement of geotextiles. The geotextile is

geotextile strips should have a minimum overlap

unrolled directly on the smoothly graded soil

of 12 inches along the edges and at the end of

surface. It should not be left exposed to UV

rolls. For underwater placement, minimum over-

deterioration for more than 1 week in case of

lap should be 3 feet. Specific applications may

untreated geotextiles, and for more than 30 days

require additional overlaps. Sewing, stapling, heat

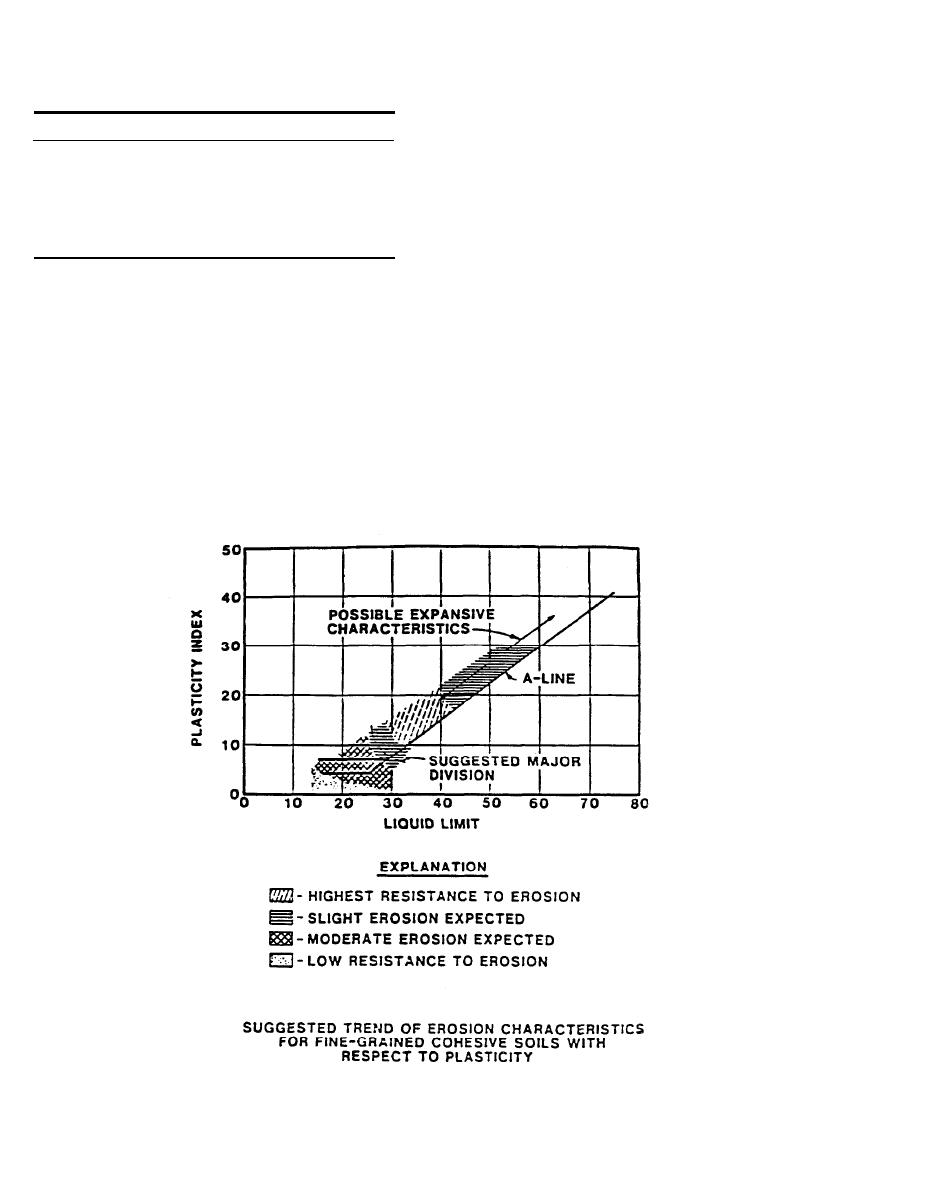

Figure 6-1. Relationship between Atterberg Limits and Expected Erosion Potential.

6-2

Previous Page

Previous Page