TM 5-818-4/AFM 88-5, Chap. 5

(2) Hand cone penetrometer. The hand cone pene-

to suspect adequate compaction has or has not been

trometer offers a rapid means of checking density re-

achieved.

quirement of some compacted backfills. The process

involves the correlation of penetration resistance with

known in-place densities as determined by either the

sand-cone or the rubber-balloon method.

(a) Cone penetration resistance is a measure-

ment of soil bearing capacity. Since bearing capacity is

dependent on shear strength and thus density, the

hand cone penetrometer is an indirect measurement of

density. Because shear strength is a function of any

pore air and pore water pressures that may be gener-

ated by a shearing action of soils containing pore wa-

ter, the method is applicable only to free-draining

materials where pore pressures are dissipated as fast

as they are generated. Penetration resistance can also

be drastically influenced by the obstruction of gravel-

size particles. Therefore, the method is applicable only

to sands with 100 percent passing the U.S. Standard

No. 4 sieve (4.76 mm) and no more than 15 percent

passing the U.S. Standard No. 200 sieve (0.074 mm).

(b) A plot of hand-cone sounding resistance ver-

sus depth of sounding will result in an approximate

linear relationship for homogenous materials of rela-

tively constant density for depths of sounding ranging

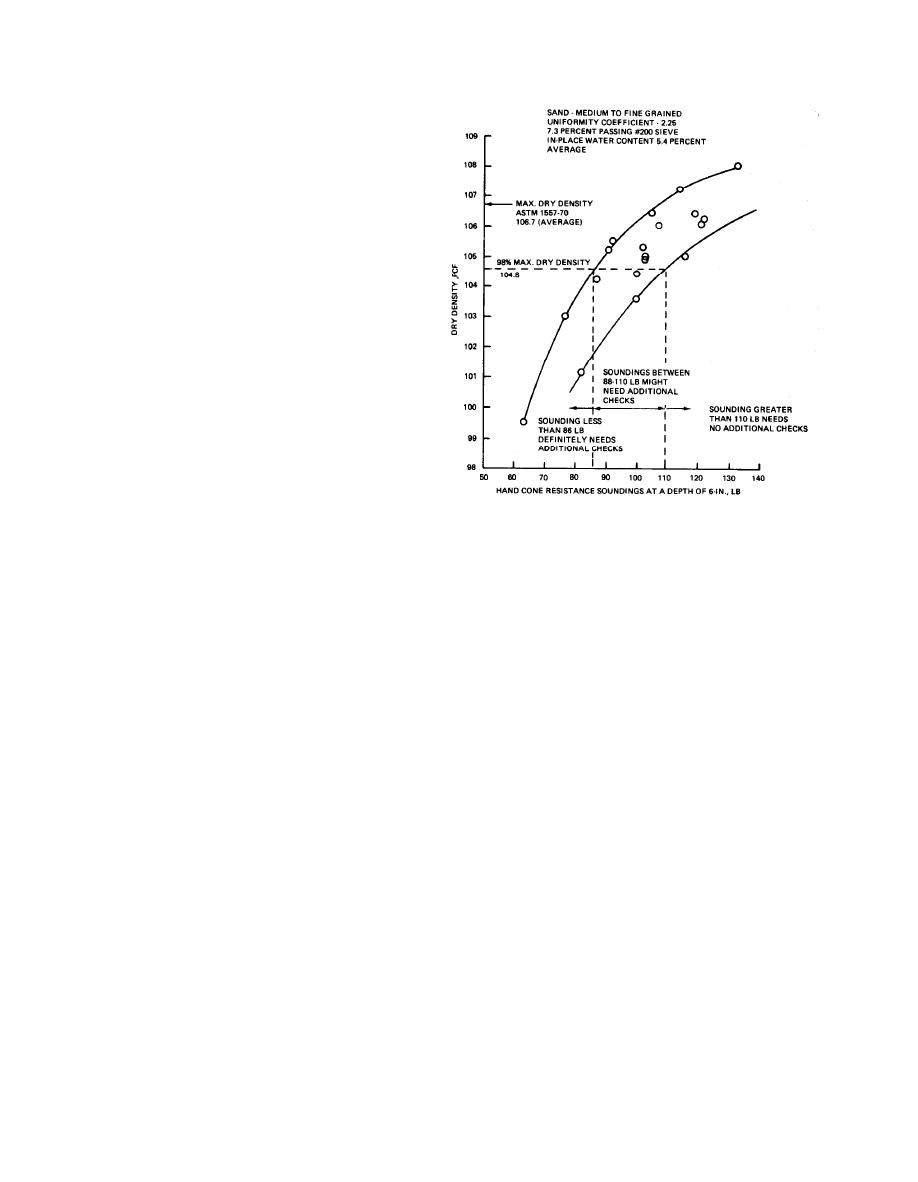

Figure B-7. Correlation between dry density and hand cone resist-

from approximately 2 inches to 20 inches depending

ance at a depth of 6 inches below the surface.

on the geometry and size of the cone point and mate-

(c) The correlation between sounding resistance

rial type. Correlations may be made between known

and known in-place dry densities (fig. B-7) is made di-

in-place densities and either the angle of inclination

rectly without knowing water content at each sound-

between sounding resistance and depth of penetration

ing location. Although sounding resistances are af-

or the sounding resistance at a given depth. The range

fected by water content for the dry, moist, and 1 to 2

of known in-place density must be sufficient to estab-

percentage points above optimum state, the range of

lish a trend between sounding resistance and density.

possible water content in the moist state does not sig-

Correlations between density and sounding resistance

nificantly affect sounding resistance.

at a given depth is the simplest correlation since the

(d) The hand cone penetrometer is ideally suited

angle of inclination does not have to be computed.

for use in confined zones where sand is used as backfill

Figure B-7 shows a case example of a correlation be-

and where rapid control aids are needed to determine

tween dry density and sounding resistance measured

if adequate compaction has been achieved. With a lit-

at 6 inches below the surface. Contract specification

tle practice, a hand-cone sounding can be -made in less

required a minimum acceptable dry density of 104.7

than 1 minute.

pounds per cubic foot (98 percent of the maximum dry

density according to the compaction method described

d. Possible sources of errors. Since the decision to

in ASTM D 1557). Figure B-7 also indicates that all

accept or reject a particular part of a backfill is primar-

soundings with resistances of 110 pounds or more cor-

ily dependent upon the results of in-place density con-

responded to densities greater than 104.6 pounds per

trol tests, it is important for the inspector to be famil-

cubic foot. Therefore, no additional standard density

iar with the possible sources of errors that might cause

checks are needed beyond the routine tests. When all

an inaccurate test result. Some of the more likely

soundings with resistance of 86 pounds and below cor-

sources of errors for the sand-cone, rubber-balloon,

respond to densities below 104.6 pounds per cubic

and nuclear moisture-density methods are discussed

foot, it is evident that sufficient compaction has not

below. All tests that are suspected to be in error must

been achieved and additional standard density checks

be repeated.

are definitely needed for an acceptance or rejection

(1) Sand-cone method. The major sources of possi-

decision. Sounding with resistances between 86 and

ble error are as follows:

110 pounds may or may not need additional density

(a) The sand-cone method relates the bulk den-

checks depending on whether the inspector has reason

sity of a standard sand to the known weight of the

B- 10

Previous Page

Previous Page