TM 5-818-4/AFM 88-5, Chap. 5

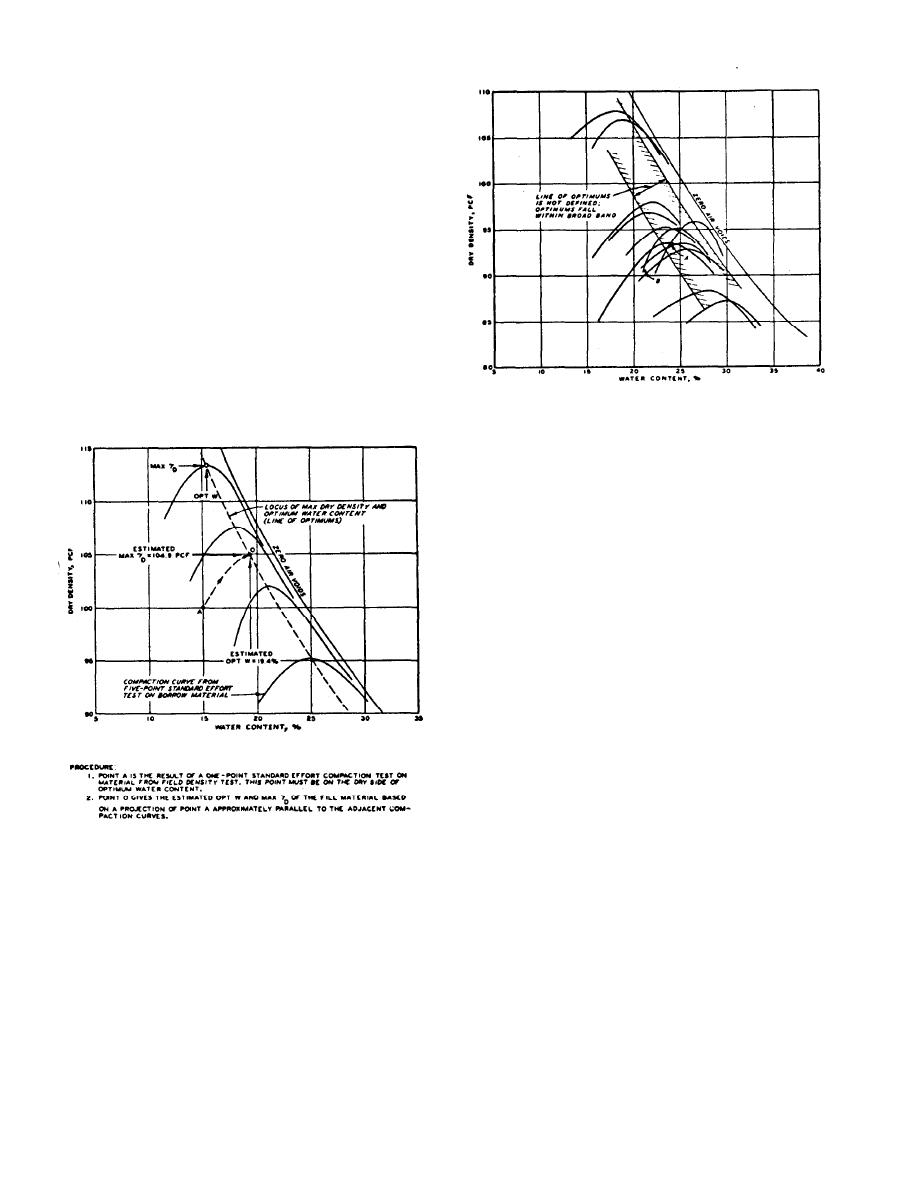

well defined in the figure, and the compaction curves

are approximately parallel to each other; consequent-

ly, the one-point compaction method could be used

with a relatively high degree of confidence. In figure

B-5, however, the optimums do not define a line, but a

broad band. Also, the compaction curves are not paral-

lel to each other and in several instances cross on the

dry side. To illustrate the error that could result from

using the one-point method, consider the field density

and water content shown by point B in figure B-5.

Point B is close to three compaction curves. Conse-

quently, the correct curve cannot be determined from

the one point. The estimated maximum dry density

and optimum water content could vary from about

92.8 pounds per cubic foot and 26 percent, respective-

ly, to 95.0 pounds per cubic foot and 24 percent, re-

spectively, depending on which curve was used. There-

fore, the one-point method should be used only when

the basic compaction curves define a relatively good

Figure B-5. Illustration of possible error using one- and two-point

line of optimums.

compaction methods.

(para B-8a), and dry densities are computed. The re-

sults are used to identify the appropriate compaction

curve for the material test (fig. B-6). The data shown

in figure B-6 warrant the use of the two-point compac-

tion test since the five-point compaction curves are not

parallel. Using point A only as in the one-point test

method would result in appreciable error as the shape

of the curve would not be defined. The estimated com-

paction curve can be more accurately defined by two

compaction points as shown. Although the two-point

method is more accurate than the one-point method,

neither method would have acceptable accuracy when

applied to the set of compaction curves shown in

figure B-5.

(3) Rapid one-point test for sands. A rapid check

test for compaction of uniform sands (SP to SM) with

less than 10 percent fines (minus No. 200 sieve) is a

modified one-point test. The ovendry sand is com-

pacted in a 4-inch-diameter mold using CE 55 (modi-

fied) effort. Correlation with standard compaction

tests is required to confirm the validity of test results

Figure B-4. Illustration of one-point compaction method.

for different sands used on each project.

(2) Two-point compaction test results. In the two-

(4) USBR rapid compaction control method. De-

point test, one sample of material from the location of

tails of this method are described in the USBR Earth

the field density test is compacted at the fill water con-

Manual (app A), The test is applicable to fine-grained

tent if thought to be at or on the dry side of optimum

(100 percent minus No. 4 sieve) cohesive soils with li-

water content (otherwise, reduced by drying to this

quid limits less than 50. The method, however, is ap-

condition) using the same equipment and procedures

plicable to soils containing oversize particles providing

used in the five-point compaction test. A second sam-

the proper corrections, as stated in EM 1110-2-1911,

ple of material is allowed to dry back about 2 to 3 per-

Appendix B, are applied. It is a faster method than the

centage points dry of the water content of the first

standard compaction test and is often more accurate

sample, and then compacted in the same manner. Af-

than other methods. The method usually requires add-

ter compaction, water contents of the two samples are

ing water to or drying back sampled fill material, and

determined by ovendrying or other more rapid means

thorough mixing is needed to obtain uniform drying or

B-6

Previous Page

Previous Page