CEMP-E

EI 02G001

01 July 1997

To use a vibratory hammer underwater or, for that matter, under the power pack, it is important to both

ensure that water does not seep into the case and to limit the motor case drain pressure relative to the

main vibratory case. The pressure of the motor case must be no higher than 2.75 bar (40 psi) above the

vibratory case, lest the motor shaft seal blow oil into the vibratory case.

To determine the effective driving depth of the hammer, measure the vertical distance from the motor

case drain outlet up to the power pack reservoir. If this distance is less than 9-12m (30' - 40'') and the

hammer is not submerged underwater, the hammer should operate satisfactorily as it is. Should the

depth be in this range and the hammer be submerged, the case vent should be removed and a hose be

attached that runs to the surface, and all leaks of the vibratory hammer must be completely stopped

and sealed.

For depths greater than 12m (40'), the motor shaft seals must be protected. To do this, remove the

case vent and attach an air hose to the exciter case. This hose must be pressurized by an air

compressor on the surface, and the case must be pressurized to the pressure of the water surrounding

the vibrator at the depth the vibrator is used; however, the vibratory case pressure in any case must not

exceed the motor case pressure by more than 1.4-2 bar (20 - 30 psi) or the shaft seal(s) will rupture.

Figure 3-36. Techniques for using hydraulic vibratory hammer underwater.

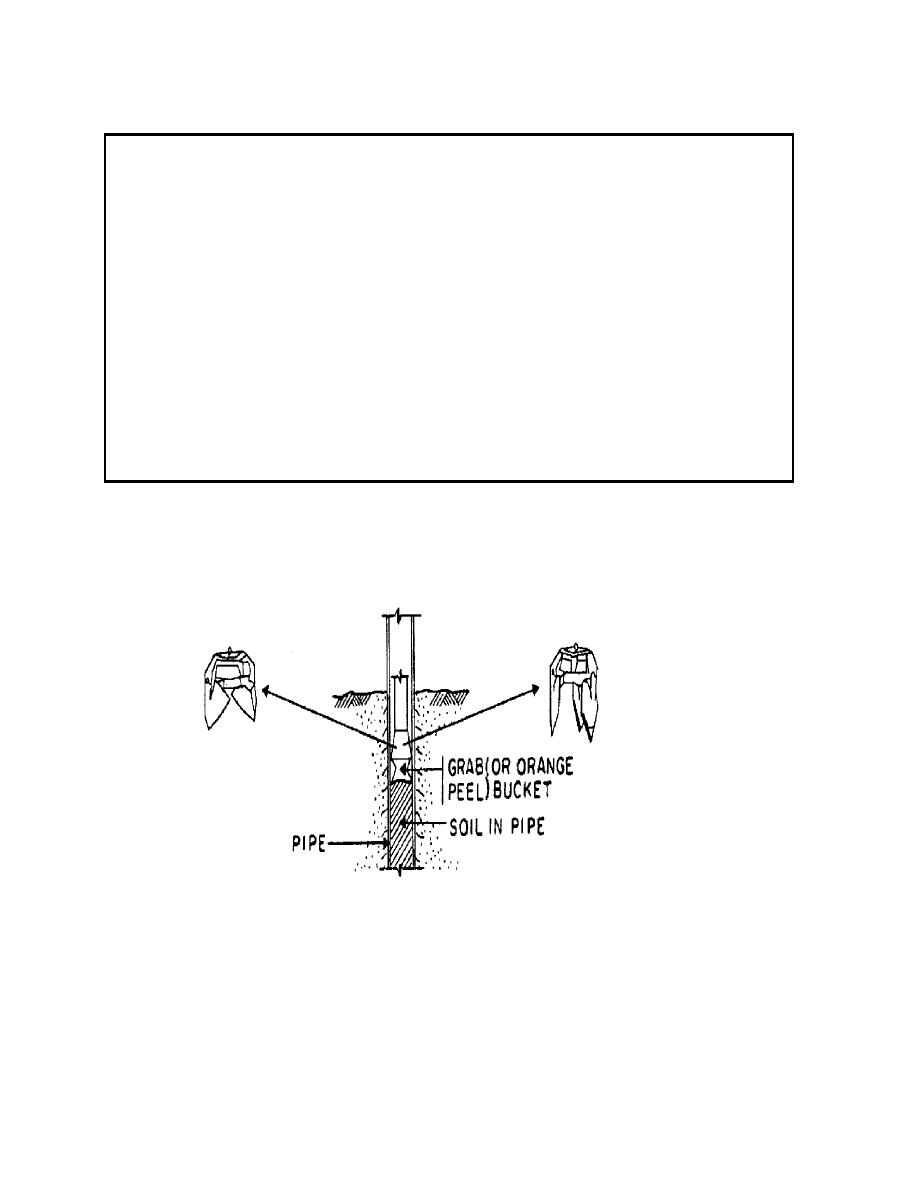

Figure 3-37. Bucket for plug removal.

3-57

Previous Page

Previous Page