EI 02G001

CEMP-E

01 July 1997

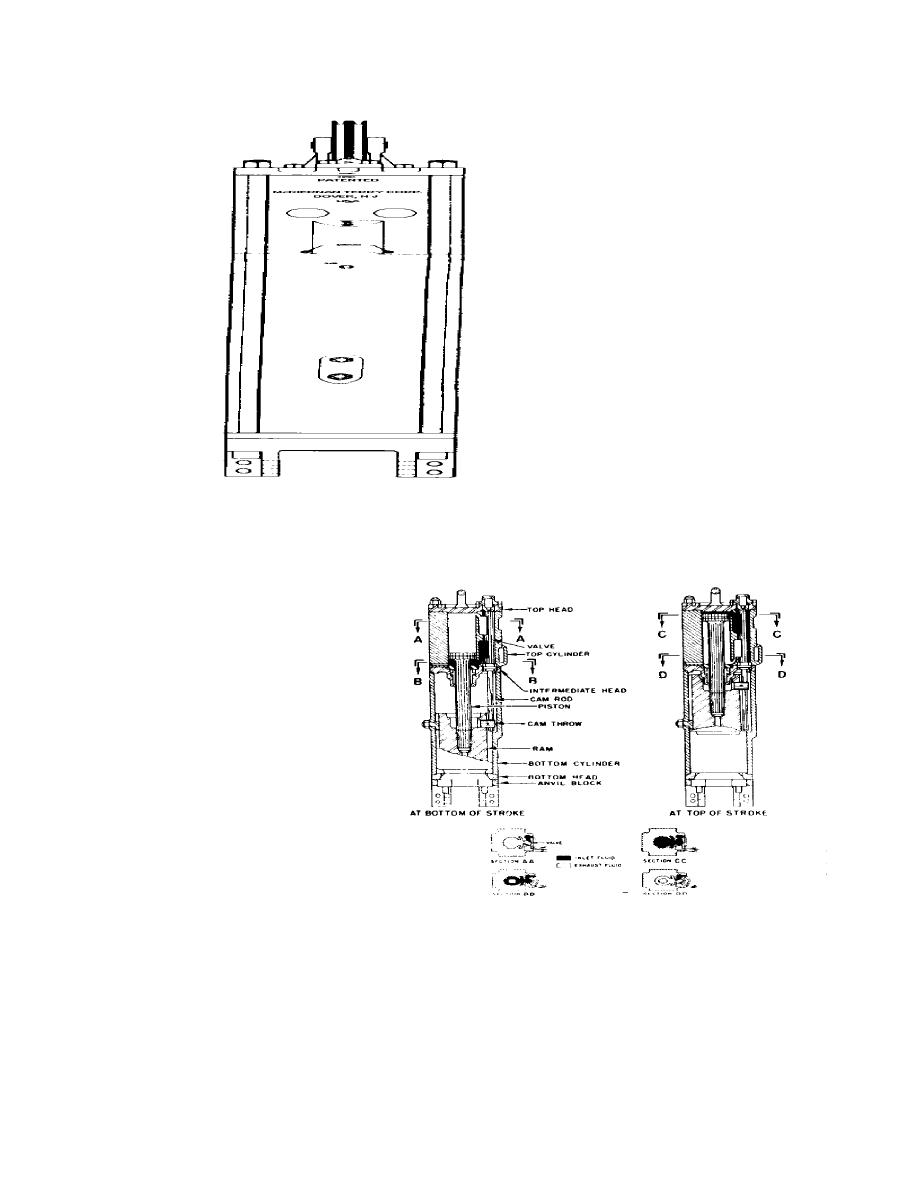

Figure 3-7a. Typical double-acting air/stream hammer.

The ram carries a rigidly connected cam throw (some

double acting hammers use a fluid valve) which

engages a camrod suspended in the intermediate

head of the hammer. In operation, the motive fluid

first enters the inlet port and flows through the lower

opening of the valve to the underside of the piston.

The top opening of the valve completes a path from

the topside of the piston to the exhaust port. As the

fluid lifts the piston, thus lifting the ram, the lugs of the

cam throw slide past the edges of the cam rod until, at

the top of the stroke, they engage a spiral portion of

the cam rod, causing it to rotate. The valve connected

to the top of the cam rod also rotates, allowing the inlet

motive fluid on the underside of the piston to escape

through the exhaust port. The ram then falls, its

velocity increased by the fluid pressure on the top of

the piston. The cam throw lugs slide down where

another spiral portion of the cam rode is engaged. The

cam rod rotates; rotating the valve to the original

position, and the motive fluid path reverses.

Figure 3-7b. Interior view of air/ateam hammer.

3-32

Previous Page

Previous Page