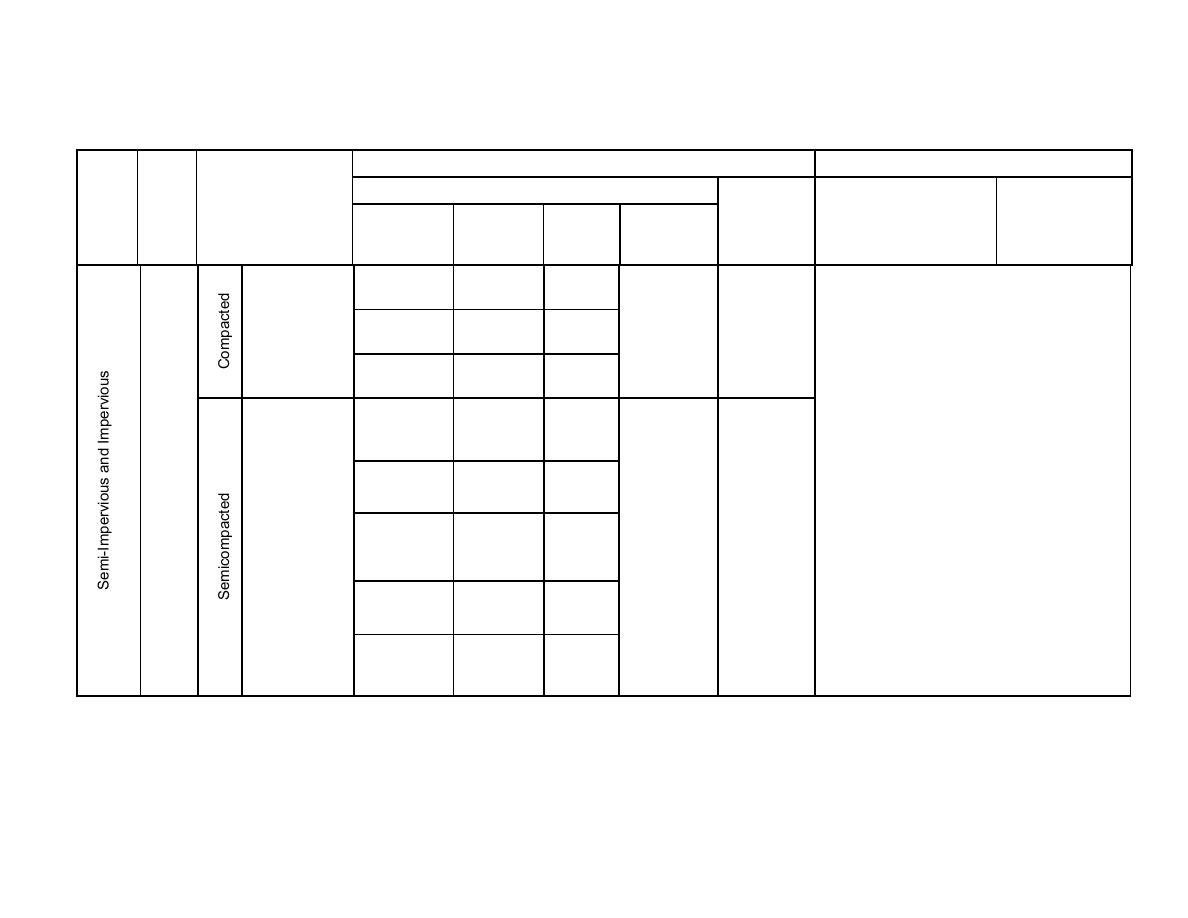

Table 8-2.1

A Summary of Densification Methods for Building Foundations

Soil

Soil

Degree of

Fill and Backfill

Deep Foundation Deposits

Group

Types

Compaction

Typical Equipment and Procedures for Compaction

Field

Compaction Methods

Field Control

Control

Equipment

No. of

Lift

Placement

Phases or

Thick.,

Water

Coverages

mm (in)

Content

(A) Surface compaction by equipment

GM

90 95%

Rubber tired

2-5

200 (8)

Optimum

Control

and procedures shown @ left is feasible

ASTM D 1557

roller (a)

coverages

water

samples at

GC

only if material is at proper water

maximum

content

intervals to

Sharpefoot

4-8 passes

150 (6)

content.

density

based on

determine

SM

roller (d)

ASTM D

degree of

(B) Densification of soils is controlled by

SC

1557

compaction

Power hand

Indefinite

100 (4)

consolidation process:

ML

tamper ( c )

Preload fills*

(A) Optimum

CL

(A) Control

85-90%

Rubber tired

2-4

250 (10)

water content

Lowering of groundwater table

samples as

ASTM D 1557

roller (a)

coverages

based on

OL

ASTM D 1557.

noted

maximum

Drying

OH

above, if

density

___________________________

(B) Wet side

Sharpefoot

4-8 passes

200 (8)

needed.

maximum

MH

* Consolidation may be accelerated by

roller (d)

water content

(B) Field

means of vertical drains.

at which one

CH

control

Crawler

3

150 (6)

material can

Field control exercised by observation of

satisfactorily

exercised

type tractor

coverages

pore pressures and surface settlements.

operate,

by visual

(b)

minimum water

inspection

content

of action of

Power hand

Indefinite

150 (6)

required to

bond particles

compaction

tamper (d)

(and not result

equipment.

in voids or

Control of

Indefinite

150

honey-combed

materials.)

construction

200 (6-

equipment

8)

Note: The above requirements will be adequate in relation to most construction. In special cases where tolerable settlements are unusually small, it may be necessary to employ additional

compaction equivalent to 95-100% of CE55 compaction effort. A coverage consists of one application of the wheel of a rubber tired roller of the treads of a crawler type tractor over each

point in the area being compacted. For a sharpefoot roller drum over the area being compacted.

a. Rubber tired rollers having a wheel load between 18,000 and 25,000 lbs. and a tire pressure between 80 and 100 psi.

b. Crawler type tractors weighing not less than 20,000 lbs and exerting a foot pressure not less than 6 psi.

c. Power hand tamper weighing more than 100 lbs: pneumatic or operated by gasoline engine.

d. Sharpfoot rollers having a foot pressure between 250 and 500 psi and tamping 7-10 tamp lengths with a face area between 7 and 16 sq. inches.

Previous Page

Previous Page