MIL-HDBK-1110

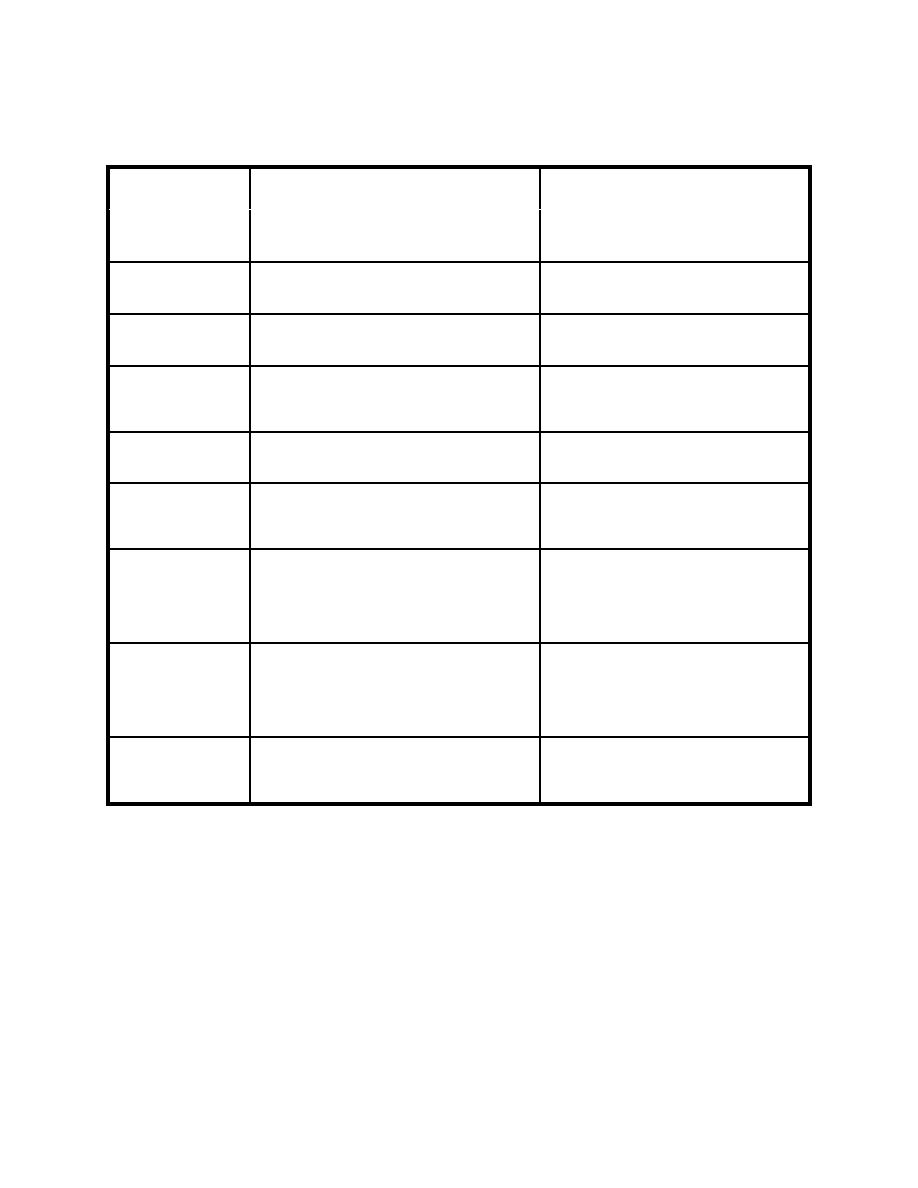

Table 16

Inspection Steps

Action

Brief Description

Tools (Not all may be needed for

any particular job)

Contract specification, material

Determine specified coating,

Review contract

technical data sheets, Figure 21

surface preparation, application

specification

procedure and final appearance

and submittals

Visit job site

Ensure that the contractor

understands the scope and

difficulties of the job

Discuss painting job with

Contract specification, visual

Conduct

contractor

standards, material technical

preconstruction

data sheets

conference

Ensure that repairs are complete,

Carry out

oil, grease, weld splatter are

presurface

removed, surrounding area is

preparation

protected from potential damage

inspection

Ensure adequate material is on the Paddle for stirring

Inspect coating

material

job site; examine age and condition

of coatings and storage facilities

Psychrometer and chart, surface

Assess ambient

Throughout the painting job,

thermometer, and weather data

conditions

measure air and surface

temperature, relative humidity and

dew point, and wind velocity

Comparator, surface preparation

Inspect surface

As required, inspect surfaces for

standards (SSPC VIS 1 and VIS 3,

preparation

cleanliness, profile, removal of

NACE TM-01), felt for chalk

loose paint, chalk, mildew, soil

measurement, visual standards

and grease

for chalk and mildew assessment,

instrument for measuring profile

Material technical data sheets,

Inspect coating

Ensure specified materials are

wet and dry film thickness gages

application

used; check thinner and amount of

thinning; measure dry film

thickness and determine that one

layer has dried/cured properly

before another is applied

Examine film for thickness,

Camera, dry film thickness gage,

Final approval

appearance, uniformity, and defectsholiday detector (if needed),

of complete

magnifying glass, adhesion

system

tester

143

Previous Page

Previous Page