MIL-HDBK-1110

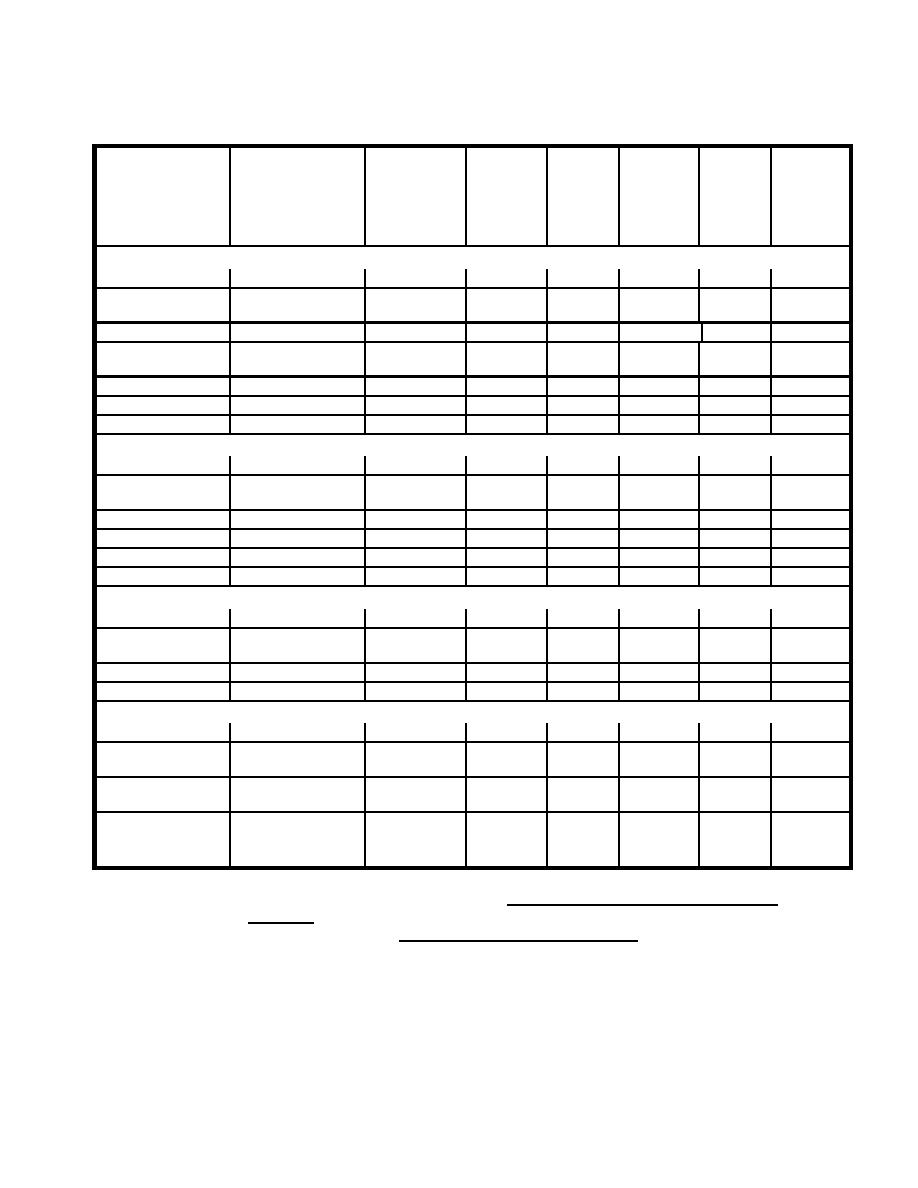

Table 9

Typical Physical Characteristics of Abrasives (1)

Shape

Specific

Bulk

Color

Free

Degree

Gravity Density

Silica

of

(pounds

Wt

Dusting

per

Percent

cubic

foot)

Naturally Occurring Abrasives

(Mohs Scale)

Sands:

Silica

5

Rounded

2 to 3

100 White

90 +

High

Mineral

5 to 7

Rounded

3 to 4

123 Variable

<5

Medium

Flint

6.7 to 7

Angular

2 to 3

80 Lt.

90 +

Medium

Grey

Garnet

7 to 8

Angular

4

145 Pink

Nil

Medium

Zircon

7.5

Cubic

4.5

185 White

Nil

Low

Novaculite

4

Angular

2.5

100 White

90 +

Low

By-Product Abrasives

(Mohs Scale)

Slags:

Boiler

7

Angular

2.8

85

Black

Nil

High

Copper

8

Angular

3.3

110

Black

Nil

Low

Nickel

8

Angular

2.7

85

Green

Nil

High

Walnut Shells

3

Cubic

1.3

45

Brown

Nil

Low

Corn Cobs

4.5

Angular

1.3

30

Tan

Nil

Low

Manufactured Abrasives

(Mohs Scale)

Silicon

9

Angular

3.2

105 Black

Nil

Low

Carbide

Aluminum Oxide 8

Blocky

4.0

120 Brown

Nil

Low

Glass Beads

5.5

Spherical 2.5

100 Clear

67

Low

Metallic Abrasives

(Rockwell C)

Cast Steel (2) as spec. or

Spherical 3 to 10

Grey

Nil

Shot & Grit

range 35-65 RC

or Angular

Malleable Iron range:

Spherical 3 to 10

Grey

Nil

Shot or Grit 28-40 RC

or Angular

Chilled

Cast Iron

range:

Spherical 3 to 10

Grey

Nil

Shot or Grit 57-65 RC

or Angular

NOTES:

(1)

Taken from SSPC SP COM, Steel Structures Painting

Manual, Systems and Specifications, Vol. 2, p. 17,

and Vol. 1 of Good Painting Practice, p. 34.

(2)

Represents 85 percent of the metallic abrasives

used.

89

Previous Page

Previous Page