MIL-HDBK-1110

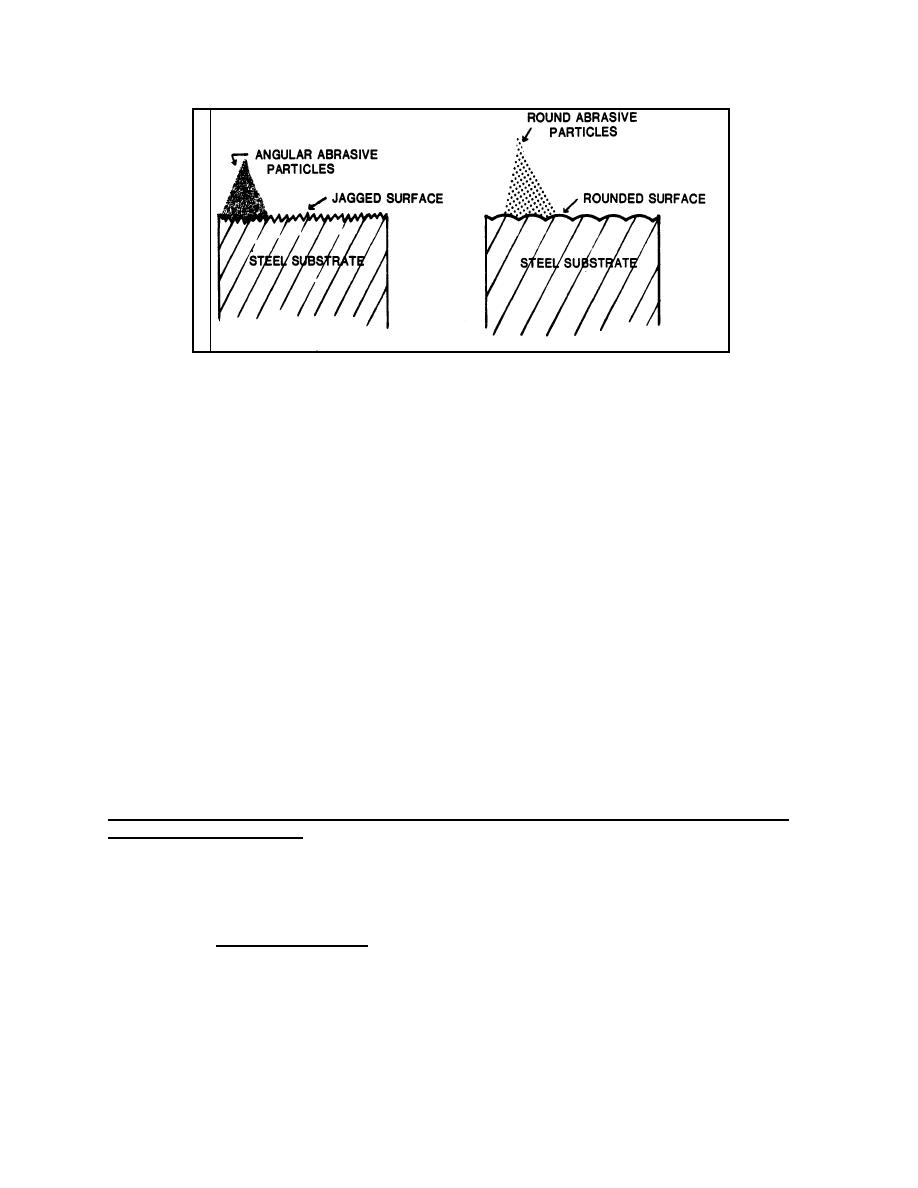

Figure 4

Drawing Illustrating Effect of Shape of Abrasive Particle on

Contour of Blast-Cleaned Metallic Substrate

d) Specific Gravity. Generally the more dense a

particle, the more effective it is as an abrasive. This is

because it takes a certain amount of kinetic energy to remove

contaminants from the surface and the kinetic energy of an

abrasive particle is directly related to its density (specific

gravity).

e) Breakdown Characteristics. Abrasive particles

striking the surface at high speeds are themselves damaged. The

way in which they fracture (breakdown) and/or in which they

change their shape and size is called their breakdown

characteristic. An excessive breakdown rate results in a

significant increase in dusting, requires extra surface cleaning

for removal of breakdown deposits, and limits the number of times

the abrasive can be reused.

f) Water-Soluble Contaminants. ASTM D 4940,

Conductimetric Analysis of Water Soluble Ionic Contamination of

Blasting Abrasives describes a conductivity test for determining

the level of contamination of metallic, oxide, slags, and

synthetic abrasives by water-soluble salts. SSPC AB 1 requires

that the conductivity of the test solution be below 100

microsiemens.

6.7.1.4

Abrasive Types. Abrasives fall into seven general

categories: metallic, natural oxides, synthetic, slags,

cellulose (such as walnut hulls), dry ice pellets (carbon

dioxide), sodium bicarbonate, and sponge. A summary of typical

properties of some of these abrasives is found in Table 9.

88

Previous Page

Previous Page