TM 5-852-5/AFR 88-19, Volume 5

where aggregate is available and the foundation

replacement is very high in remote locations so that

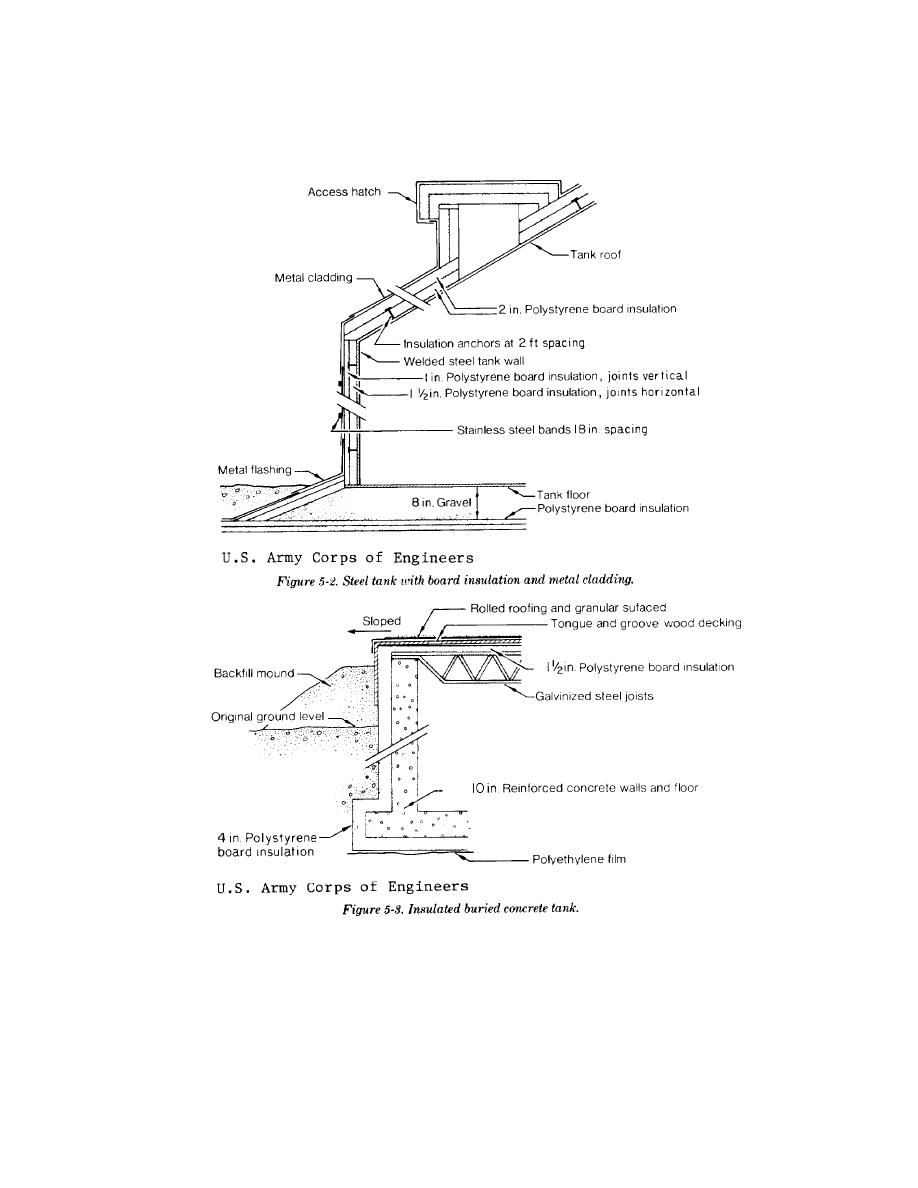

conditions permit slab construction. Concrete tanks

the type of coating initially selected should be of

will be covered with earth and insulated if necessary

high quality and properly applied. Cathodic protec-

to reduce heat losses as shown in figure 5-3.

tion is also required.

b. Insulation. Successful tank insulation has been

Seismic conditions must be evaluated prior to selec-

tion of a rigid concrete tank. Welded steel tanks are

provided by earth cover, wood, glass fiber, cellular

more cost effective for high-risk seismic areas.

glass, polyurethane and polystyrene block materials.

a. Corrosion protection. Steel water tanks must

Tanks can also be enclosed with a protective shell.

be painted in accordance with applicable standards.

Such an exterior shell is either constructed against

Manufacturers'

recommendations

regarding

the tank or a walkway provided between the tank

acceptable temperature limits for the application of

and the exterior wall as shown in figure 5-4. The air

these paints must be strictly followed to avoid pre-

gap and the wind protection will reduce heat losses,

mature failure. The cost of sandblasting and liner

5-2

Previous Page

Previous Page