TM 5-852-5/AFR 88-19, Volume 5

Upflow and sludge blanket clarifiers are not as

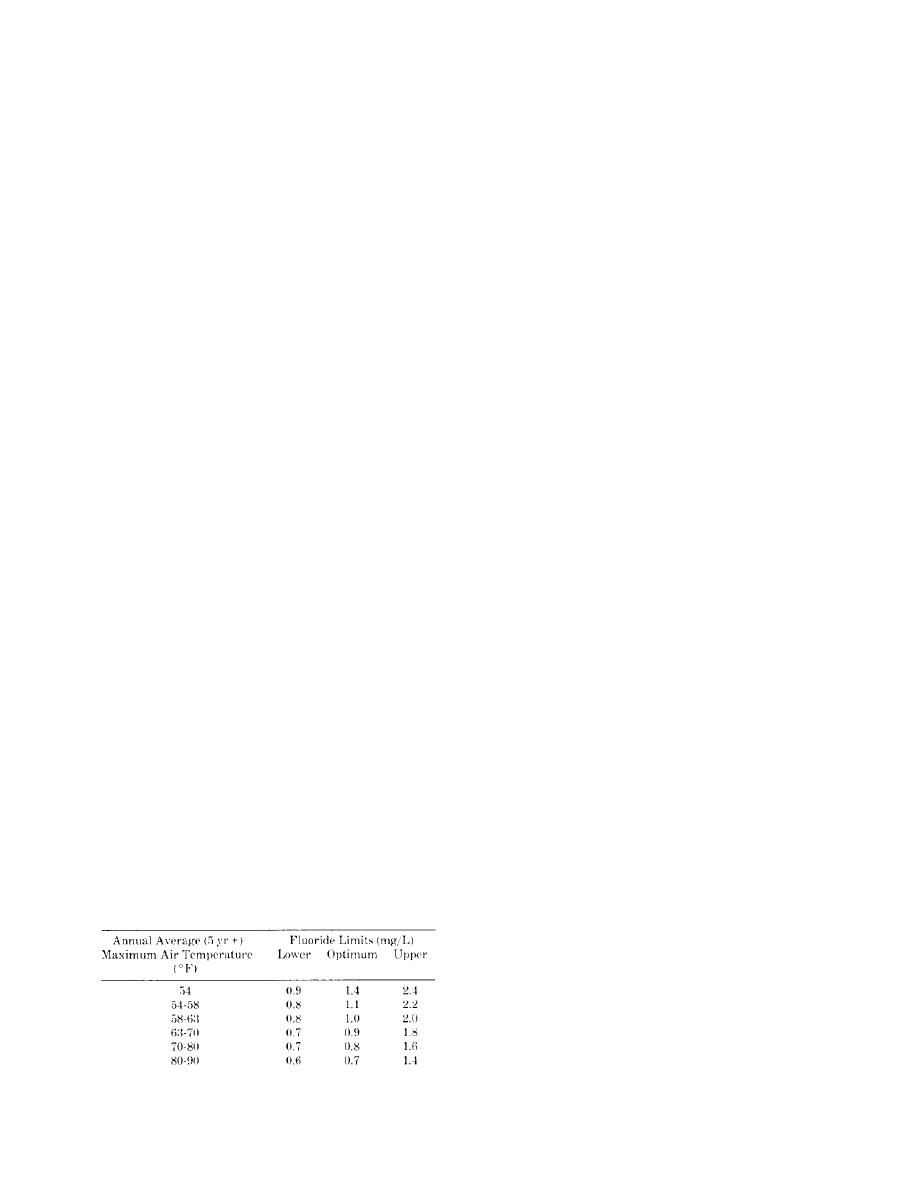

USPHS recommended fluoride limits to the annual

sensitive to viscosity effects and the multipliers from

average air temperature at the design location. (See

figure 9-2 will be used in these cases (solids

TM 5-813-3/AFM 88-10, Vol.3, for specific guid-

concentrations >2000 mg/L). Another concern for

ance at military installations.)

any type of clarifier is the presence of density

4-4. Removal of minerals and organics.

currents induced by strong temperature differences

between the incoming fluid and the tank contents.

Ion exchange water softening is commonly used at

These currents will disrupt the settling process and

smaller installations with hard water. Lime-soda

are particularly critical for upflow clarifiers. If

softening is frequently used when the water is both

possible these units will be maintained at nearly

turbid and has a high hardness. Dissolved iron is

constant temperature and the incoming fluid

common in cold regions ground waters and can foul

adjusted to that same level.

zeolite and greensand ion exchange resins so that it

c. Filtration. Filtration is influenced by low tem-

must be removed prior to ion exchange processes.

perature since the head loss through the filter is

Aeration or chemical oxidation with chlorine have

proportional to viscosity. Mixed media filters will

been successful for precipitation of elemental iron.

provide a more efficient use of space in cold regions

However, iron/organic complexes are present in

facilities. The multiplier values from figure 9-1 will

many cold regions groundwaters. Ozone has been

be used to adjust filtration efficiency. Backwashing

shown to be effective in treating such waters. Ozone

of filters is also affected since power for pumping

and carbon adsorption are very effective for color

will vary with temperature, due to the increased

and organics removal.

water viscosity. The minimum upflow velocities will

4-5. Treatment of brackish and saline

be reduced because of the increased fluid density at

waters.

low temperature.

d. Disinfection. TM 5-813-3/AFM 88-10, Vol.

Distillation, reverse osmosis and freezing have all

3, should be consulted for basic criteria on

been used in the cold regions to reduce salt concen-

disinfection procedures, chlorine dosages and

trations to potable levels.

a. Distillation. Distillation is expensive, requiring

residuals. The solubility rate of chlorine decreases at

very low water temperatures, but for practical

relatively high skill levels to accomplish, and will be

purposes this will not occur at the dosage rates

considered only if other alternatives do not exist.

b. Reverse osmosis. Reverse osmosis (RO) is

commonly used. The effectiveness of chlorination is

hindered in cold water, and the exposure times must

temperature sensitive, with best results obtained

be increased in order to provide adequate

when water temperatures are in the range of 68 to

disinfection. Contact time of about 1 hour is

85 degrees F, and the cost is also high. Packaged

recommended for cold water below 40 degrees F.

reverse osmosis units are available from about 1000

e. Fluoridation. If fluoridation is practiced at

to 1,000,000 gallon/day capacity (gpd). Power

remote cold regions facilities, the U.S. Public Health

requirements are approximately one kilowatt-hour

Service (USPHS) recommends that the dosage

of power for each 100 gallons of potable water pro-

should be increased since the actual per capita

duced. These RO systems must be protected from

consumption of drinking water tends to be some-

freezing at all times, from the point of manufacture,

what less than in temperate locations. Fluoride con-

during storage and during use.

c. Freezing. This process takes advantage of nat-

centrations of about 1.4 mg/L are recommended for

the Arctic and Subarctic. Table 4-1 relates the

ural low temperatures to separate the saline brine

from the ice which is then melted (naturally in the

spring and summer) and used for water. Trenches

have been filled with brackish water, allowed to

freeze several feet deep, and then the remaining

liquid under the ice pumped out. Spray freezing

involves sprinkling brackish water through a nozzle

to form a large cone of ice, with the brine draining

away continuously during the winter. In a pilot-scale

test in Saskatchewan, chloride content was reduced

from 2000 mg/L to 500 mg/L in the melted ice. The

recovered water represented about 75 percent of the

volume sprayed.

4-2

Previous Page

Previous Page