TM 5-852-5/AFR 88-19, Volume 5

installed as individual units or combined with other

Standby units for critical equipment are essential

utility services in a utilidor. Above-ground utilidor

and are particularly important for emergency power

systems offer easier access for maintenance and

and for heating systems. Humidity is a critical factor

repair, and are cheaper to build where site condi-

in enclosed spaces and both high and low extremes

tions are poor. However, there are disadvantages.

can be experienced in arctic situations. Since natural

Above-ground units are exposed to extreme winter

humidity is extremely low due to the low winter

conditions and must have additional thermal pro-

temperatures, humidifiers (to maintain humidity at

tection (see chapter 12) as compared to a buried

about 30 percent) may be desirable in personnel

system. Above-ground systems are susceptible to

spaces. Very high humidity is experienced in pump

vandalism and traffic damage, they disrupt pedes-

stations and enclosed treatment works, and thus

trian and vehicle traffic patterns, and create snow

condensation may occur on cold surfaces causing

removal problems. In general, below-ground instal-

damage and inconvenience.

lation will be adopted wherever possible. In the

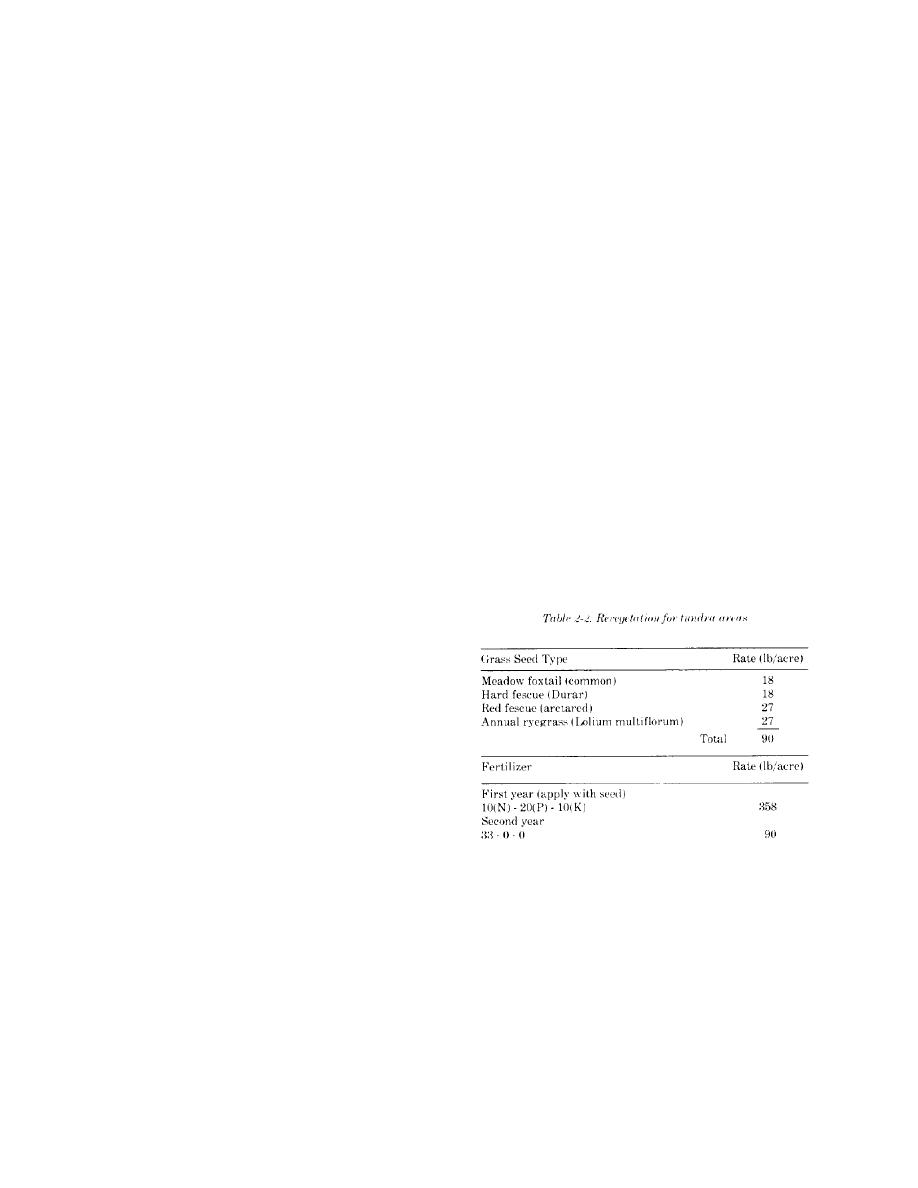

2-4. Revegetation.

Subarctic, an unfrozen zone may exist between the

maximum seasonal frost penetration and the top of

Areas excavated and backfilled for utility systems

the permafrost. This condition can also exist in the

must be revegetated to prevent erosion. A revegeta-

Arctic near lakes and rivers, and on slopes with

tion procedure is summarized in table 2-2 for tundra

southern exposure. Pipes buried in permafrost or in

areas. These grasses will die out in four to five years

the seasonal frost zone must not only be protected

but the natural vegetation will have developed by

from freezing but must also resist the structural

that time. The initial seeding and fertilization will

effects of heaving in the seasonal frost zone or

take place after the ice breaks up on local streams

thawing of permafrost. The terrain is relatively flat

but before mid-summer. As indicated in table 2-2, a

in much of the Arctic, and maintenance of the neces-

nitrogen-phosphorus-potassium (N, P, K) fertilizer

sary grades for gravity sewers in either the above-

will be applied with the initial seeding and then

ground or buried mode is difficult. Small pump

supplemental nitrogen at the beginning of the

stations, or pressure or vacuum sewer systems must

second growing season.

be used to overcome these constraints.

b. Network layout. A compact installation layout

will make a central heating plant practical. This will

reduce costs and energy consumption and also

reduce the risk of fire. Service lines from utility

mains to individual buildings are the main source of

freezing problems. Buildings will be as close to the

mains as possible with service lines 60 feet or less in

length. It is typical practice in temperate climates to

bury most utility lines in the streets. However, there

are thermal disadvantages to this practice in cold

regions since clearing the roads of snow will allow

greater frost penetration. Burying water and sewer

mains in the front or back yards of dwellings, and in

open areas where snow will not be removed, will

maintain warmer ground and pipe temperatures.

Installation layouts should not be designed with

dead-end streets. Dead-ends are difficult and

expensive to service with circulating water systems

and snow removal is more difficult. The largest

consumers of water will be located at the extremi-

ties of the distribution system, if possible.

2-3. Equipment.

For remote arctic installations the initial cost of

most utility equipment is not as important as its

reliability. A large inventory of critical spare parts is

recommended and standardization of equipment to

reduce the parts inventory will prove economical.

2-2

Previous Page

Previous Page