TM 5-852-4/AFM 88-19, Chap. 4

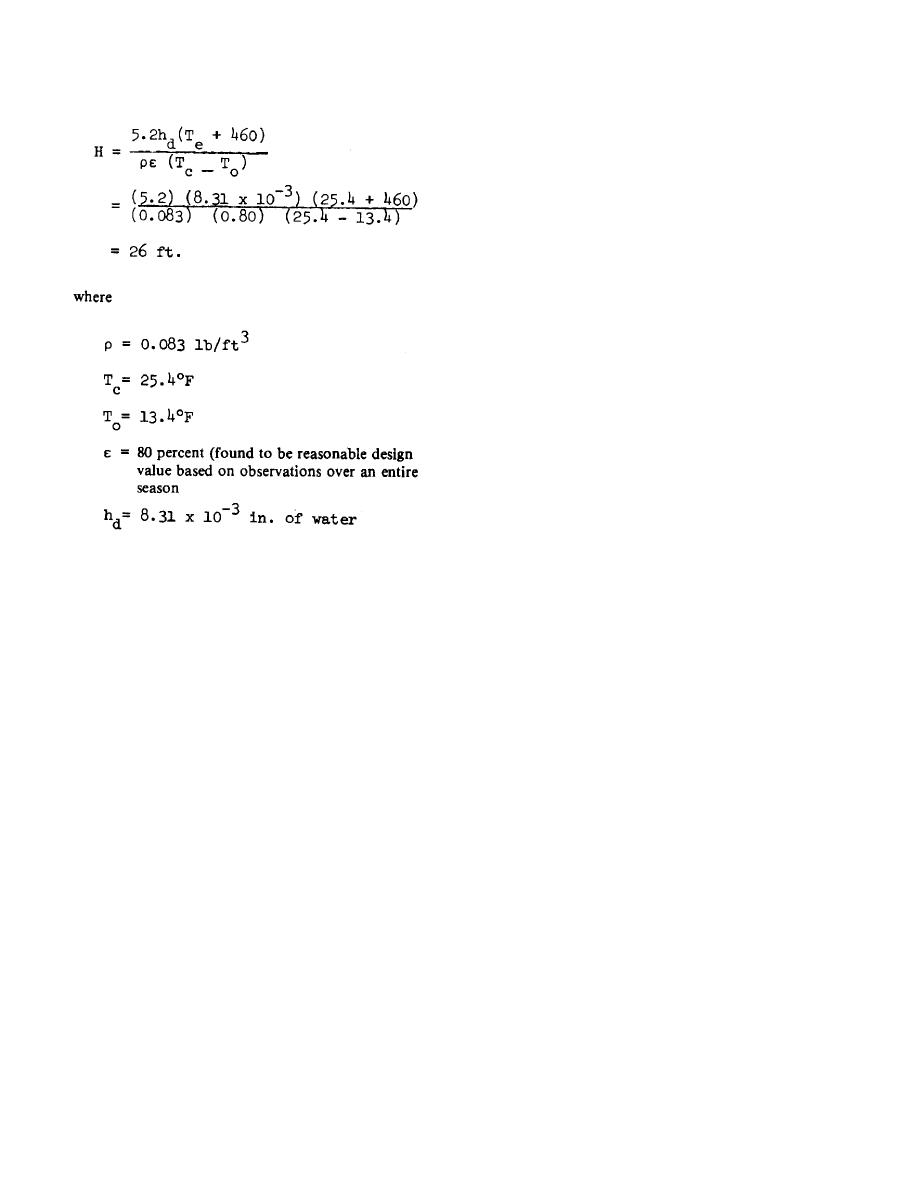

The stack height required to produce this draft head is

using a mechanical blower system to increase air

circulation (however, see discussion of disadvantages of

latter systems in (k) above. In order to minimize air flow

resistances and to avoid differences in heat removal

effectiveness between different parts of the foundation

duct system, the number of ducts connected together

through plenums into a single pair of intake and outlet

stacks should not exceed three to five. Thus, an

average foundation of this type may have numerous

intake and outlet stacks. A chamber extending the

length of the structure and open to the atmosphere along

its length as shown in figure 4-24 may provide an

acceptable alternative. Plenum chambers should be

designed so as to permit ready access to the ends of the

ducts for cleanout or other maintenance.

d. Foundation

insulation.

Foundation

insulation may be used to control heat flow for the

following objectives.

To control frost penetration and heave.

To reduce rates of thaw of permafrost and

settlement.

For heating economy.

For comfort.

To control condensation.

(1) The general properties of insulating

materials which are pertinent to construction under cold

climatic conditions have been reviewed in paragraph 2-

6d. Insulation used in foundations must satisfy the

If the stack height is too high for the structure, a

following performance criteria:

greater thickness of foundation insulation could be used.

Provide required thermal insulating properties.

In this example the effect of increasing the insulation

Provide adequate bearing capacity for static and

thickness by one-half would result in lowering the stack

dynamic loads which may be imposed.

height by five-eighths.

Resist loss of thermal insulating properties and

The first approximated stack height is next

bearing capacity with time under the effects

incorporated in the calculation of the length of straight

of moisture, ice and cyclic freeze thaw.

duct l S, and the newly obtained le is used to recalculate

(2) Insulation can reduce quantity of heat

flow but cannot prevent it entirely. Insulation should not

stack height is found to be 26.5 feet.

be depended upon by itself to prevent thaw of permafrost

The stack height is an important variable as an

under a continuously heated building or to prevent frost

increase in stack height will increase the duct airflow.

penetration under a continuously refrigerated warehouse

Circulation of air through the ducts results from a density

or other structure.

difference between the air inside the duct and that

(3) Where comfort is involved, as in

outside the building; a pressure reduction at the outlet

quarters buildings, the insulation thickness should not be

end due to the stack effect; a positive pressure heat at

less than that required to maintain floor surface

the inlet end when wind blows directly into the intake

temperature at satisfactory comfort levels under design

stack opening; and a negative pressure head at the

minimum winter temperature conditions.

Floor

outlet when wind passes over the exhaust stack opening.

temperature must also be maintained above the dew

If reliance is placed upon wind-induced draft for part of

point of the interior air under these conditions; moist

the required winter cooling, minimum wind conditions

floors are not only unpleasant for personnel but may

should be assumed in order to assure freezeback even

present hazards of slipperiness or sanitation. Much of

in the least favorable winter. Vents should be cowled to

the problem of cold floor discomfort in cold regions

take advantage of any available velocity head provided

originates from cold air drainage from inadequately

by the wind and as previously noted should be positioned

insulated ceilings, exterior walls, windows and doors.

to minimize snow infiltration. If sufficient air cannot be

However, discomfort may be experienced even where

drawn through the ducts by natural draft, consideration

these factors are absent, such as in interior rooms,

may be given to such alternatives as placing, the exhaust

stacks at the center of the building with intakes both

sides, in order to reduce the effective duct length, or

4-45

Previous Page

Previous Page