CEMP-ET

TI 809-53

01 May 1999

CHAPTER 10

COPPER AND OTHER CRAFTED METALS

REFERENCE

CEGS 07610 (Copper Roof Systems)

10-1. COPPER AND OTHER CRAFTED METALS.

a. Overview. Copper, lead-coated copper, terne coated steel (lead-tin alloy), terne-coated

stainless steel (TCS), zinc, and lead roofing are more formable and ductile than steel and aluminum

panels and are generally used in crafted systems where hand forming and/or soldering is required (Table

10-1). Most are extremely durable with records of roofs in service for centuries. These metals tend to be

relatively soft and are used in nonstructural applications where solid roof decking is used. Copper metal

gradually changes from a bright metallic copper color to brown, and eventually green (patina). In areas of

low air pollution (sulfur), lead, lead-coated copper and TCS may suffer from a red coloration (lead oxide)

rather than the expected dark gray patina. Because of their high material costs and intensive labor

requirements early historical uses of these metal roof systems were in cathedrals and civic buildings.

Typically, small flat pans with folded edges are formed. Cleats engage the folded-over edge of the pan

and are nailed to the substrate. The adjacent panel with a folded-under edge engages the installed pan

concealing the installed clip (figure 10-1). On low-slopes the seams are soldered together for

waterproofness. Crafted metal roofings are generally shop-fabricated by the contractor for each specific

application rather than factory formed. However, some automatic pan formers and mechanical seamers

are also used. Copper roofs include locked and soldered flat seam, standing seam, batten seam, and

custom design.

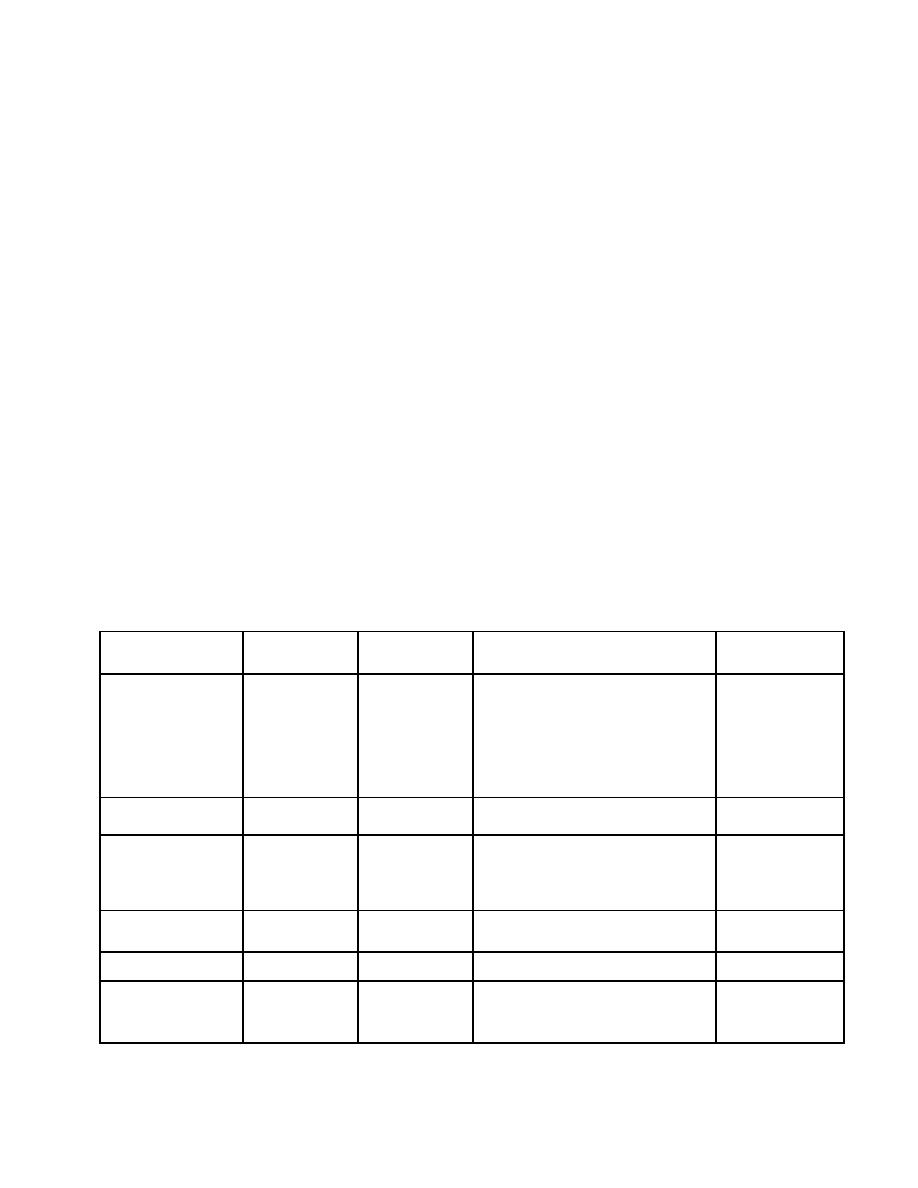

Table 10-1. Properties of Crafted Metals

Metal

Fastener

Ability to Solder,

Corrosion Resistance/Durability

Weathering

Compatibility

Weld, or Braze*

Characteristics of

Unfinished Material

Limestone, stucco, concrete, and other light

Copper

Copper, Brass, or

Solder-Yes

Brown tones

colored porous materials can show staining from

Stainless Steel

Weld-Yes

developing into a

moisture run-off from copper. Iron, galvanized

green-gray patina.

metal, and acidic solutions from some trees can

stain copper. Acid leaching from cedar roofing

can impede patina development and in severe

cases cause localized thinning of the copper.

Bitumen and fire-treated woods containing salt

are corrosive to copper. Copper should not be in

contact with steel or galvanized steel.

Used to avoid staining associated with copper.

Lead-Coated Copper

Copper, Brass, or

Solder-Yes

Dark gray to gray

However, lead oxide can cause staining (see

Stainless Steel

black.

"Lead" below).

Inert, atmospheric corrosion has little effect.

Lead

Copper, Brass, or

Solder-Yes

Dark gray to gray

Lead oxide can stain glass, stainless steel, and

Stainless Steel

Weld-Yes

black.

other materials. Lead is attacked by free lime

(found in fresh concrete). Lead can be stained

by rust from steel.

Do not nail through metal; use cleats. Avoid

Terne-Metal (Terne-

Stainless Steel

Dark gray.

Solder-Yes

contact with aluminum, copper or acidic

Cadmium Plated

Coated Carbon Steel)

materials. Must be painted.

or Galvanized

Does not stain.

Terne-Coated

Stainless Steel

Solder-Yes

Medium to dark gray.

Stainless Steel (TCS)

Not compatible with bituminous roofing materials.

Zinc

Galvanized or

Solder-Yes

Dark bluish gray.

Copper generates a corrosion compound that

Stainless Steel

attacks zinc. Sulfur dioxide inhibits the

development of zinc's carbonate film. Wood

preservatives can corrode zinc.

*When welding or brazing metal components, the gauge of the metal will affect the level of difficulty in achieving a proper weld (i.e.,

thicker materials are generally easier to weld or braze).

10-1

Previous Page

Previous Page