CEMP-E

TI 809-26

1 March 2000

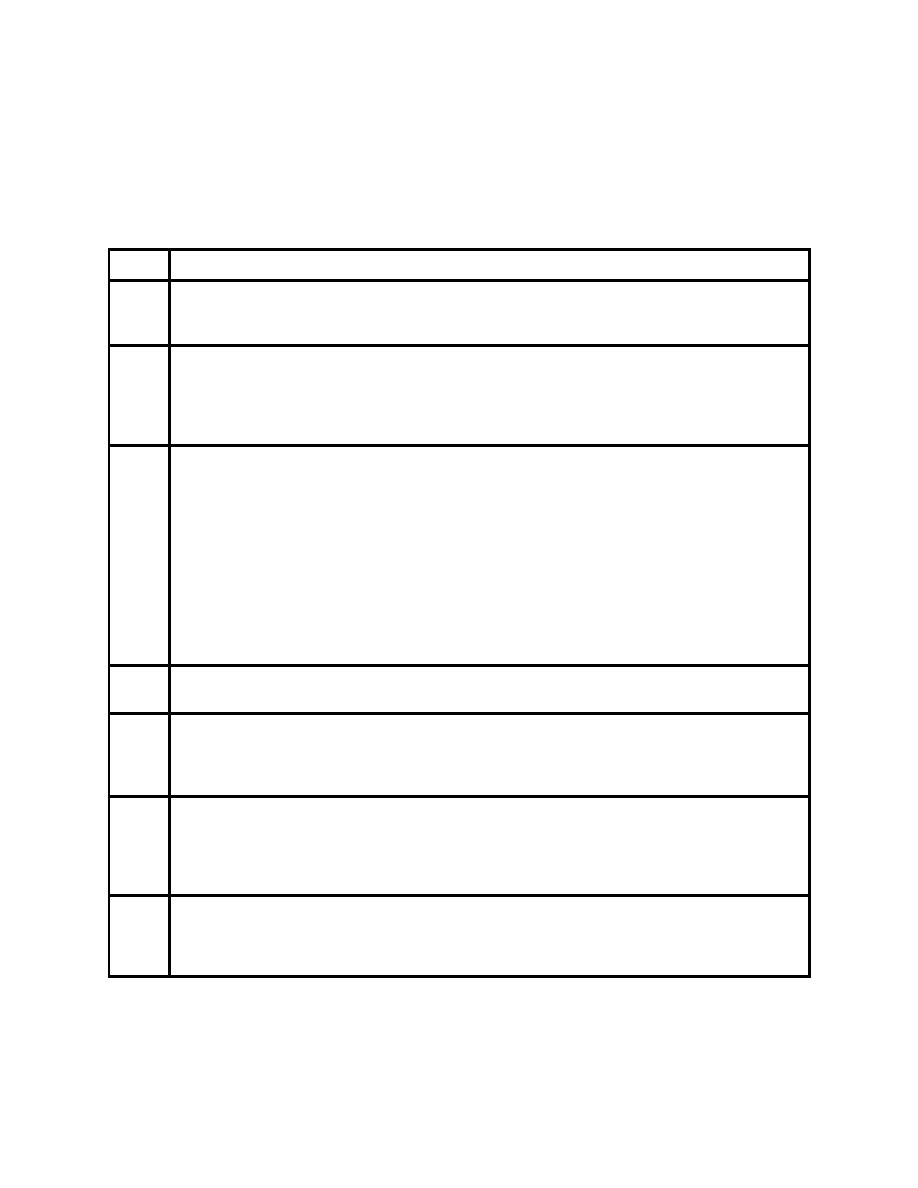

Table C-1. AWS A5.1 Classification System for Carbon Steel Electrodes for SMAW

Table

E XX YY M - 1 HZ R

E

Electrode

XX

Minimum tensile strength in units of 1 ksi (7 MPa)

60 = 60 ksi (420 MPa)

70 = 70 ksi (480 MPa)

Y

Generally, welding positions permitted for use, but may be additionally limited by

electrode diameter and class

1 = all positions (F, H, V, OH)

2 = F, H-fillets

4 = F, H, V-down, OH

Y

Type of covering

0 = high cellulose sodium (E6010)

0 = high iron oxide (E6020)

1 = high cellulose potassium

2 = high titania sodium

3 = high titania potassium

4 = iron powder, titania

5 = low hydrogen sodium

6 = low hydrogen potassium

7 = high iron oxide, iron powder

8 = low hydrogen potassium, iron powder (except E7018M)

9 = iron oxide titania potassium

M

If present, meets special Military specifications, and covering is low hydrogen, iron

powder

-1

If present, indicates improved notch toughness (see AWS A5.1, Table 3)

for E7016-1, average CVN of 27 J @ -46oC ( 20 ft-lbf @ -50oF)

for E7018-1, average CVN of 27 J @ -46oC ( 20 ft-lbf @ -50oF)

for E7024-1, average CVN of 27 J @ -18oC ( 20 ft-lbf @ -0oF)

HZ

Optional supplemental diffusible hydrogen designator

H16 = maximum 16 mL / 100 g deposited weld metal

H8 = maximum 8 mL / 100 g deposited weld metal

H4 = maximum 4 mL / 100 g deposited weld metal

(note: E7018M meets H4 requirements, but the H4 designation is not used)

R

If present, indicates electrode has lower moisture content and meets absorbed

moisture test requirements

(note: E7018M must meet more stringent requirements, but the R designation is

not used)

C-4

Previous Page

Previous Page