CEMP-E

TI 809-26

1 March 2000

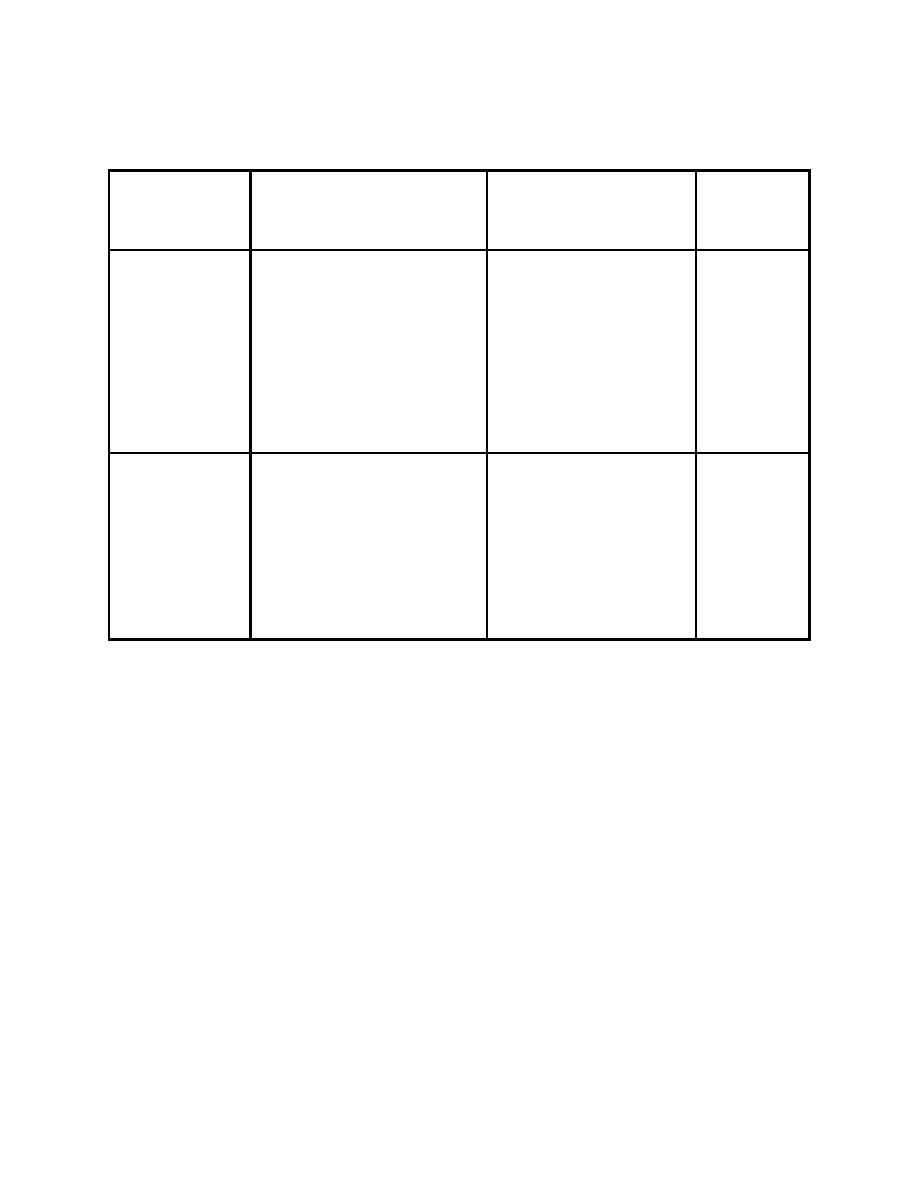

Minimum

Material Thickness of

Preheat and

Category

Structural Steel

Thickest Part at Point of

Interpass

Welding

Temperature

3 to 19 mm (incl.)

10oC (50oF)

(1/8 to 3/4 in.)

C

over 19 to 38.1 mm (incl.)

66oC (150oF)

Shapes and Plates

When using

(3/4 to 1-1/2 in.)

A572, grades 60 and 65

SMAW with low-

A709, grade 70W2

over 38.1 to 63.5 mm

107oC

A852, grades 702

electrodes, or

(incl.)

(225oF)

A913, grades 60 and 65

FCAW, GMAW or

(1-1/2 to 2-1/2 in.)

SAW

over 63.5 mm

150oC

(2-1/2 in.)

(300oF)

D

When using

SMAW with low-

Shapes and Plates

electrodes, or

A913, Grades 50, 60, and

all thicknesses

0oC (32oF)1

FCAW, GMAW or

65

SAW, with

electrodes of

class H8 or

lower

- If the steel is below 0oC (32oF), the steel, in the vicinity of welding, must be raised to and

1

maintained at a minimum temperature of 21oC (70oF) prior to and during welding.

- Maximum preheat and interpass temperature of 200oC (400oF) for thicknesses up to 40 mm

2

(1-1/2 inches) inclusive, and 230oC (450oF) for thickness greater than 40 mm (1-1/2 inches).

3-4

Previous Page

Previous Page