CEMP-E

TI 809-26

1 March 2000

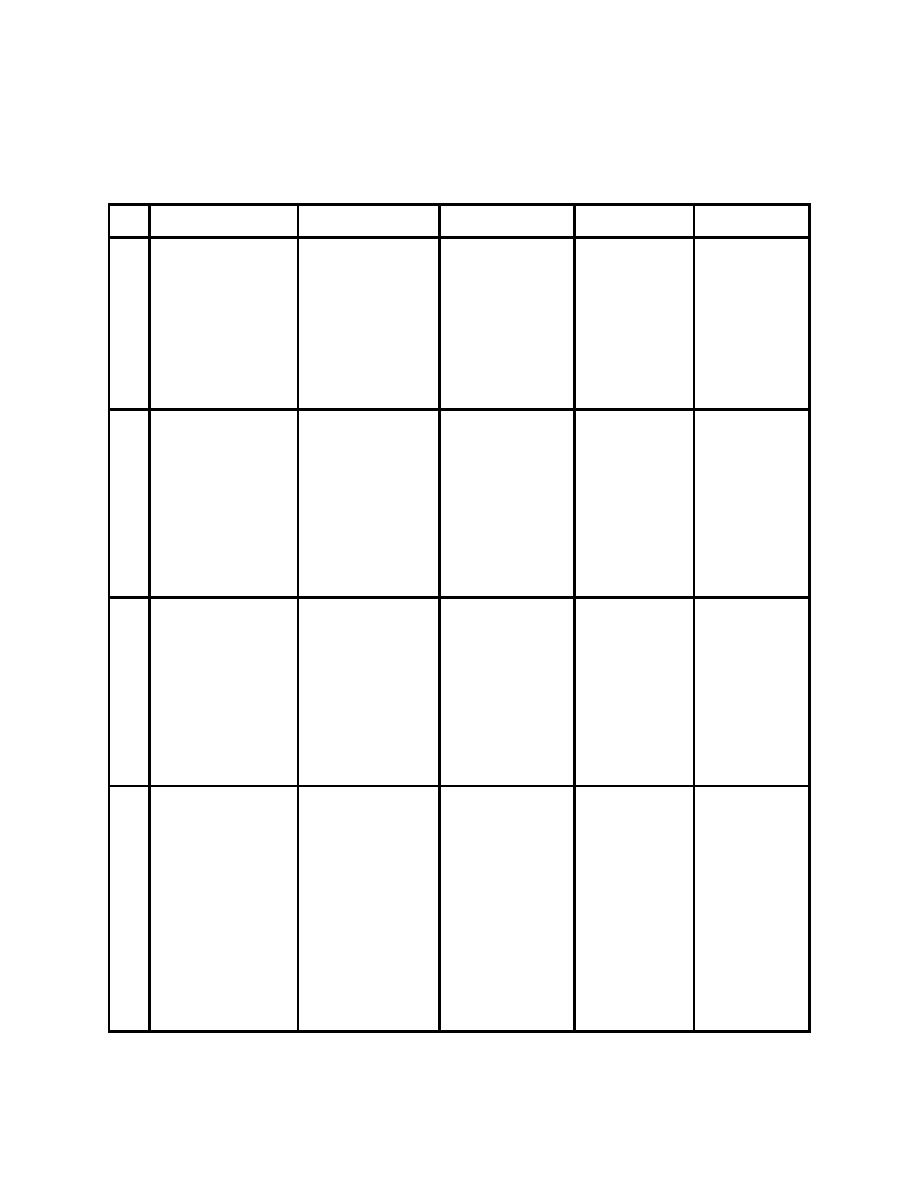

Table 8-2. Guidelines for Selecting Inspection Techniques

Table

VT

VT

PT

MT

UT

RT

E

Pocket

Fluorescent or

Wet or dry iron

Ultrasonic

X-ray or

q

magnifier,

visible

particles, or

units and

gamma-ray;

u

flashlight, weld

penetration

fluorescent;

probes;

film

i

gauges, scale,

liquids and

special power

reference

processing

p

t

etc.

developers;

source;

patterns

and viewing

m

ultraviolet light

ultraviolet light

equipment

e

for fluorescent

for fluorescent

n

dyes

particles

t

D

Weld

Discontinuities

Surface and

Can locate

Most internal

e

preparation, fit-

open to the

near surface

all internal

discontinuiti

t

up, cleanliness,

surface only

discontinuities:

discontinuiti

es; limited

e

roughness,

cracks;

es located by

by direction

c

t

spatter,

porosity; slag

other

of

i

undercut,

methods, as

discontinuity

o

overlap, weld

well as small

n

contour and size

discontinuiti

es

A

Easy to use; fast;

Detects small

Detects

Extremely

Provides

d

inexpensive;

surface

discontinuities

sensitive;

permanent

v

usable at all

imperfections;

not visible to

complex

record of

a

stages of

easy

the naked eye;

weldments

surface and

n

t

production

application;

useful for

restrict

internal

a

inexpensive;

checking edges

usage

discontinuiti

g

low cost

before welding;

es

e

no size

s

limitations

For surface

Time-

Surface

Highly skilled

Usually not

conditions only;

consuming; not

roughness may

interpreter

suitable for

L

dependent on

permanent

distort

required; not

fillet weld or

i

subjective

magnetic field;

permanent

T-joint

m

i

opinion of

not permanent

inspection;

t

inspector

film

a

exposure

t

and

i

o

processing

n

critical; slow

s

and

expensive

8-11

Previous Page

Previous Page