TM 5-809-3/NAVFAC DM-2.9/AFM 88-3, Chap. 3

which, in conjunction with the pathlength, gives a

pulse velocity as described previously. The simplest

simple indication of pulse velocity. The pulse

way to utilize mechanical wave transmission data is

velocity can, to various degrees of accuracy, be

to simply record the arrival time and the pathlength

correlated with material properties. In addition,

and calculate an average velocity for the pulse. The

sonic techniques can be used to locate material

recorded data should then be plotted in some

flaws, however, the long wave length that makes a

understandable format. Two dimensional contours

sonic pulse appropriate for testing long expanses of

or three dimensional surface plots are

brick work also increases the minimum size flaw

recommended for direct tests, and x-y plots are

that can be detected.

recommended for indirect tests. Figure 10-8 plots

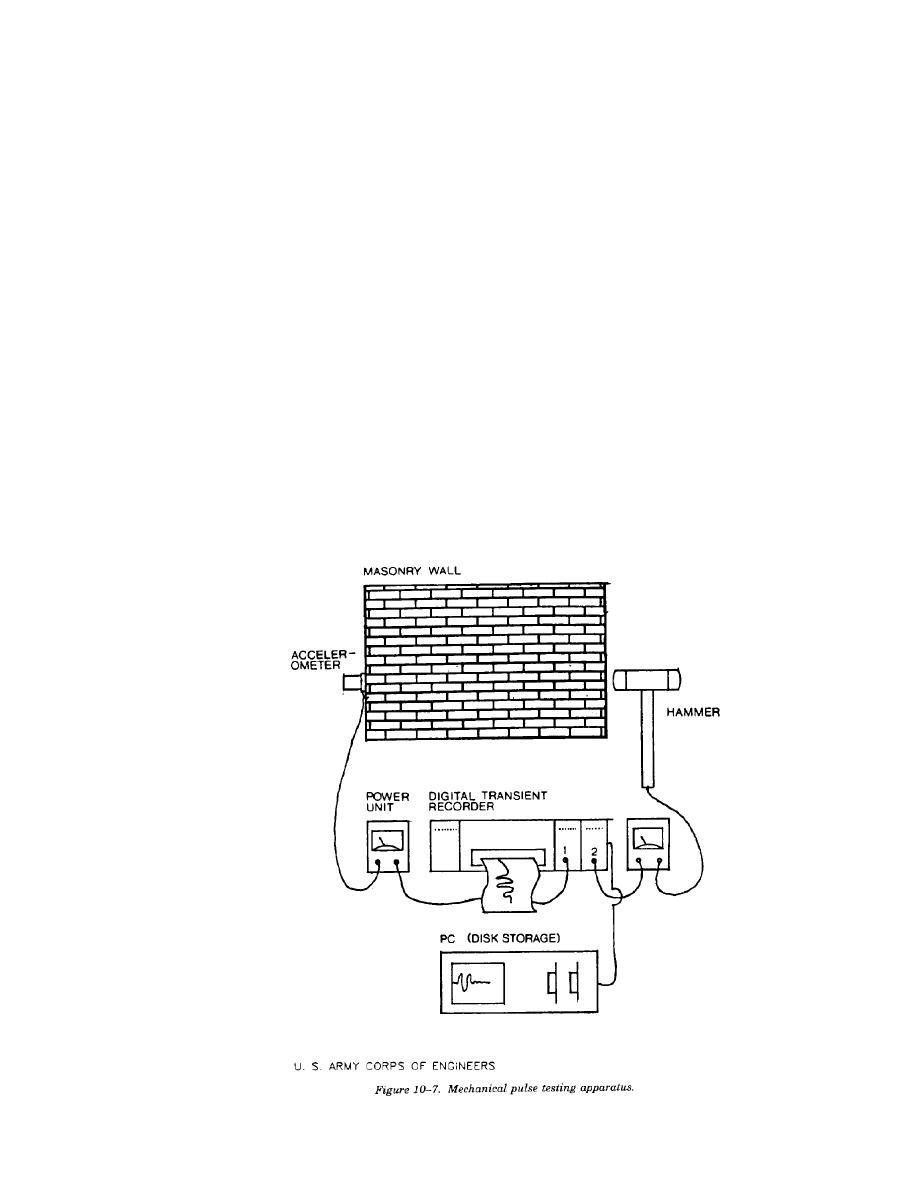

(1) Equipment. The basic equipment used

the pulse path length against the arrival time for an

for conducting mechanical pulse tests includes a 3

indirect mechanical pulse test. The presence of a

pound modally tuned hammer and an accelerome-

distinct flaw causes a noticeable break in the

ter. Unlike the ultrasonic test equipment, there is

velocity line.

(3) Application. The mechanical pulse tech-

no digital readout of travel time with this equip-

ment, so the signal must be recorded or displayed

nique is best suited to the task of locating flaws and

on an external device. A digital transient recorder

discontinuities such as missing mortar joints and

can be used to record both the hammer input signal

large cracks and establishing relative quality of

and the accelerometer output signals. The signals

masonry from one location to another. Indirect

can then be saved on floppy disks through a

tests are useful for determining the average velocity

portable computer. The testing apparatus is shown

through a single outer wythe of masonry, and for

in figure 10-7. Alternatively, an oscilloscope may

locating flaws in the outer wythes. Direct tests are

be used to measure travel time.

able to locate flaws and voids in interior wythes

(2) Use. Test results for mechanical pulse

and collar joints. The mechanical pulse technique is

tests are much the same as those for ultrasonic

superior to the ultrasonic system for flaw detection

10-9

Previous Page

Previous Page