CEMP-E

TI 809-02

1 September 1999

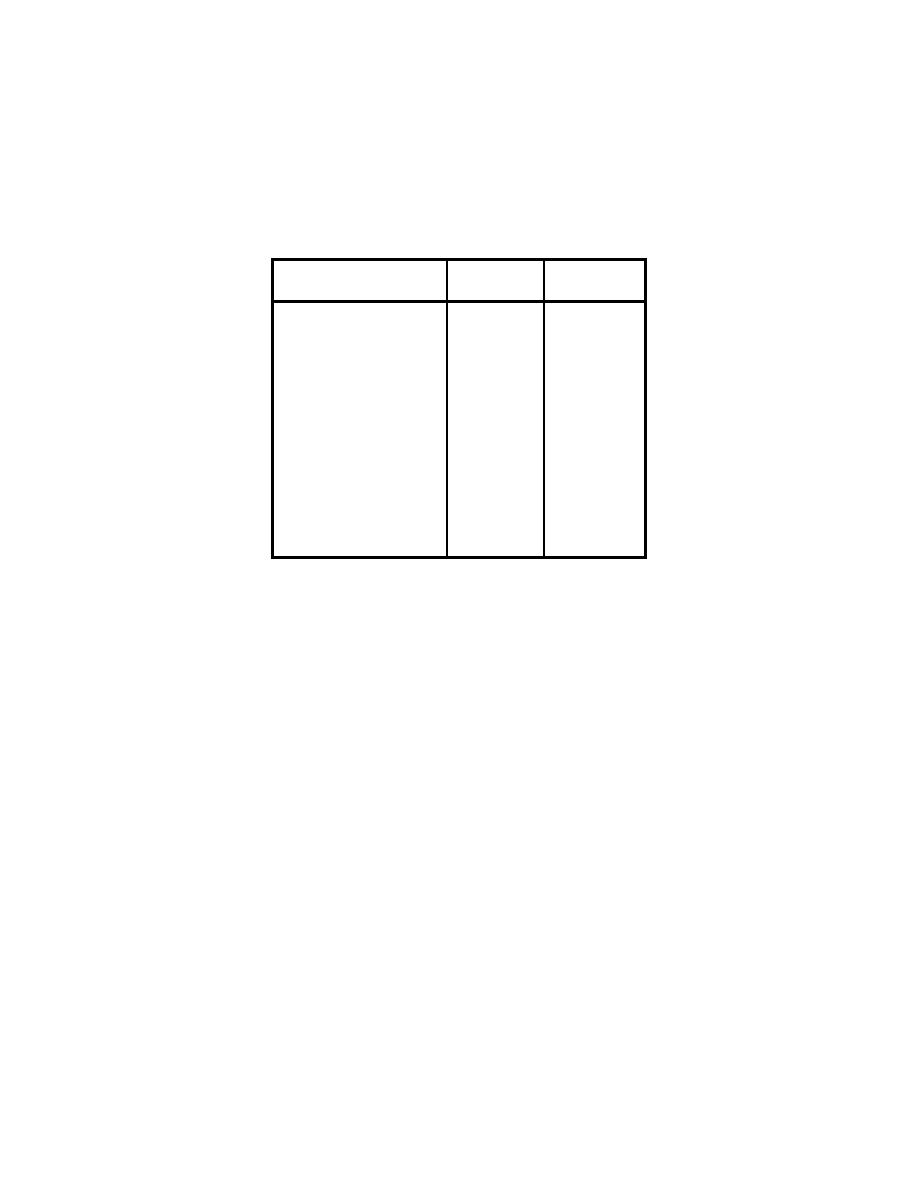

Table 4-2. Recommended Air Contents for Frost-resistant Concrete

(From ACI Committee 201 Report)

Average air content %

Nominal Maximum

Severe

Moderate

Aggregate Size

Exposure Exposure

10 mm (3/8 inch)

7 1/2

6

12 mm (1/2 inch)

7

5 1/2

19 mm (3/4 inch)

6

5

38 mm (1 1/2 inch)

5

4 1/2

75 mm (3 inch)

4 1/2

3 1/2

150 mm (6 inch)

4

3

(2) Corrosion Protection. Corrosion protection is accomplished primarily by providing a

sufficient thickness of concrete cover over reinforcing steel and other embedded items. A

complete discussion of corrosion causes and preventive measures can be found in the ACI

Committee 201 Report, "Guide to Durable Concrete," and in ACI Committee 222 Report,

"Corrosion of Metals in Concrete." For normal exposure conditions, or those conditions where

the concrete is not exposed to chlorides, the minimum concrete cover protection specified in

ACI 318 will be provided. Concrete cover requirements for severe exposure conditions is

covered in Chapter 12.

b. Crack Control. Cracking in concrete occurs mainly when volume changes due to

drying shrinkage and temperature effects are restrained. Cracking can also occur due to

externally applied loads. Cracks indicate a major structural problem, or a serviceability

problem. Reinforcing steel exposed to moisture and air can corrode. The corroded steel has a

volume several times that of the parent material. Cracking and spalling occurs due to the

expansion of the steel as it corrodes. A discussion of the factors that cause cracking in

concrete and measures that can be used to control cracking are provided in the ACI

Committee 224 Report, "Control of Cracking in Concrete Structures." Cracking can be

controlled by providing adequate temperature and shrinkage reinforcement, by reducing steel

stresses at service load conditions, and by reducing restraint through the use of joints.

Tolerable crack widths for reinforced concrete under various exposure conditions are provided

in Table 4-3.

4-3

Previous Page

Previous Page