UFC 3-280-04

17 DEC 2003

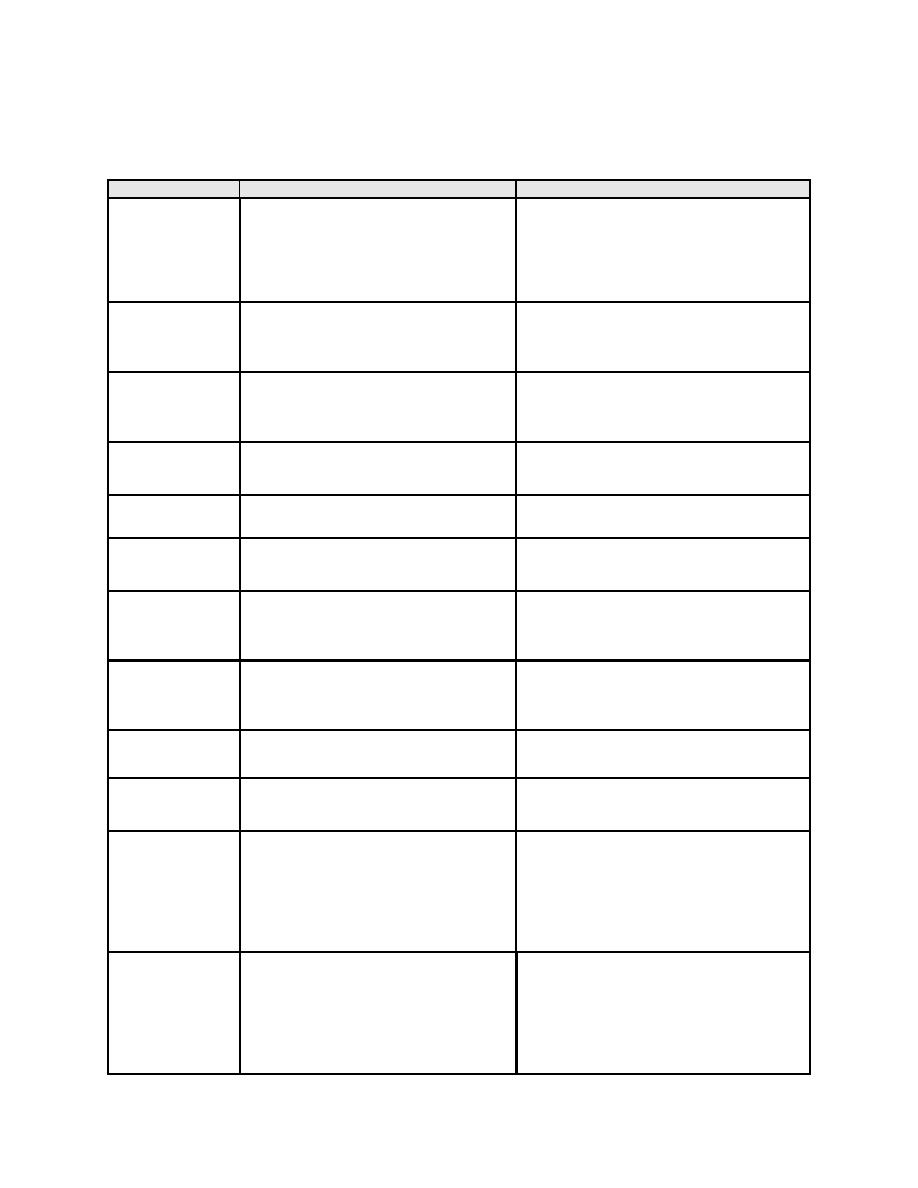

Table 6-1. Commonly Encountered O&M Problems

Description

Control Measures

Turbidity

Unacceptable levels of turbidity in efflu-

Pre-treat with chemicals or polymers, or

breakthrough

ent before terminal head loss is

both, upstream of the filter bed.

reached.

More frequent backwashing.

Reduce solids loading through pre-

filtration solids removal, such as

sedimentation.

Mudball

Masses of solids, dirt, and media, the

Auxiliary washing processes (e.g., air

formation

mudballs sink into the filter bed,

scour, surface wash) with, or followed

reducing the effectiveness of filtering

by, water wash

and backwash.

Buildup of grease

Oil or grease emulsifying within the

Air and surface wash usually help.

and oil

bed.

May be necessary to install washing

system using special solutions.

Pre-treat for oil and grease.

Carbonate

Carbonate buildup on media after lime

Acid rinse or, for small systems, replace

buildup

media.

Influent pH adjustment.

Cracks /

Develop when filter bed is not cleaned

Adequate backwash and scour.

contraction

properly.

Loss of media

Loss during backwashing or through

Correct placement, sizing of wash water

underdrain system.

troughs, and underdrain system.

Correct backwash flow or pressure.

Air binding

Gases coming out of solution in the

Backwash at terminal head loss no

water because of negative heads.

greater than the depth of submergence

of the top of the filter media or increase

submergence.

Gravel mounding

Support gravel disruption during

Overlay gravel support layer with layer of

backwash.

high density material, such as ilmenite or

garnet.

Correct backwash flow rate or pressure.

Excessive head

Filter element clogged without alarm

Change elements and check alarm for

loss

sounding.

malfunction.

Excessive

Filter element damaged.

Change element more frequently and look

turbidity without

for waste stream components that could

head loss

damage filter fabric.

Excessive filter

Filtration system improperly sized for

Increase the number of filter elements

element

waste stream.

operating in parallel.

changeout

If allowed by the application, increase the

cartridge removal rating so that fewer

solids are retained.

Influent pretreatment to reduce solids

loading.

Biofouling

The growth of a biologic mass, such as

Chemical pretreatment at the source or

algae, either within the waste stream or

within the treatment process using

the treatment process, that creates a

hydrogen peroxide or chlorination.

solids loading of a concentration and

Identify the factors contributing to bio-

character that cannot be effectively

mass growth (e.g., heat, excessive

filtered.

holding time, high organics in the waste

stream) and eliminate them.

6-5

Previous Page

Previous Page