UFC 3-280-04

17 DEC 2003

10200 microns. Bag filters can remove particles down to 5 microns and, on occasion

and depending on waste stream characteristics, they have been used to filter particles

in the 13 micron range. They have less filter media surface area than cartridge filters of

similar dimensions but are often better at handling gelatinous materials that may clog

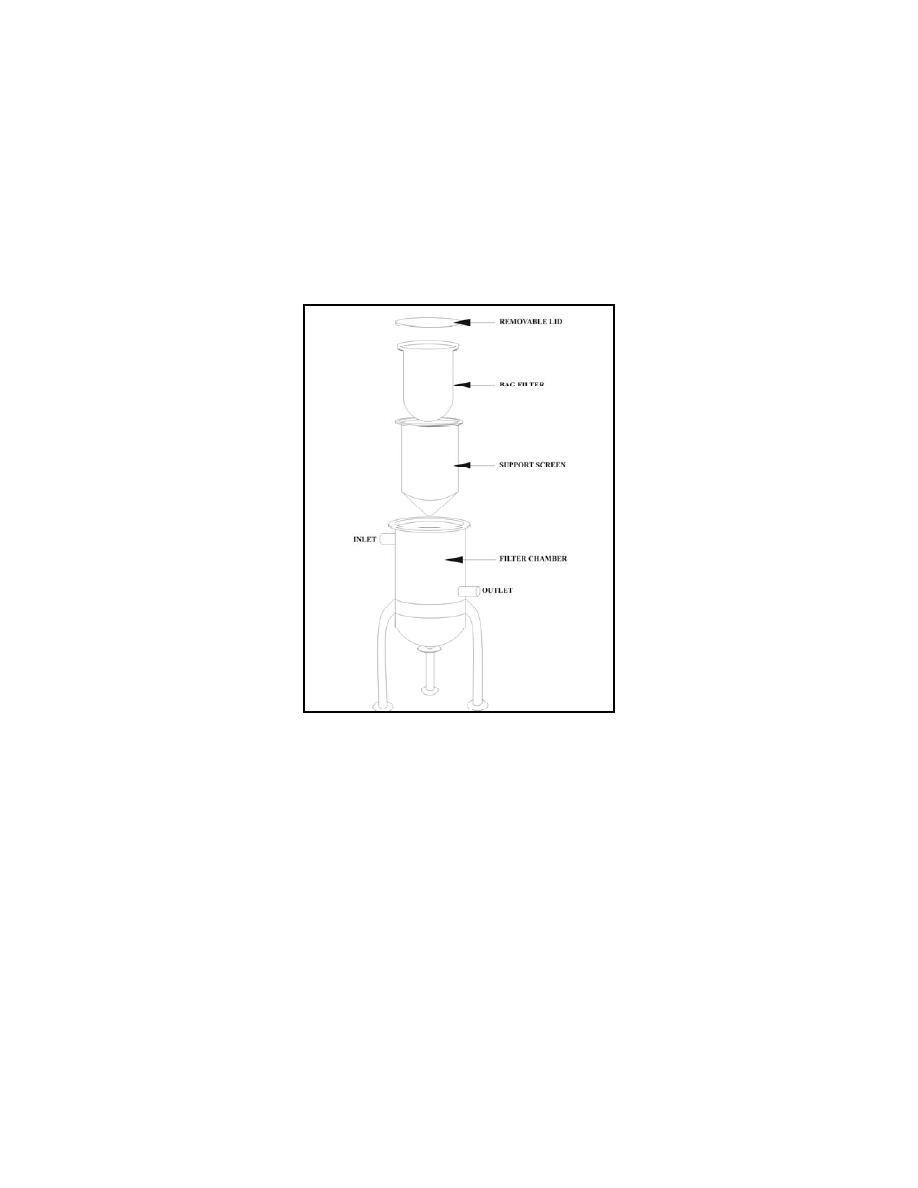

granular media or bridge across pleated cartridge media. A typical bag filter housing is

shown in Figure 5-11.

Figure 5-11. Typical Bag Filter Housing

5-4.2

Media

5-4.2.1 Type of Media. The types of media used to manufacture bag filters are simi-

lar to those used to manufacture cartridge filters and include cotton, nylon, polypropyl-

ene, polyester, Teflon, glass, and saran. Material such as ceramic and metals are not

used for manufacturing of bag filters, but these materials may be used in bag filter re-

strainers, fittings, and housings. Selection of the media, as with cartridge filters, de-

pends on waste stream characteristics, filter operating conditions, and desired effluent

quality. Similar to cartridge filters, bag filters can also be composed of several medium

types. It is important to ascertain the compatibility of each filter medium with the par-

ticular waste stream. Refer to Tables 5-6 and 5-7 for filter media compatibility with vari-

ous waste streams.

5-4.2.2 Configuration. There are two basic bag filtration system designs--open and

closed. Open systems are most often used in straining liquid slurries or dispersions

where particles are screened by the filter fabric while the slurry or dispersion passes

through the filter media. The closed design has advantages in that operations staff are

5-39

Previous Page

Previous Page