UFC 3-280-04

17 DEC 2003

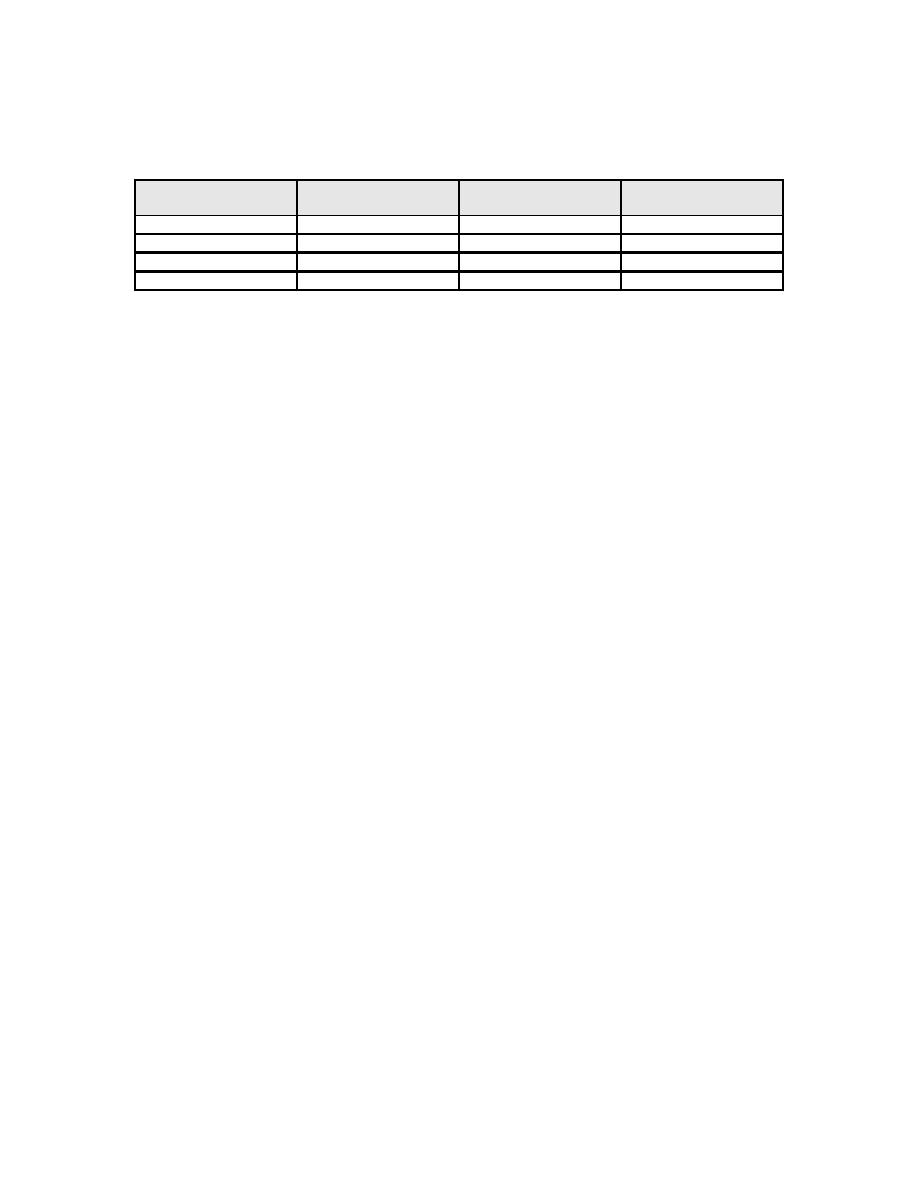

Table 5-2. Typical Properties of Filter Media Material

Material

Density

Sphericity

Porosity

g/cm3 (lb/ft3)

Silica sand

2.62.65 (162165)

0.70.8

0.420.47

Anthracite

1.451.73 (90106)

0.460.60

0.560.60

GAC

1.31.5 (8193)

0.75

0.50

Garnet

3.64.2 (224262)

0.60

0.450.55

5-1.2.4 Media Shape. Grain shape is important because it affects the backwash flow

requirements for the media, the fixed bed porosity, and the head loss during filtration.

The measure of grain shape for granular media filtration is sphericity. It is defined as the

ratio of the surface area of an equal volume sphere (diameter of deq) to the surface of

the grain. The sphericity of filter media can be determined by measuring the pressure

drop through a sample and calculating the sphericity using the Carmen-Kozeny or Egun

equations for flow through porous media. This requires determining the equivalent

spherical diameter and the porosity of the sample first, so that the only unknown is

sphericity. Materials that are more angular, such as anthracite, have lower sphericity.

Typical values are presented in Table 5-2.

5-1.2.5 Fixed Bed Porosity. The fixed bed porosity of a granular media filter is de-

fined as the ratio of the void volume of the bed to the total bed volume and is expressed

as a decimal fraction. Fixed bed porosity is affected by the sphericity of the media;

those with lower sphericity will have a higher fixed bed porosity. Porosity is determined

by placing a media sample of known mass and density in a fixed diameter, transparent

cylinder. The depth of the sample in the cylinder times the cylinder area establishes the

total bed volume. The media volume is calculated by dividing the mass of the sample by

the density of the media. By subtracting the media volume from the total bed volume,

the void volume is determined. The porosity is then calculated as the ratio of the void

volume to the total bed volume of the sample.

5-1.2.6 Typical Media Properties and Design Standards. Some typically measured

values of density, sphericity, and porosity of different types of filter media are shown in

Table 5-2. Differences in the densities of the various materials are what permit their use

in dual media applications. Larger sizes of the lower density media--anthracite and

granular activated carbon--are used as a cap material. These lower density media also

have higher values of porosity, which will allow floc penetration. The larger media size

and greater porosity will typically result in better deep bed filtration.

5-1.2.6.1 Silica sand is the most common filtration media. Sand filters have historically

been used alone or in combination with other media. Silica sand is both economical and

fine-grained, which results in a satisfactory quality of effluent. But, single media sand

filters generally have short filter runs because the particles become trapped in the fine

grains at the top of the medium, quickly increasing head loss to an unacceptable level.

To overcome this, sands of varying sizes may be used in an unstratified bed. Alterna-

tively, coarser materials have been used in combination with fine-grained sand, where

the lighter, coarser materials will be found at the influent side of the bed. The most

5-5

Previous Page

Previous Page