UFC 3-280-03

23 JULY 2003

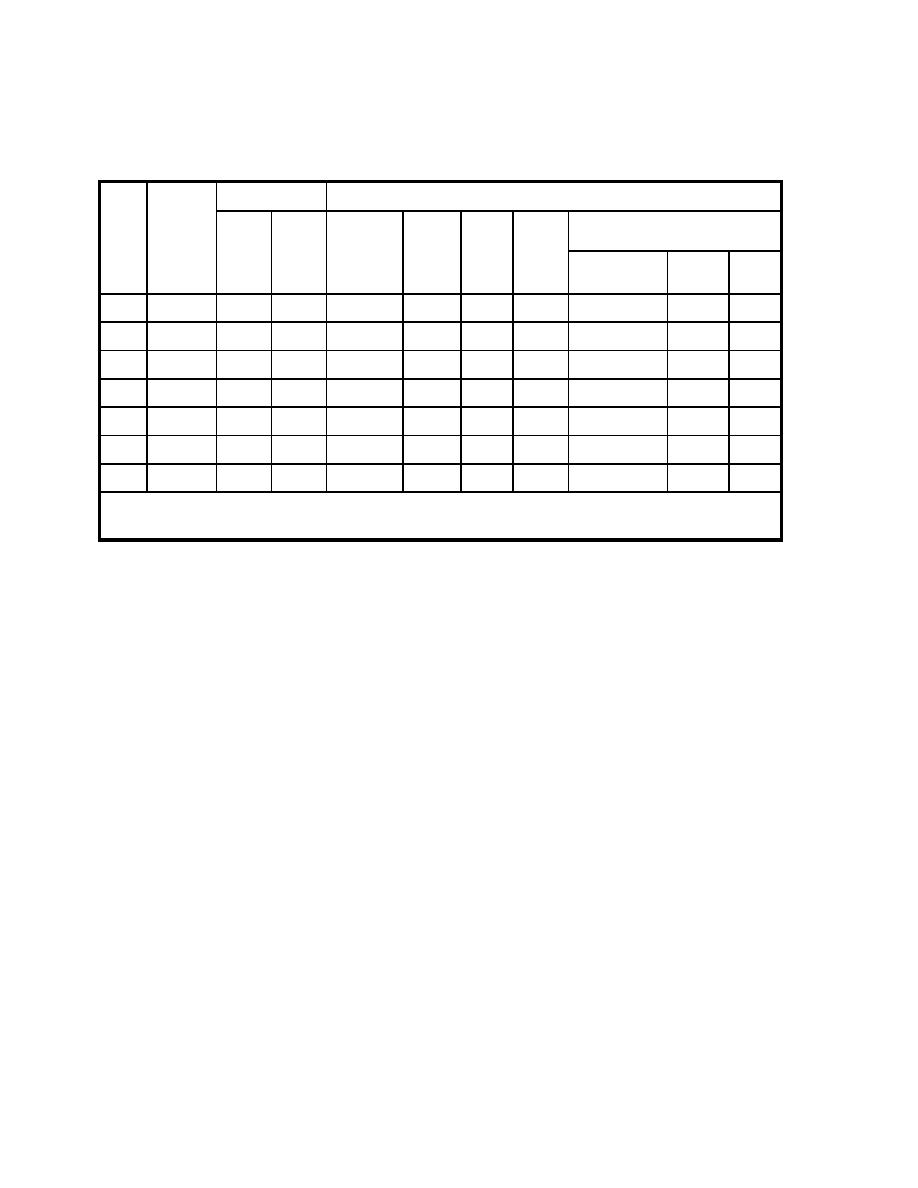

Table 2-8. Typical filter press plate sizes and weights.

Plate chamber

Press dimensions and weights (based on 32-mm cake thickness)

3

capacity (m )

Plate

25-mm 32-mm

Plate

filtration

Weight (kg)

(1-in.)

(1.25-

size

area per

Number of

Length

Width

Height

thick

in.)

(mm)

chamber

Cast

chambers

(mm)

(mm)

(mm)

cake

thick

2

(m )

Polypropylene

Rubber

iron

cake

plate

plate

plate

20

2200

1210

1900

2240

500

0.288

0.0039

0.0048

1250

1500

40

3850

1700

2760

1760

20

2800

1470

2300

2804

630

0.484

0.006

0.0075

1350

1500

40

4080

2260

3520

4153

20

3440

2570

4020

4760

800

0.889

0.0112

0.0135

1700

1550

60

6000

3420

7620

9760

30

4660

5060

8490

11,870

1000

1.51

0.0192

0.0224

2000

1500

90

8620

7130

17,200

27,100

50

6610

11,350

18,700

27,060

1200

2.1

0.0284

0.035

2200

1800

100

8210

14,150

28,700

45,260

60

7980

16,600

30,000

45,160

1500

3.5

0.045

0.056

2600

1850

120

12,640

22,260

49,000

78,780

2000

5.66

0.0865

0.104

150

17,430

3400

2135

NR

200,000

NR

NR = not reported

Source: Rushton (1982)

Conversions: 1 mm = 0.039 in.; 1 m2 = 10.8 ft2; 1 m3 = 35.3 ft3; 1 kg =2.2 lb.

2-4.5.4 Closing Mechanism. The closing mechanism either hydraulically or

electromechanically closes the plates and maintains the force to hold the plates

constant during the filter cycle period. The hydraulic closing mechanism can either be

manually operated by a jack or automatically controlled by a hydraulic ram and power

pack. The electromechanical mechanism typically consists of a twin or single screw and

electric gear motor. These systems can be equipped with automatic controls to maintain

a constant closing force to compensate for varying sludge feed pressure increases,

compression of the filter cloth and plates, and expansion and contraction of construction

materials with temperature changes.

2-4.5.5 Plate Shifter. Plates can be shifted manually or automatically to remove the

sludge cake after the filter cycle is complete. The typical shifting mechanism is a

semiautomatic or automatic device that works on the principle of an endless chain or

reciprocating bar. These mechanisms involve pawls attached to a chain or bar that

engage with the plate at the end of the plate pack and slide this plate along the plate

support to a distance of 2 to 3 feet, allowing the sludge cake to be discharged. This

process continues for each successive plate until all the plates have been separated

and the filter cake is removed.

2-4.5.6 Optional Equipment. Optional equipment that is typically provided to ensure

safe and successful performance includes safety guards, light curtains, drip trays, and

cake-breaking cables or bars.

2-4.5.6.1 Safety Guards. A fixed guard is one type of safety feature for smaller

presses where it is possible to designate operating and non-operating sides of the

press. Fixed guards typically consist of a metal screen mounted on the non-operating

2-43

Previous Page

Previous Page