UFC 3-270-07

12 August 2002

2-2.4.3.8 Standing water in the crater must be pumped out, if possible.

2-2.4.3.9 Any reinforcing material protruding from the original pavement must be cut off

and removed.

2-2.4.3.10 Backfill the crater with useable debris and level to exactly 711 millimeters

(28 inches) below the original pavement surface.

2-2.4.3.11 Backfill material must be compacted to a minimum 4 CBR.

2-2.4.3.12 Install a 304-millimeter (12-inch) layer of crushed stone (38 millimeters [1.5

inches] minus) over the backfill material. Place and compact the crushed stone material

in lifts approximately 152 millimeters (6 inches) thick. Compact each lift of crushed

stone using a minimum of four passes of a single drum vibratory roller or two passes

with a 10-ton vibratory roller per each 152-millimeter (6-inch) lift. One pass of the roller

means traveling across and back in the same lane. If the crushed stone material is

placed upon soft subgrade materials, it may be beneficial to separate the crushed stone

from the backfill with a geomembrane and to place the crushed stone material in thicker

lifts. In any case, the crushed stone should be compacted with a minimum of four

passes of a single drum vibratory roller or two passes of a 10-ton vibratory roller per

each 152 millimeters (6 inches) of thickness. A 304-millimeter (12-inch) crushed stone

layer should receive a minimum of eight passes with a single drum vibratory roller, or

four passes with a 10-ton vibratory roller. This crushed stone material must be

compacted to a minimum 25 CBR.

2-2.4.3.13 Place a layer of sand approximately 304 millimeters (12 inches) wide by 25

to 50 millimeters (1 to 2 inches) deep around the entire inside of the crater's lip to

prevent seepage of the grout around the edge of the crater.

2-2.4.3.14 Position a layer of impervious membrane material over the entire crushed

stone surface.

2-2.4.3.15 Place a 203-millimeter (8-inch) layer of grout material mixed in accordance

with Table 2-2 into the crater.

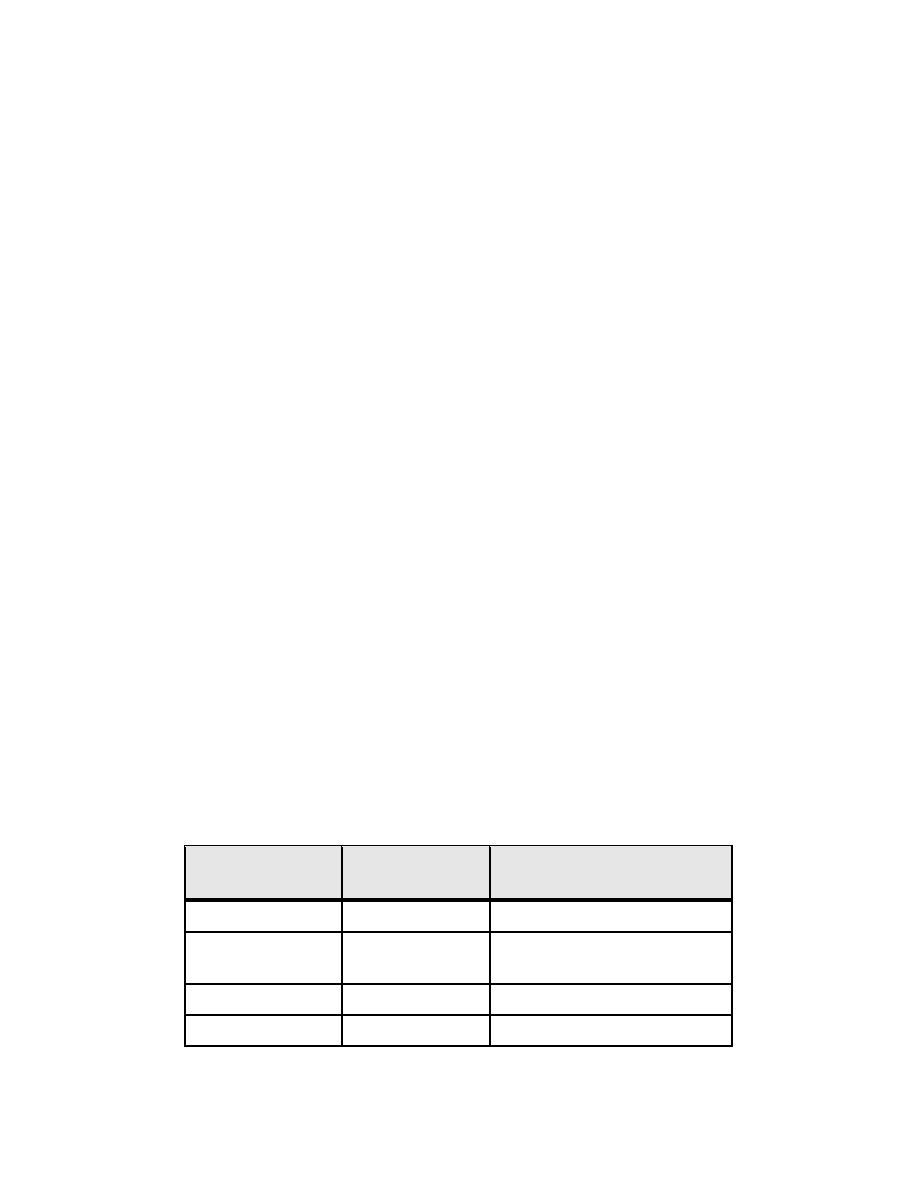

Table 2-2. Stone and Grout Mix Proportions

Percentage by

Weight of Additive Per

Grout Mixture

Weight

Cubic Yard

Portland cement

67.8

22.3.2 lb (999.4 kg)

Calcium chloride

1

32.67 lb (14.8 kg)

(accelerator)

Friction retarder

0.2

6.68 lb (2.9 kg)

Water

31

1004.4 lb (455.6 kg)

Note: This mixture will develop a compressive strength of at least

1500 pounds per square inch (psi) in 24 hours

2-10

Previous Page

Previous Page