UFC 3-260-11FA

25 May 2005

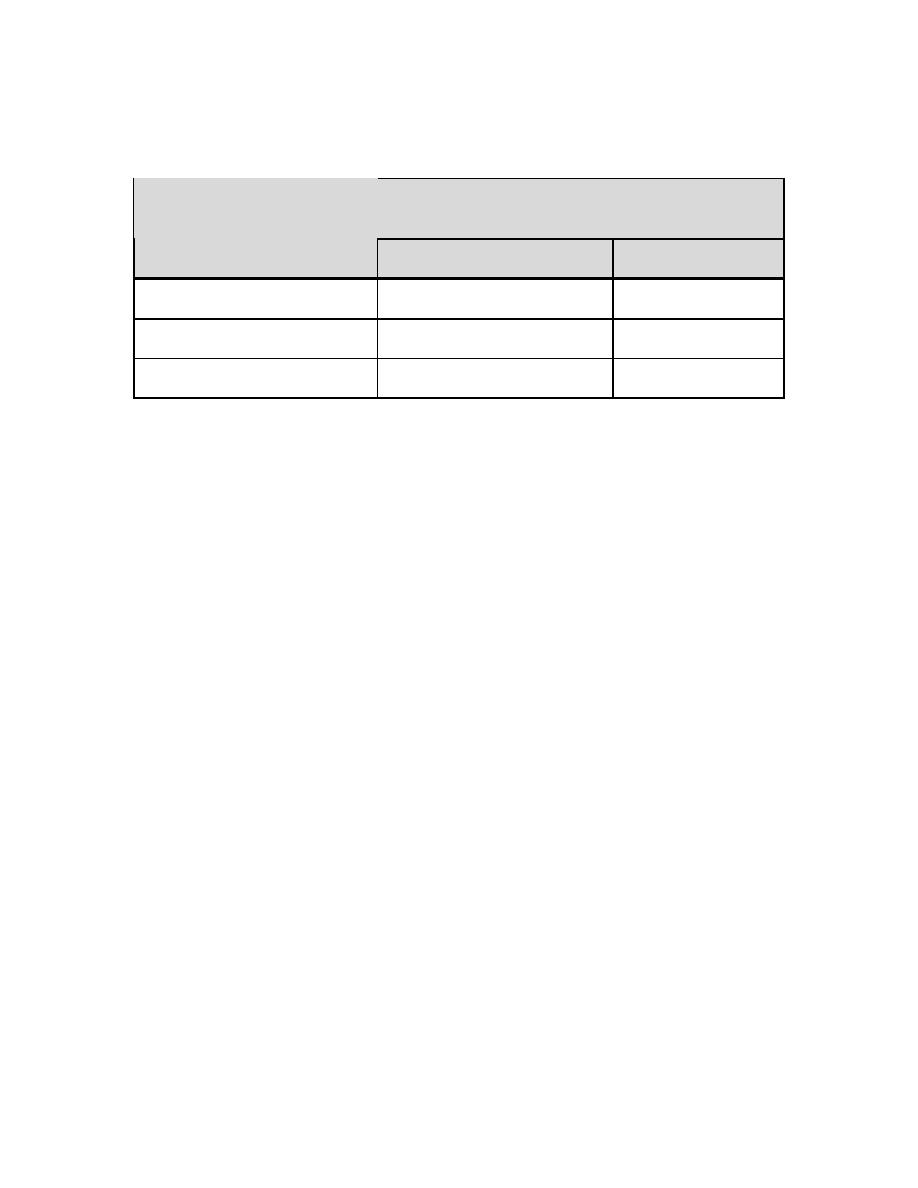

Table 3-4

Transverse Joint Spacing

Joint Spacing

Pavement Thickness

Meters (Feet)

Millimeters (Inches)

Army and Air Force

Navy

Less than 230 (9)

3.8 to 4.6 (12.5 to 15)

4.6 (15)

230-305 (9 to 12)

4.6 to 6 (15 to 20)

4.6 (15)

Over 305 (12)

6 (20) max

4.6 to 6 (15 to 20)

NOTE: For Navy pavements, transverse joint spacing cannot vary more than 25

percent of longitudinal joint spacing.

3-6.10.2.2 Longitudinal Joint Spacing. (See UFC 3-260-02.) For the Army and Air

Force, if the paving lane width exceeds the joint spacing criteria in Table 3-4, a center-

sawed contraction joint is required.

The standard panel size for Navy pavements is 3.8 by 4.6 meters (12.5 by 15 feet), with

longitudinal joint spacing of 3.8 meters (12.5 feet). For pavements having a thickness

greater than 300 millimeters (12 inches), joint spacing can be increased to a maximum

of 6.1 meters (20 feet).

3-6.10.2.3 Expansion Joints. (See UFC 3-260-02.) Expansion joints should be used

in these areas:

At intersections of pavements with structures.

At non-perpendicular pavement intersections.

Between old and new pavements with non-aligned joints.

3-6.10.3

Load Transfer. (See UFC 3-260-02.) When properly designed and

constructed, most joints provide load transfer from one slab to the adjacent slab. Load

transfer efficiency is usually the ratio of deflection of the unloaded side to the deflection

of the loaded side of a joint. Most pavement design assumes a load transfer of 25

percent. Different amounts of load transfer can be obtained through the use of

aggregate interlock, dowel bars, keyways, a stabilized base, or a combination of

approaches.

3-6.10.3.1

Types of Load Transfer

Aggregate Interlock. Partial depth sawing of contraction joints results

in the formation of a crack for the unsawed depth that provides

aggregate interlock. Undowelled contraction joints rely on aggregate

27

Previous Page

Previous Page