TM 5-822-13/AFJMAN 32-1018

e. Example No. 3.

(1) To illustrate the design procedure for tracked vehicles, it is assumed that a concrete pavement is to be

designed for an average of 10 M1 tanks per lane per day. The Ml tank has the following characteristics:

Gross weight

120 kips

Track spacing (c to c)

112 inches

Track width

25 inches

Track contact width

18.75 inches (= 0.75 x 25)

Track length

180 inches

Number of bogies per track

7.0

Operations per coverage ratio

0.33 (from table 5-1)

(2) To use computer codes such as the JULEA computer program, the track load will be converted into

eight uniformly distributed circular loads. Each circle has a diameter of 17.25 inches (the width of the track) and

a load of 7,500 pounds. The distance between bogies is 20.4 inches center to center. The computed maximum

stresses for several concrete thicknesses are tabulated in column 2 of table `7-3. The maximum stress in this case

occurs under the center load. In other cases, the location of the maximum stress needs to be determined. This is

done by computing stresses in many locations and selecting the maximum stress. Following the procedures in

example 2, a plot of concrete thickness (column 1) against damage (column 6) shows that the design concrete

thickness is 13.7 inches. This thickness value would be rounded off to 14.0 inches for design.

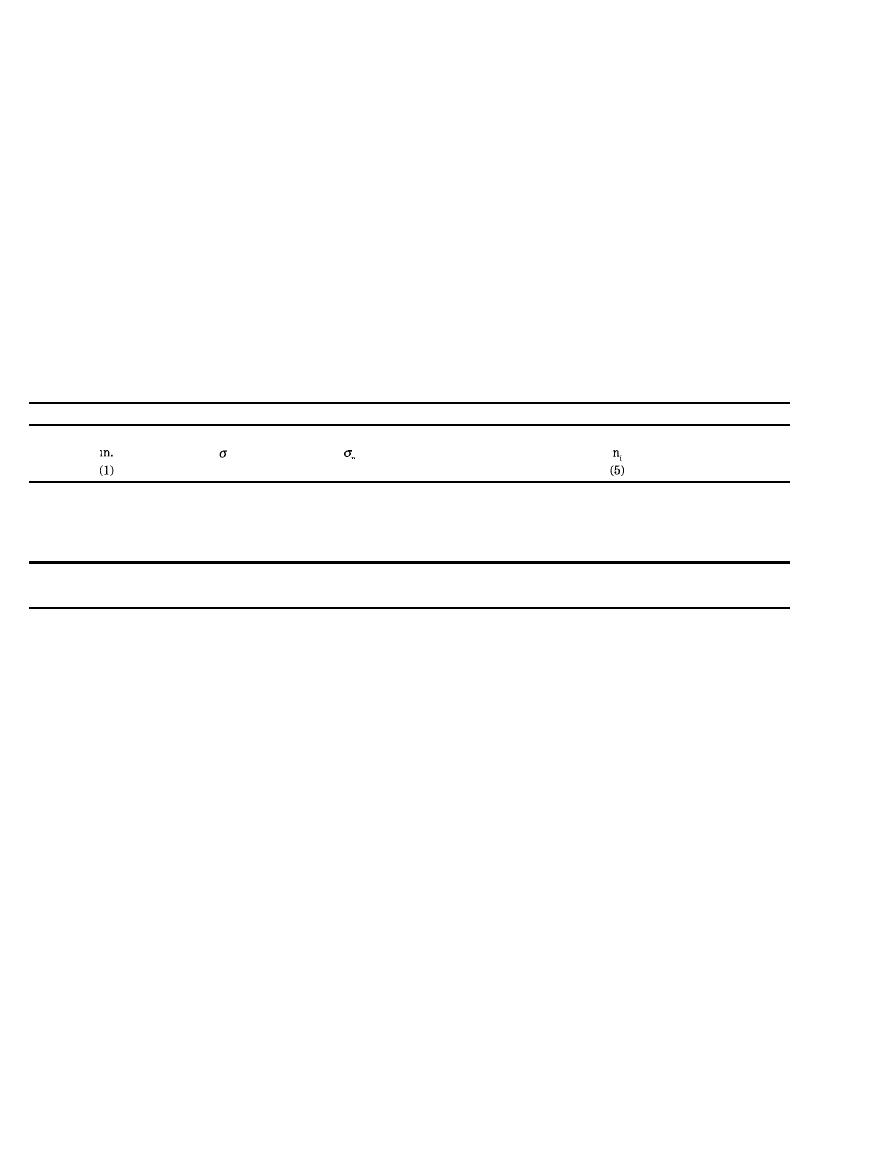

Table 7-3. Cumulative Damage Computed for M1 Tank.

Slab Thickness

Maximum Stress

Allowable* Coverage

Damage

Design ** Coverage

ni/Ni

1.33 x

max

max

Ni

(2)

(4)

(3)

(6)

8

347

461.5

329

273,204

830

10

275

365.8

3,124

273,204

87

12

224

297.9

37,137

273,204

7.4

14

185

246.1

615,013

273,204

0.4

*SCI = 80, R = 625 psi.

**Design coverages for 25 years is 25 x 365 x 10/0.33 = 273,204.

f. Example No. 4. To illustrate the procedure for conventional traffic plus forklift trucks and tracked ve-

hicles, design a concrete pavement road for the following traffic:

Passenger cars

300 per

lane

per

day

Panel and pickup trucks

200 per

lane

per

day

Trucks, 2-axle

100 per

lane

per

day

Trucks, 3-axle

40 per

lane

per

day

Track-laying vehicles, 120,000 pounds (Ml tank)

2 per

lane

per

day

Forklift trucks, 25,000 pounds (Pneumatic tires)

20 per

lane

per

day

Table 7-4 shows the design coverages for each wheel or track configuration, and table 7-5 shows the computed

maximum stresses and damage. The cumulative damage for concrete thicknesses of 8, 10 and 12 inches is 34.2,

3.4 and 0.3, respectively. A plot of these values indicates a required concrete thickness of 11.2 inches for a dam-

age of one. This thickness value would be rounded off to 11 inches for design.

7-6. Joints.

The design and construction of joints for plain and roller-compacted concrete, the design and installation of

dowel bars, special provisions for slipform paving, and joint sealing are presented in TM 5-822-5/AFM 88-7,

Chap. 3.

7-7. Design Details.

Typical details for the design and construction of plain concrete pavements are contained in TM 5-822-5/AFM

88-7, Chap. 3.

7-6

Previous Page

Previous Page