TM 5-822-12

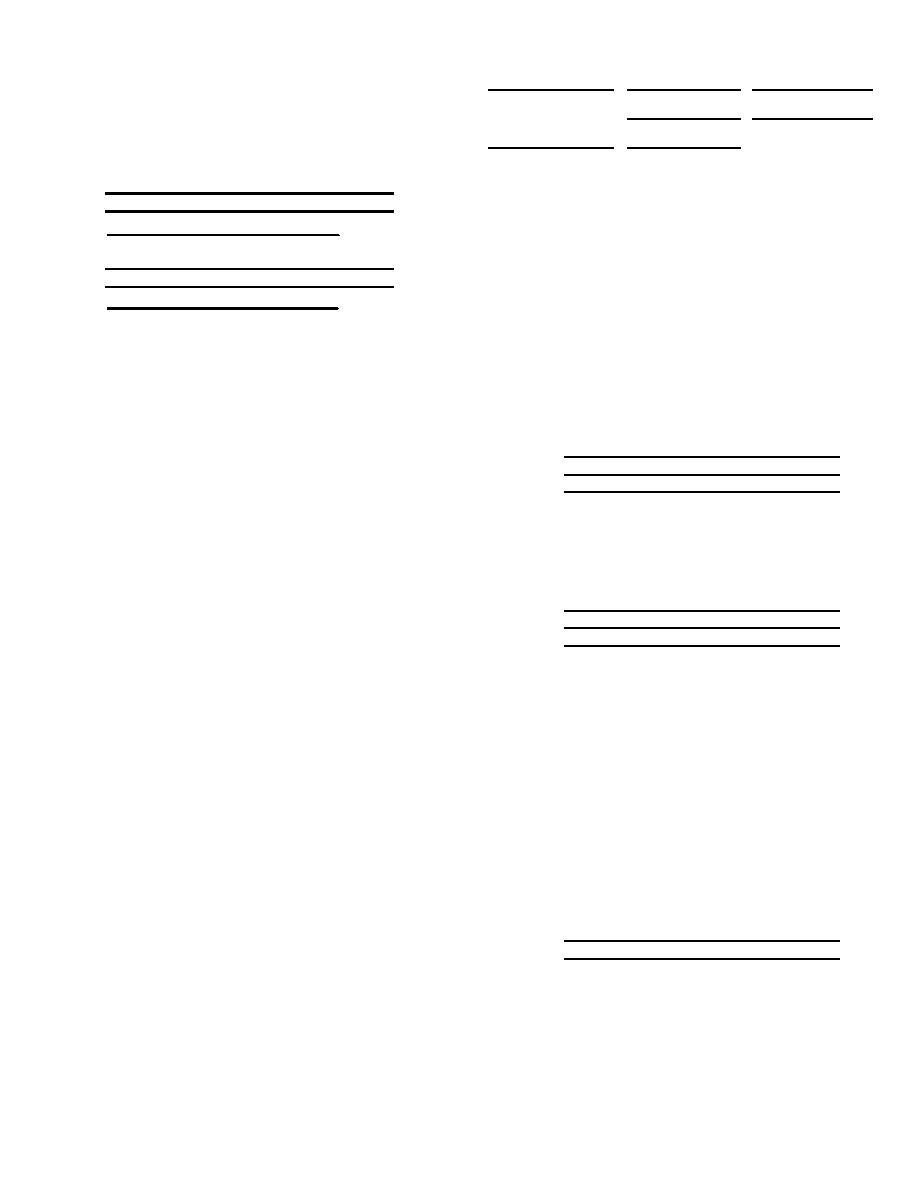

(4) Using geotextiles. Either of the designs

shown above could be used by deducting 6 inches of

12.0 inches crushed

4 inches crushed

7 inches crushed

rock

rock

rock

well-graded sand subbase and replacing it with a

8.0 inches sand

Compacted

geotextile. The total thickness above the geotextile

subbase

subgrade CBR = 8

must be a minimum of 15 inches. Alternative designs

Subgrade CBR = 4

Subgrade CBR = 4

using a geotextile might be:

b. Determine the cross section in a severely cold

4 inches fine-graded stone

area where subgrade freezing is predicted.

11 inches coarse-graded crushed stone

geotextile

(1) Only the wearing surface and base course

Subgrade

layers will apply in this section. The sand subbase is not

or

required because the subgrade is not cohesive. The

7 inches fine-graded stone

filter fabric will not be used because the subgrade soil is

8 inches well-graded sand

an F2 material and the use of this fabric is restricted to

geotextile

Subgrade

F3 and F4 subgrade soils.

(2) In this case the natural subgrade CBR of

Notes:

4 is less than the frost-area soil support index and will

-All layer depths should be rounded up to the next

govern the design. The total thickness required above a

full inch for construction purposes.

subgrade CBR = 4 is 12.0 inches.

-The granular layers should be compacted to 100

(3) Therefore, the cross section for this

percent CE 55 maximum density.

condition will be:.

-The subgrade should be compacted to the density

required by table 8.

4 inches fine-graded stone

-The material should meet the gradation

8.0 inches coarse-graded crushed stone

requirements shown herein.

Subgrade CBR = 4

-The frost group soils F1l and F2 used as base and

c. Based on economic considerations, alternative

subbase materials should meet the requirements in

sections may be developed using frost group soils S1,

the appropriate guide specifications.

S2, and F1 with lower portion of the base material. An

-As previously stated, after all possible design

example using F1 soils is as follows:

sections are determined, the final section used for

the tank trail should be determined on the basis of

7.0 inches fine-graded stone

an economic analysis.

5 inches frost group soil Fl

Subgrade CBR = 4

14. Design Example No. 2. Assume the following

conditions:

15. Design Example No. 3. Assume the following

conditions:

CBR values.

-Natural subgrade = 4 (SM - silty sand material, frost

Design is for Army Class III airfield.

group F2).

Traffic protection = 10,000 passes of C-130 aircraft.

-Compacted subgrade = 8.

Design gross weight = 135 kips.

-Fine-graded crushed rock wearing surface = 80.

CBR values.

-Course-graded crushed rock base course = 80.

-Subgrade = 6

-Clean sand subbase = 15.

-Crushed stone = 80

Projected traffic.

Enter figure 4 with the subgrade CBR of 6, the 135 kip

-2,500 operations per day of Category IV traffic.

gross weight and 10,000 passes, and read the thickness

Calculations:

required above the 6 CBR of 13.5 inches which when

a. Determine the required thickness. From table 1

rounded to the next full inch will be 14.0 inches. The

determine the road to be a Class D road. From table 3,

section therefore would be:

select a design index = 5. From the design curves

(figure 1) the required thickness above the natural

14.0 inches of crushed stone

subgrade with a CBR of 4 is 11.5 inches (round to next

Subgrade CBR = 6

full inch of 12); the required cover over the compacted

subgrade (CBR = 8) is 7 inches. Therefore, the

hardstand might have the following cross sections:

14

Previous Page

Previous Page