TM 5-822-12

consist of base and subbase material provided the top 6

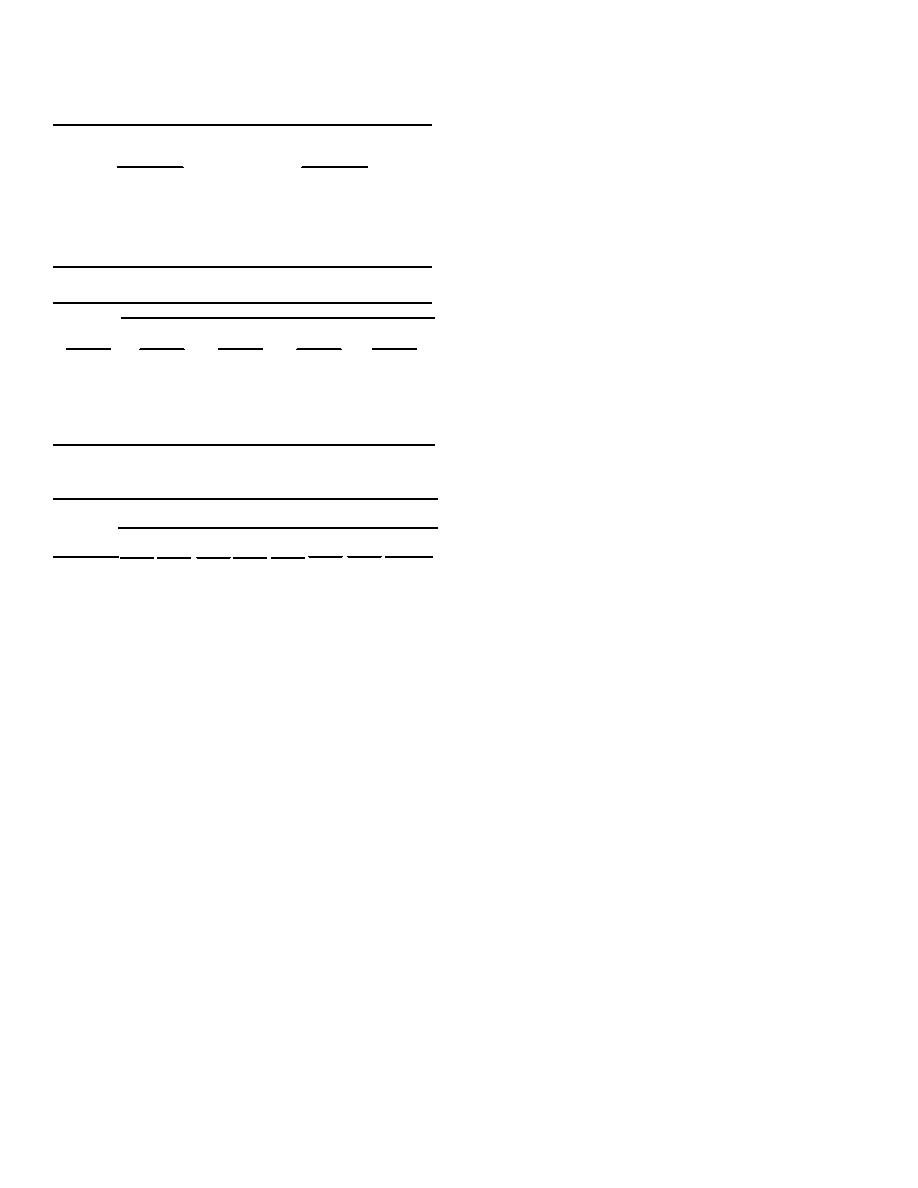

Table 1. Criteria for selecting aggregate surface road

inches meet the gradation requirements in paragraph 8.

class.

Number

Road

of Vehicles

5. Design of aggregate surfaced airfields

Class

per day

The thickness design of aggregate surfaced airfields is

A

10,000

similar to the design of flexible pavement airfields as

B

8,400-10,000

contained in TM 5-825-2. This procedure involves

C

6,300-8,400

D

2,100-6,300

assigning a class to the airfield based upon the aircraft

E

210-2,100

controlling the design. Having selected the class of

F

70-210

airfield, the design is accomplished using figures 2

G

under70

through 4.

Table 2. Design index for pneumatic-tired vehicles.

a. Classes of airfields. There are four classes of

Design Index

Army airfields. These are Classes I-IV, although only

Category

Category

Category

Category

Class

I

II

III

IV

Classes I-III are considered candidates for aggregate

A

3

4

5

6

surfacing. Each class of airfield is designed for a

B

3

4

5

6

standard loading condition and pass level as defined in

C

3

4

4

6

TM 5-803-4.

Where necessary, airfields may be

D

2

3

4

5

designed for loads and pass levels other than the

E

1

2

3

4

F

1

1

2

3

standard, and the criteria herein provide thicknesses for

G

1

1

1

2

varying pass and load levels.

Table 3. Design index for tracked vehicles and forklift

b. Traffic areas. Army airfields are divided into

trucks.

traffic areas for design purposes. Type B traffic areas

Number of Vehicles per Day

consist of taxiways, the first 1,000 feet of runway ends,

Traffic

(or Week as indicated)

and aprons. Type C traffic areas are the interior

Category

500

200

100

40

10

4

1

1 Per

portions of the runway (between the 1,000 foot runway

Week

V

8

7

6

6

5

5

5

-

ends).

VI

-

9

8

8

7

6

6

5

VII

-

-

10

10

9

8

7

6

c. Thickness criteria (nonfrost areas). Thickness

requirements for aggregate surfaced airfields are

often has greater impact than localized failure on the

determined from figures 2 through 4 for types B and C

hardstand itself. Since these areas will almost certainly

traffic areas.

Thicknesses for type B areas are

be subjected to more frequent and heavier loads than

determined directly from the curves, and type C traffic

the hardstand, the design index used for the primary

areas are designed using 75 percent of the load used to

road should be used for entrances and exits to the

design type B traffic areas. The minimum thickness

hardstand. In the case of large hardstands having

requirement for all cases will be 4 inches. The figure for

multiple use and multiple entrances and exits,

the appropriate airfield class will be entered with the

consideration should be given to partitioning and using

subgrade CBR to determine the thickness required for a

different classes of design. The immediate benefits that

given load and pass level. The thickness determined

would accrue include economy through elimination of

from the figure may be constructed of compacted

overdesign in some areas and better organization of

granular fill for the total depth over the natural subgrade

vehicles and equipment.

or in a layered system of granular fill and compacted

subgrade for the same total depth. The layered section

i. Thickness criteria (nonfrost areas). Thickness

should be checked to ensure that an adequate thickness

requirements for aggregate surfaced roads are

of material is used to protect the underlying layer based

determined from figure 1 for a given soil strength and

upon the CBR of the underlying layer. The granular fill

design index. The minimum thickness requirement will

may consist of base and subbase material provided the

be 4 inches. Figure 1 will be entered with the CBR of

top 6 inches meet the gradation requirements of

the subgrade to determine the thickness of aggregate

paragraph 8.

required for the appropriate design index. The thickness

determined from the figure may be constructed of

6. Design CBR for select materials and subbases

compacted granular fill for the total depth over the

Design CBR values and materials requirements for

natural subgrade or in a layered system of granular fill

select materials and subbases are to be selected in

(including subbases) and compacted subgrade for the

accordance with TM 5-825-2 except as modified in table

same total depth. The layered section should be

4.

checked to ensure that an adequate thickness of

material is used to protect the underlying layer based on

the CBR of the underlying layer. The granular fill may

5

Previous Page

Previous Page